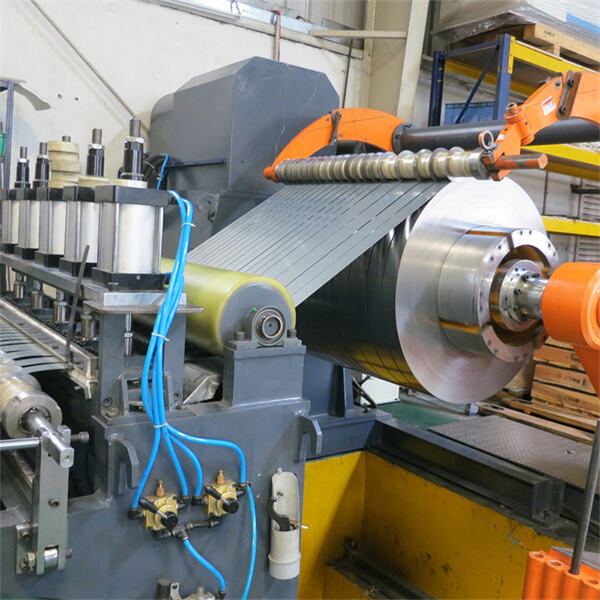

The Coil Feed Line is a specialized process for cutting large metal coils into smaller coils. This is extremely beneficial as the smaller rolls are more user-friendly and can be used for a variety of products. This cutting method is particularly vital in businesses such as including car manufacturing, construction, along with the production of electrical home appliances. Metal is one material that is used in many ways in these industries.

One will become more proficient at coil slitting called Lihao They are famous for offering excellent solutions to cut metals that can be adapted to the varied requirements of their clients. Lihao speeds up the process of creating metal products for many businesses and makes it easier. They know what will make coil slitting most efficient for various forms of metal and various kinds of machines in need of metal components.

Since Coil Line Systems is useful for factories manufacturing different products. The biggest advantages are that it helps to use materials more efficiently. With high treadmill coil slitting technology, Lihao assists manufacturers in cutting every metal roll to their required size. It contributes less to resource waste, which is more environmentally friendly and costs less.

One more major benefit of coil slitting is that it can save companies money. Coil slitting is faster and more efficient than cutting metal sheets individually. That allows factories to produce their goods more quickly and spend less on labor costs. This kind of customized help is even better for production because manufacturers can order any size they need and no longer need to worry about ordering too little or too much metal, thanks to Lihao's solutions.

Lihao is specialized in precision coil slitting, so they are particularly good at making sure that the cuts are accurate. Their solutions are tailored to the unique requirements of every customer. To do this, the company employs sophisticated computer technology to slice each metal coil to a high degree of precision. This is to reduce the volume of wasted material during the cutting process.

Lihao stands out for its advanced coil slitting solution. We encourage you to continue visiting our website for frequent updates on slitting in the high-volume manufacturing operations. Their brilliant techniques make them as efficient as possible, letting them pass large quantities of metal coils in a rapid and fluid manner.

The company uses advanced machines, such as high-speed computer-aided slitters. This equipment guarantees that the cutting process is performed to exact dimensions, so that all orders are manufactured precisely to specification. Manufacturers who are required to meet precise conditions for their products rely on this accuracy.

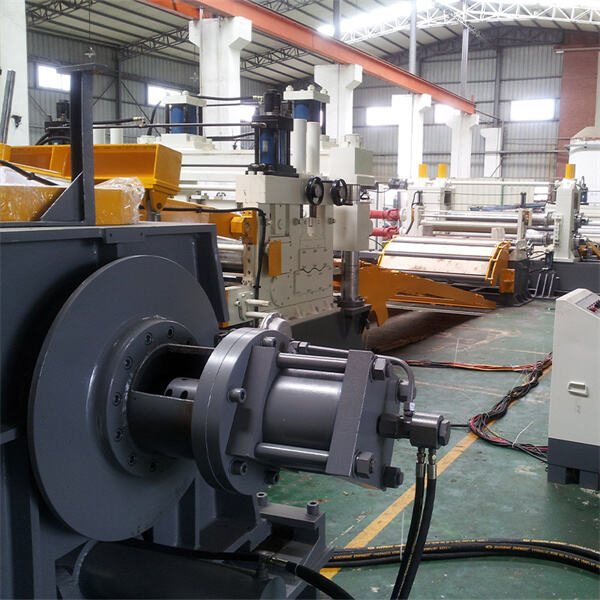

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.

Our dedication to quality, reliability and continual improvement of our services plus products is an ongoing procedure. Our Lihao team is highly trained and certainly will provide cutting-edge solutions. Our company is the true number one option for stamping automation. We place a high benefits customer satisfaction, offering top-quality products and superior services consistently.

Lihao Machine happens to be the marketplace leader for 26 ages. It's the trusted provider both domestic and international markets. Our items are extensively utilized in many industries throughout the world. We offer our customers throughout the global world with nearly 20 offices in China and an indian branch. We offer tailored systems around many industries using our advanced technological capabilities.

Our company is specialists in engineering and design that is robust of, which helps in reducing alterations to setup and scrap production this is certainly decreasing. Our coil slitting offer worldwide training and commissioning, ensuring the performance which was highest and integration that is seamless the whole world. With our own manufacturing business and high-quality spare parts support we could guarantee minimum downtime and productivity which are high. Our company is ISO9001:2000 certified in addition to EU CE approved.