We have modern machines with smart software in our cutting lines. This software assists in the making of these machines to make precise cuts which is essential to creating quality products. With our cutting line technology, businesses can have high confidence that their metal coils will be cut to perfection. This leads up to products being shipped not only as anticipated but also surpassing customers want.

Hand cutting metal coils can be time-consuming and very labor-intensive. It can be a tough job! Well, not with our cutting line machines — they save on time and make the whole process as efficient as possible. These are some of the most common needs and applications that we have machines available for, capable of cutting bulky metal coils into smaller pieces fast and accurately.

The software and materials used in each one of these machines are advanced and high-quality to make sure that every single cut is as precise as possible. So this also allows businesses to operate more quickly and efficiently. This, in turn, can significantly decrease the time it takes to manufacture their products and increase the number of units produced throughout a day.

Our high-precision technology enables businesses to enjoy increased accuracy and consistency from the assembly phase. This increases the likelihood of avoiding errors or issues such as process delays. With revolving times of producing their products much faster and efficiently, businesses are able to be ahead of its competitors and provide customers with what they want in no time.

Restores And Consistency One of the greatest advantages that you could get from utilizing cutting line gear are affectability and conformability. We build machines to extremely precisely cut metal coils. This makes sure every cut is the same as last, A vital factor. Producing things to a certain level of quality diminishes the likelihood of any defect or issue with product.

A business today needs to ensure that it makes the best use of every resource that it can. This is why our cutting lines are purpose built with a mind to production efficiencies, helping you maximise every unit of your material, and at Lihao we get this. We set our machines to cut metal coils in a way that minimizes waste. This makes sure that businesses maximise the use of their materials.

Maximizing material yield means that businesses have less waste, and that can help them increase their profitability. It means that they will be able to create a more substantial amount of products with the same level of raw materials. In a world where doing more with less — time, talent, or budget — is paramount to market competitiveness and profitability, companies everywhere need to perform better.

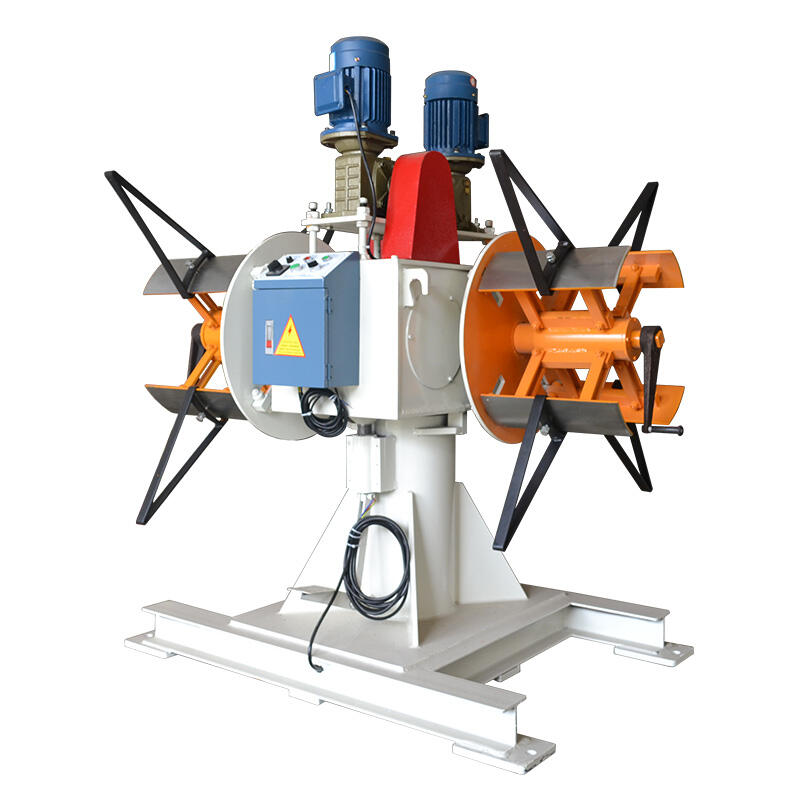

Lihao Machine offers tailored solutions along with a wide range of services to fulfill various customer. With a broad variety of merchandise, including 3 within one feeders, Decoiler Cum Straightener machines, NC servo feeders, and punch machines, you can expect integrated service covering manufacturing design, sales, service, and trading. Our R&D team is dedicated to ensuring customization and technical discussions, ensuring that each product was designed to hook up together with your unique specifications.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our coil cutting line offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.

Our dedication to quality, improvement and continuous reliability of products and service is a constant. Our Lihao team is extremely skilled and offers cutting-edge systems. Our company is the stamping possibility first automation. We have been focused on client satisfaction, providing top-quality products outstanding service.