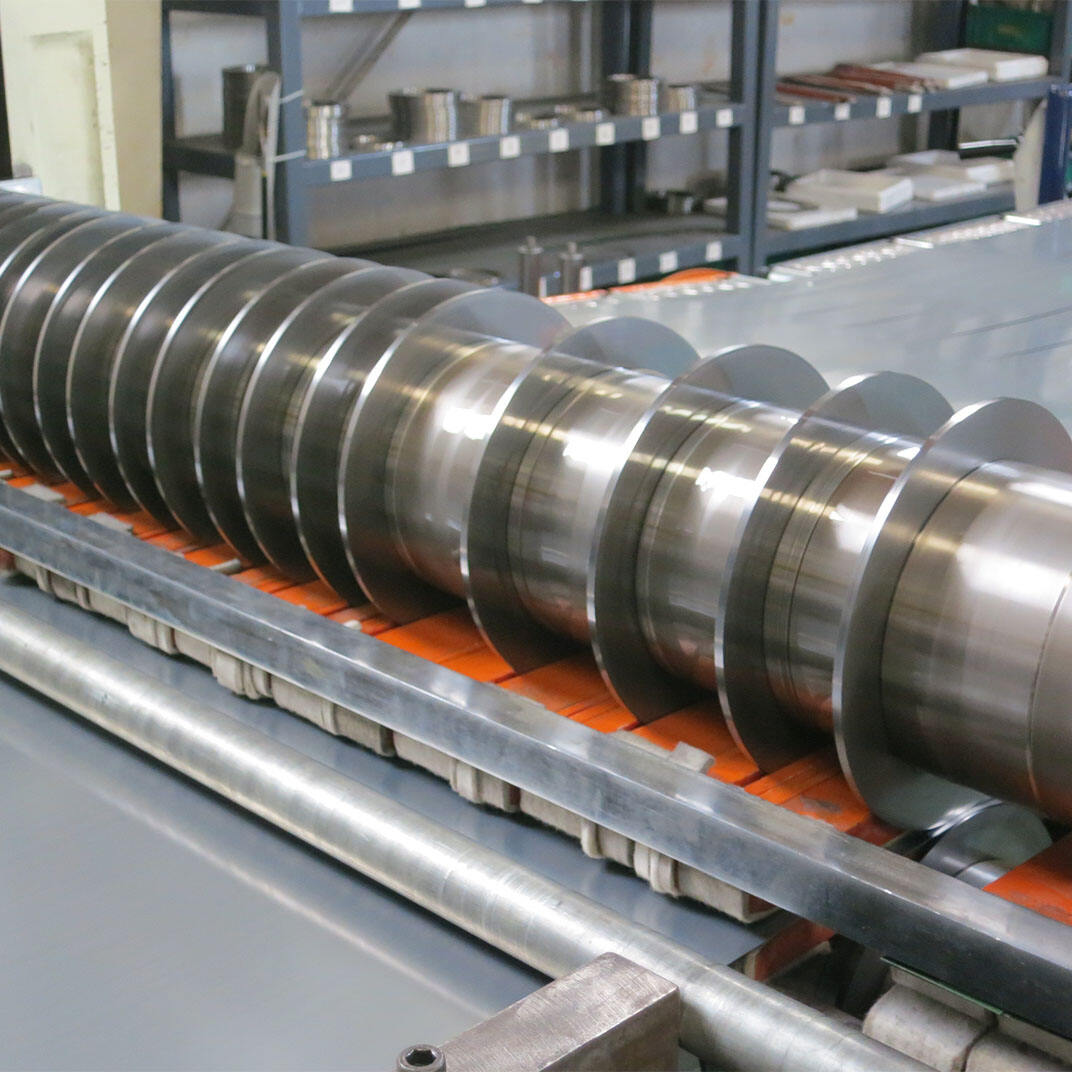

The two types of machines which play havoc in the world of metal productions, despoilers and feeders. The form is central to industrial metal production. In this article, we will delve deeper into the working of these machines and how they are beneficial. One of the machines that is completely sold and used by every press shop is known as DE, these are special machines that ensure that metal coils are straightened for use in producing parts. Sometimes when metal comes in coils it is all twisted and messed up. These coils are carefully unwound by DE, in order that they can go into other machines for more work. Through this, the despoilers play a role in making the procedure of metal working faster and better. They work to ensure that everything is lined up correctly so the next steps in metal production can go off without a hitch. Using metal coils would be much more difficult without the use of despoilers.

Feeders are the same machines and machines feed the most important in metal production. They also work really hard to make sure all the materials continue down the line at a constant pace (it is important that everything functions well.). Ensuring the materials flow at an even rate, means that mistakes can be avoided as when things are rushed or slowed to much mistakes typically will occur. Feeders work like a conveyor belt making sure that the material is passed along so production will not need to wait for the next machine. In this way the whole process of metal production is not hindered and kept in course.

Machines like despoilers and feeders can have a metal working process so much better. Automating these machines means that they can work without the need of manual intervention, allowing people to save time and physical labor as the machine can do a monotonous task. To have made the whole process faster and avoid carelessly mistakes, simply using Automation. Mistakes are the root of all evil in any field, and when it comes to media production well that is a really bad blow nobody wants. Ultimately, the end of automation is fewer employees required to sit there and monitor the machinery and thus it can also save money. In other words, metal fabrication businesses can spend more of their time making sure they create products to the best standards possible in place of worrying about errors.

