Lihao is a very useful cut to length machine that can be beneficial for you if you are handling coiled material in your factory. The typical design of a tape measure is to have a flexible metal or plastic flat strip with linear-measure markings. Well, this specific device has been specifically designed to accomplish mechanically slicing via these supplies at speedy charges to frivolously divide them into smaller lengths defensively. Length, after all, is directly relevant to the factory — these are a perfect fit for their product. If your materials are too long, they will not fit correctly. Anything shorter and they will sit idle. The coil cutting machine examples are a great invention of this machine to keep everything on the go.

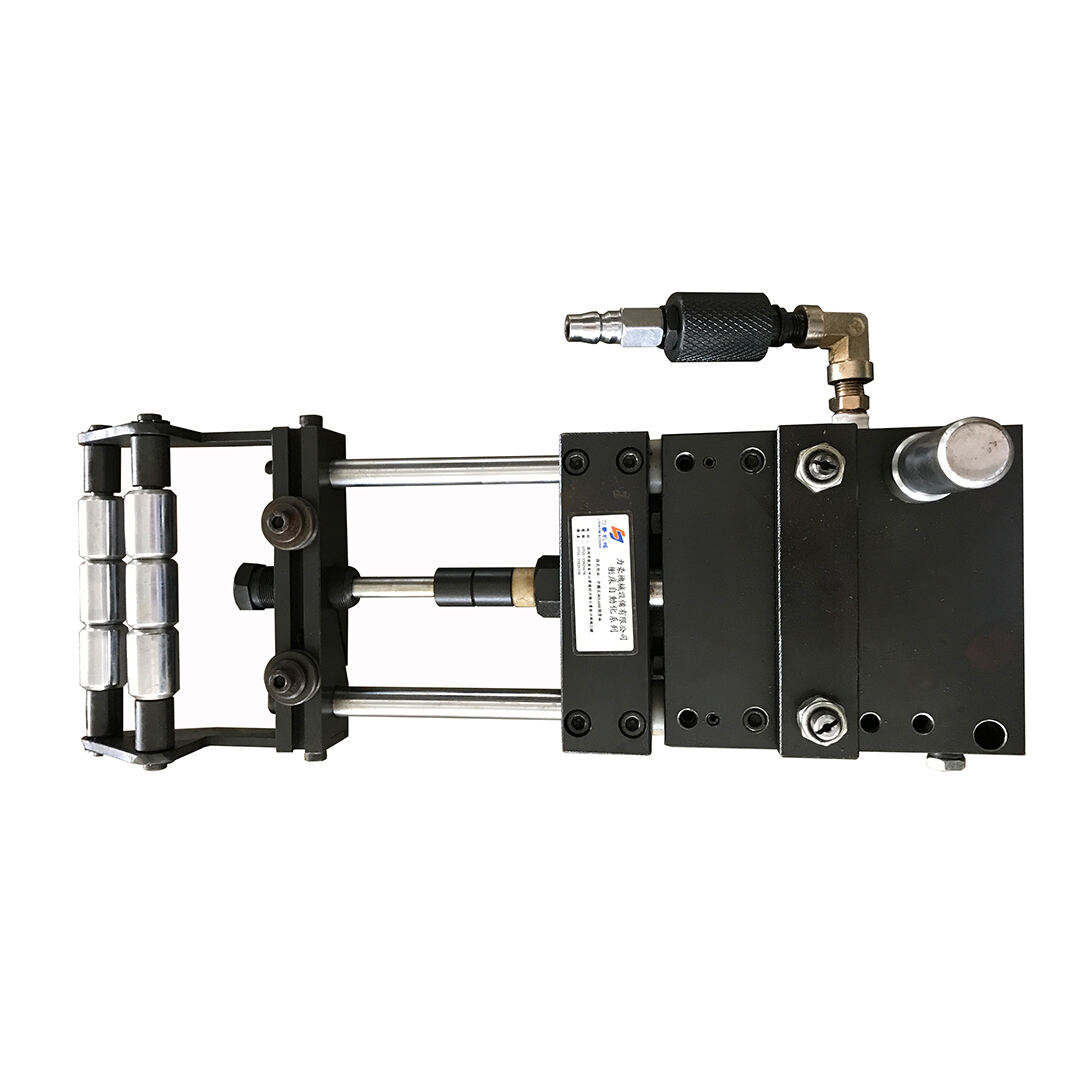

The machine as the coil cut to length machine will work very fast and it is also high in accuracy. Precision shows that the cuts are made properly, which means that with every pass through the factory gate, a correct length is obtained. This servo feeding line is also a very good thing for a factory to get and use so they can be better at what they do or more efficient. Which, in turn, means the factory is not spending time and money correcting errors when it comes to cutting up the materials. Instead, they devote more time to a product development and timely delivery. This is why all cuts of presence within the factory are processed using a precise cutting machine.

WinTek machines make manufacturers more efficient and better factories. For starters, when factories run more efficiently, they can produce more products, faster and at a lower cost. This Coil Feed Line machine is also time-saving and it has little chance of mistakes as well. Cutting the material by hand is not only a laborious task, but also prone to human error that creates hours of additional work on top of cutting itself. This means the plant is able to increase its production rate without having to lower it down. Altogether, this sort of machine should ease items and make all job possible more accurate.

