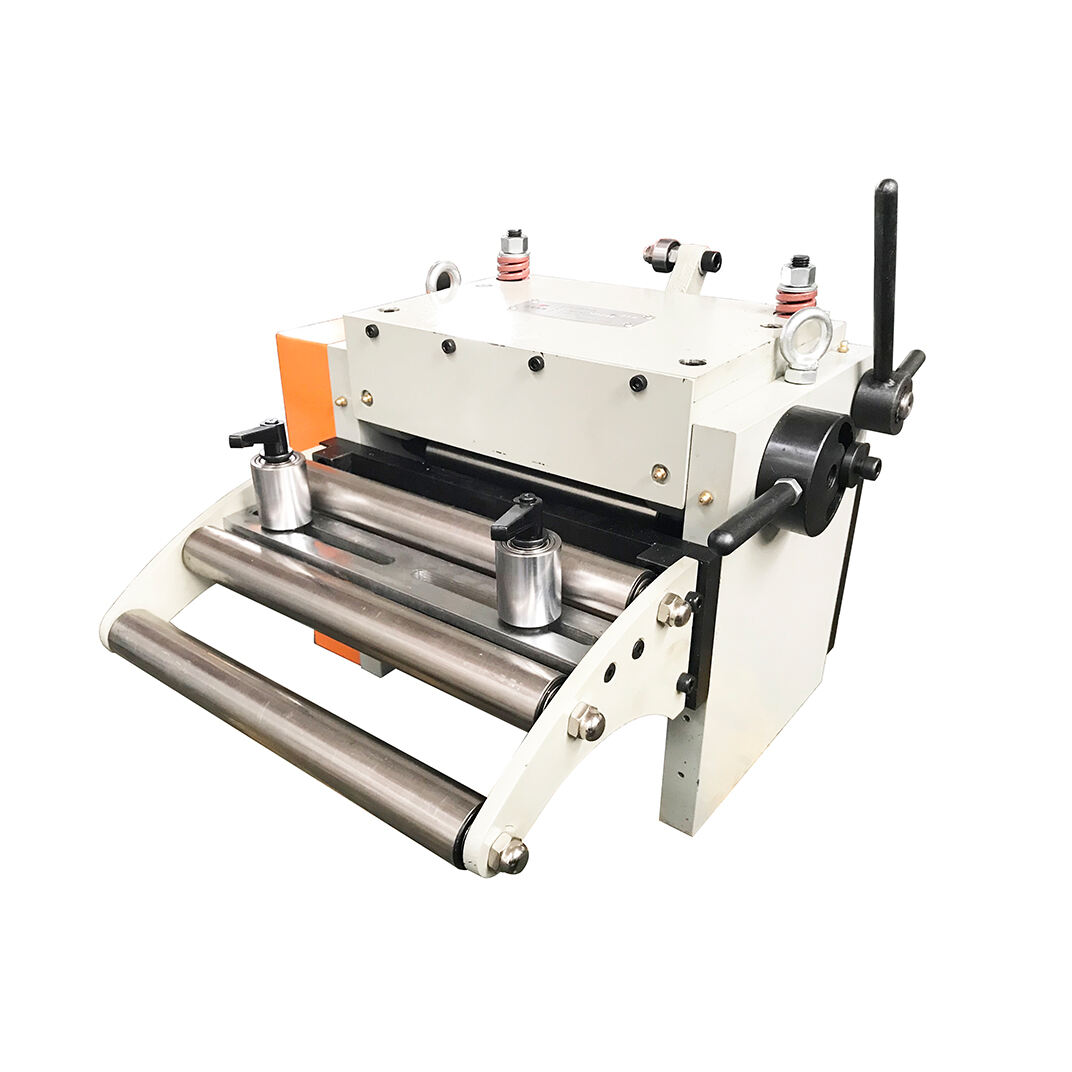

We at Lihao take immense pride in our precision engineering that is able to mold metal into exciting and innovative creations. One of the processes we use to make many metal products is called metal stamping. These include things such as car parts that keep cars running around the roads or products we purchase for use in our homes. We produce high quality products that are within exact specifications due to the accuracy of our metal stamping process. It's this attention to detail that distinguishes us.

We manufacture superior products in an expeditious manner using our high-end stamping technology. It is this technology that enables us to manufacture parts and products with unparalleled precision at scale. This becomes especially handy when we produce larger amounts of the goods. This not only allows us to produce items in bulk but also reduces the costs of our customers. We want to serve the needs of our customers better by providing top-quality items for a better price.

Our capabilities in tool and die allow us to make even the most detailed and intricate designs precisely, without any hassle. Tool and die is a step that plays a key role in the metal stamping process. They enable us to slice, mold and craft material in numerous sizes and shapes that allow our customers peculiar requirements. We use computer-aided design (CAD) technology to plan all aspects of our designs, in order to assure everything works as expected before we start the stamping process. Once our designs are complete, we create the tool and die to realize them. This integration of technology with craftsmanship ensures that we continue to create amazing products.

Our versatility of metal stamping is useful in wide range of applications. We manufacture bespoke metal products for several sectors, including automotive, aerospace, construction and many more. These industries have unique demands and our stamping technology enables us to produce parts and products with extremely tight tolerances. For creating fit parts, which often have exacting specifications concerning the size and contour, this precision is particularly important.

Metal stamping tools can improve our efficiency at lower costs but still uphold their quality nonetheless. Our stamping process is very automated which allows us to produce hundreds of products fast and efficiently. The labour cost for making the product goes down substantially, allowing us to pass on savings to our consumers by allowing us to sell at reduced price points. Our stamping tools also have the capability to produce parts very accurately in addition to cost savings. As a result, every product we manufacture is of uniform and good quality which helps us earn our customers trust.

Our dedication to innovation, reliability and constant improvement of services and goods are an ongoing procedure. Our Lihao team is extremely experienced and delivers cutting-edge technology. We are the first selection automation of. We place lots of focus on customer satisfaction by consistently supplying top quality and services.

We have been specialists in the design and engineering of durable tooling that minimizes setup adjustments and production that is scrap is reduces. Our metal stamping tool and die are able to deliver training that is global commissioning that ensures seamless integration and optimized performance globally. With in-house manufacturing plus quality parts that are spare we guarantee minimal interruptions plus the productivity this is certainly highest. As a ISO9001:2000 that is certified plus EU CE we abide by the high quality standards being highest.

Lihao Machine offers tailored solutions and complete services to fulfill different customer. We offering integrated services that encompass design, manufacturing and sales. Our committed R&D team will provide your with personalized alternatives and technical discussion guaranteeing each solution is perfectly customized to satisfy your own needs.

Lihao machine has been a frontrunner in the marketplace for more than 26 years. It is a reliable supplier on the domestic plus international markets. Our products are widely found in various industries worldwide. We provide our customers worldwide through additional than 20 offices around Asia and an indian subsidiary. We offer tailored solutions across various industries many thanks your extensive technology capabilities.