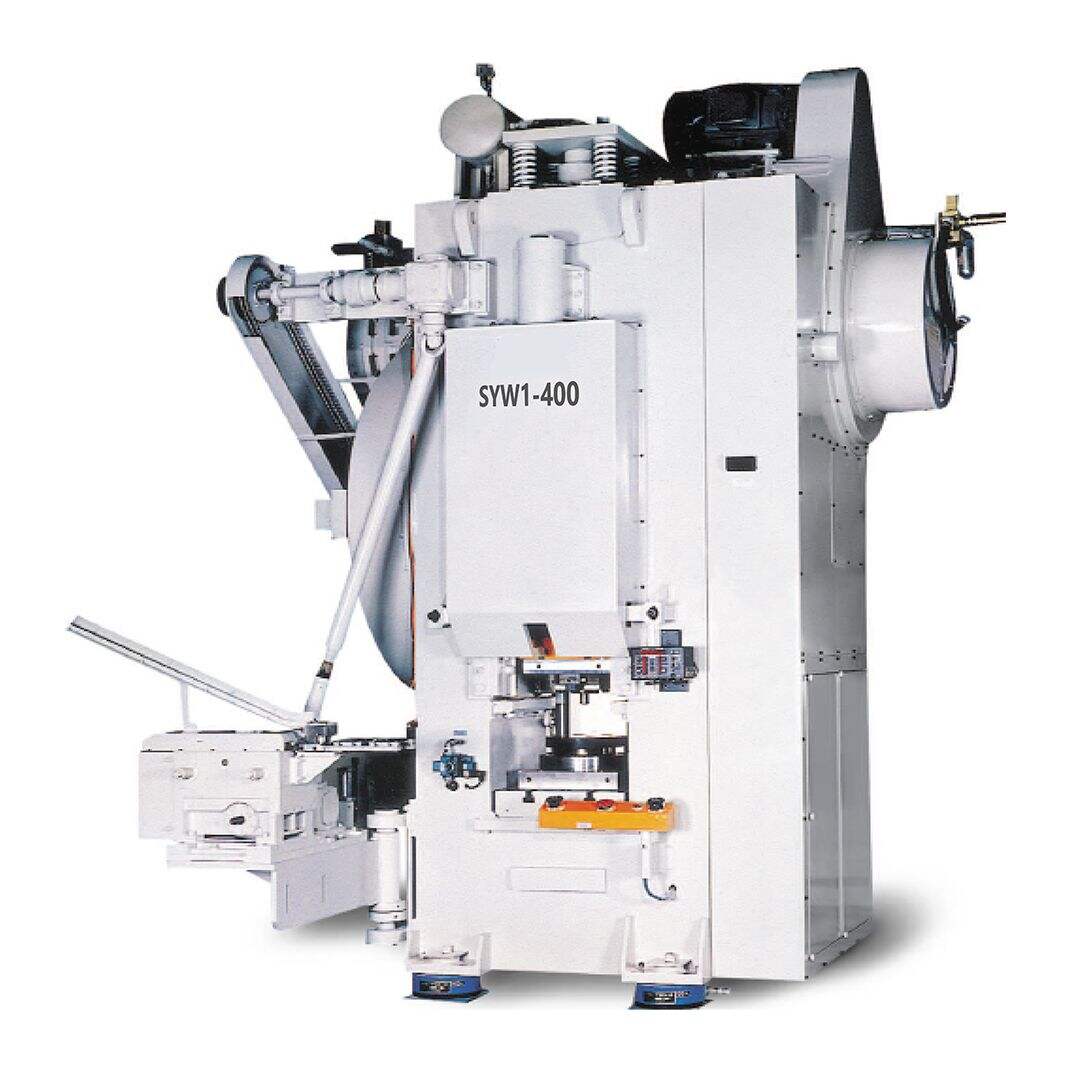

Well then, if a metal working company wants to level up, then it best invests in superior despoilers and feeders. Solid machines have huge implications on how well the business is being run. May 30, 2020 - PRLog — Liao provides despoilers and feeders with the highest level of efficiency and accuracy They are constructed to accommodate numerous dimensions and densities of supplies which makes them perfect for any kind of metal functioning company. When a company selects high-quality machines, they can revolutionize the way in which they get work done.

Thankfully, as time has gone by newer despoilers and feeders have become a lot better. With new technologies they certainly are much better and more efficient than ever before. This makes them even more efficient at their jobs than the older machines. And when these machines work together, you have a quick and effective production line. It is very much better for metal working work. With despoilers and feeders from Liao, the time required for efficient metal working operations is significantly reduced and helps in successful completion of the operation.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our Decoilers and feeders offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.

Our dedication to innovation, improvement and continuous reliability of merchandise and services is a constant. Our Lihao group is very skilled while offering cutting-edge solutions. We have been the real no. 1 selection for stamping automation. We place the higher value client satisfaction, providing top-quality equipment and exemplary services everytime.

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.