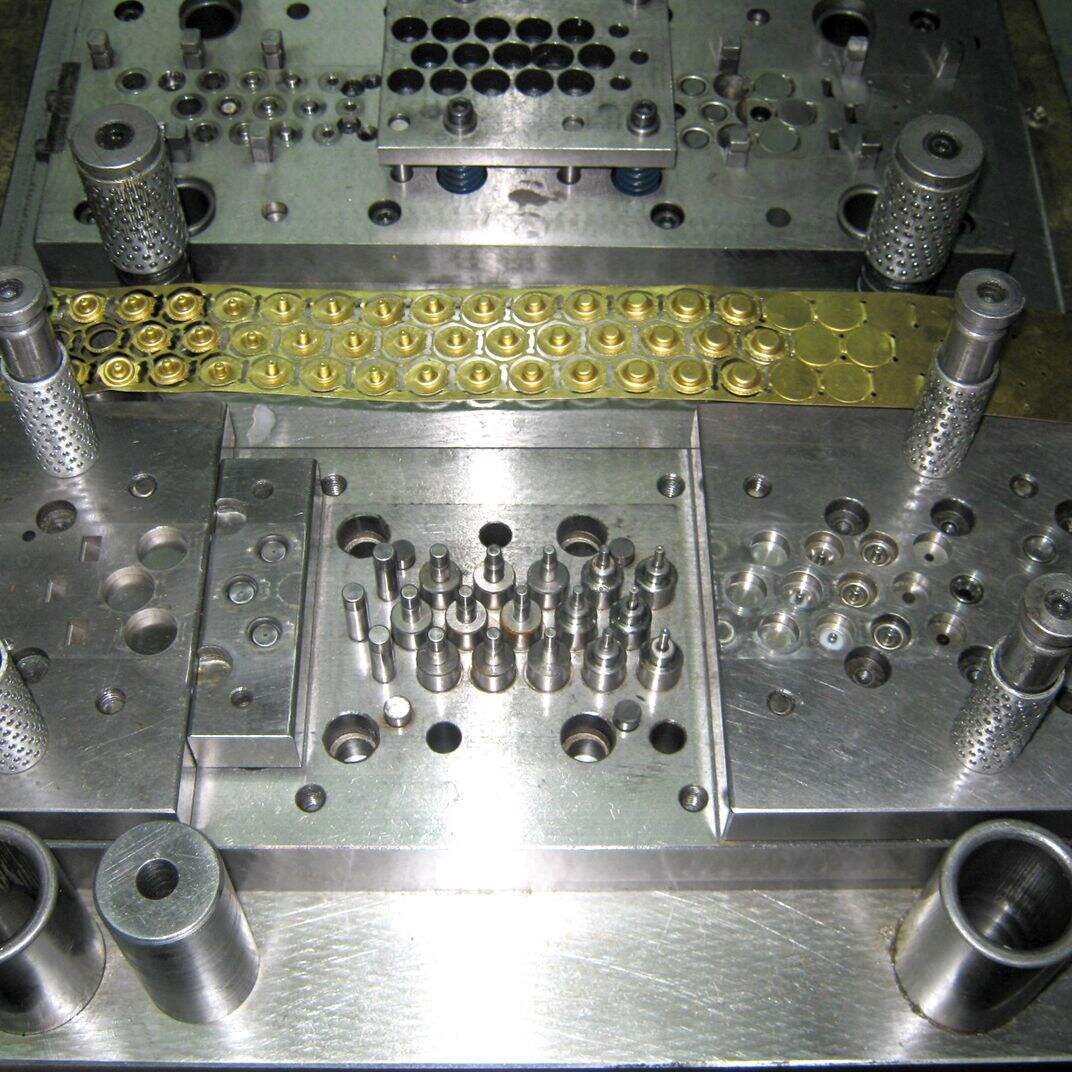

No two factories are the same and likewise they all have different requirements with regards to cutting type. Coil Cut to length is sensor controlled machine. you can set how many times to cut one material, as well other cutting styles according necessary if is another materials injured at the same cut to lenght line. It Coil Line Systems means you can slice the pie made of any manufacture, to fit your product just right. It also means that it may perhaps possibly use a range of sources mainly the reason that this machine is multipurpose and productive on numerous kinds of rolls. This versatility is important since that enables the machine to be used in a huge range of factories, turning it near to an universal tool.

Because machines are much faster and will rip through materials, the difference in how much material is wasted with hand cutting vs machine cutting is stark. This allows factories to salvage materials and also save the cost! It press feeding line can cut very fine wires to allow the manufacturers to cut costs and avoid losses due to it. That way, factories use up as much as possible of the materials they already purchase less. Smart busines and smarter enviroment.

We are specialists into the design and development of strong tooling, that can help to reduce setup adjustments as well as reduces scrap production. Our Coil cut to length machine offer global training and commissioning, ensuring performance that is maximum integration worldwide this is certainly seamless. In-house manufacturing and top-quality spare parts provider we could guarantee downtime which is maximum productivity that is minimum. Certified and ISO9001:2000 and EU CE We uphold the standards that are standard are greatest.

Lihao Machine is a huge business is leading the industry because 1996. It is only a trusted supplier both the national and international markets. Our products are trusted in lots of industries throughout the world. All over the globe with over twenty offices in China and an overseas branch in Asia We provide our customers. We offer tailored solutions throughout various industries with this robust technological capabilities.

Our dedication to quality, reliability and continual improvement of our services plus products is an ongoing procedure. Our Lihao team is highly trained and certainly will provide cutting-edge solutions. Our company is the true number one option for stamping automation. We place a high benefits customer satisfaction, offering top-quality products and superior services consistently.

Lihao Machine offers tailored solutions comprehensive services to fulfill various customer. We offer integrated solutions which include design, production and product sales. Our R&D team is specialized in offering modification as well as technical discussion, making certain each solution is designed to meet your requirements.