What Are Pneumatic Feeders?

Pneumatic feeders are the most essential equipment within any factory. Their basic duty is to quickly and smoothly, shift materials from one machine or work station into another so that there remains a continuous flow of production. This is pragmatic; in industries there are only so many things that can be done to cars or other manufactured products. Factories can also make items more quickly and keep a higher quality by using pneumatic feeder.

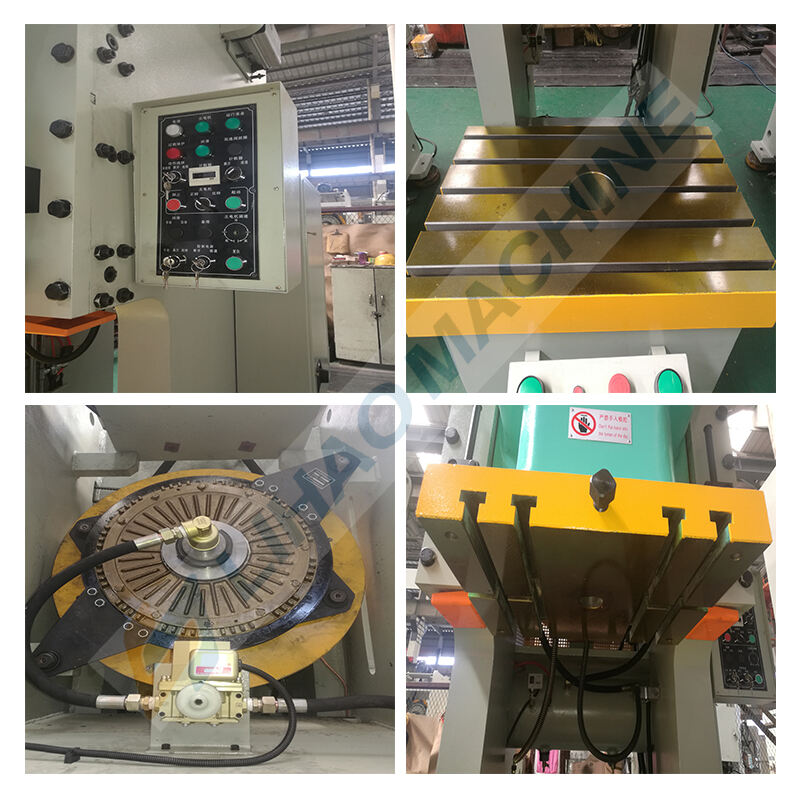

In function, the solution feeds much like a robot. It gently nudges stuff down the line of production step by careful hand-off. Using this method of shifting material is far superior to having a person move the same thing as it gives room for less error due to machine contribution. A Lihao pneumatic feeder as well as roll feeder machine helps to keep the work area clean and tidy, as well as error reduction from the part defective due to handling by human.

The Lihao pneumatic feeders and sheet metal feeder are obviously used for the air or gas compression and why we can say that these kind of feeders have many advantages over it than other ones in the factories. For one thing, they work orders of magnitude faster than humans do. This allows for faster delivery of goods without any time frame issues being handled. The second reason is that they are super accurate, so the printer will be able to keep a continuous stream of materials in one spot without having to stop or make errors. Factories are then able to work 24/7 in continuous operation. Fast and quick items are usually better quality it in time.

Mesh feeders can save factories a great deal of money because they cut down the amount of work that has to be done manually. This way labor is not needed, and workers can devote their full time to the assignments they got. These tasks can be quality control activities and other corrective measures in production. The less time workers have to spend moving materials, the more energy they can put into jobs that help your company grow and strive.

Additionally, pneumatic feeders and decoiler straightener feeder also are an important way to help prevent manufacturing errors from occurring. Machines are typically less error-prone than humans, if they do fine. As a result, less issues of jamming material, and missplaced materials. In order to establish a more dependable production, factories can utilize pneumatic feeders that help in making the work-flow smooth.

A second major importance of pneumatic feeders is that they can accommodate a wide variety of materials. This flexibility means that the servo feeder machine can adapt automated systems to every conceivable product. Where the configurable part type comes into play is that it can be adjusted to fit multiple different casting molds, thus reducing waste and increasing versatility which in turn shortens production time as well as increases final product quality.

When it comes to manufacturing quality products (sheet metal or plastic parts, for instance), excellent equipment is paramount. Numerous individuals will most probably do a great deal of these measures directly on the production floor with pneumatic feeders erected. This can greatly accelerate the manufacturing process and allow workers to more easily stay on top of everything.

Lihao pneumatic feeders are particularly useful in being programmable to correctly load materials into machines. There is long-run benefit in this type of automation, as the same work process gets done precisely every time without any deviation. When in production, the important thing is to maintain consistency; and pneumatic feeders help do that. These feeders are also flexible in nature and they can process a wide variety of materials like thin sheets to thick plates.

This application is most beneficial for the handling of heavy products destined to be manufactured; even a small error in raw material feed on these applications can cause big problems. They can lift very heavy parts and they are design to perform fast while keeping the safety at some level. All in all, pneumatic feeders are essential to factories for improving production efficiency and quality. These speed, accuracy and reliability features contribute a lot to the success of manufacturing operations.

Lihao Machine provides tailored solutions also as a complete service meet up with the various needs of customers. You can expect integrated solutions which cover design, production and sales. Our R&committed D team provide you with customized choices and technical discussions making sure each option would be suited to your unique criteria.

Our dedication to reliability, innovation and continual improvement of your products and service is an ongoing procedure. Our Lihao team is extremely experienced while offering cutting-edge systems. We have been the top solution stamping automation. We place a whole large amount of focus on client satisfaction by consistently delivering the better products and services.

Our company is experts in the development and design of durable tooling that can help to attenuate setup adjustments too as reduces scrap production. Our Pneumatic feeder for press offering training that is worldwide commissioning, which ensures the performance which is highest and seamless integration around the world. With your very manufacturing that is own and high-quality spare parts service we guarantee minimal interruptions in addition to productivity that is highest. We are ISO9001:2000 accredited and EU CE certified.

Lihao machine has been a leader on the market since 1996. It had been a reliable supplier regarding the national and international markets. Our items are used throughout the selection of industries around the world. We offer our clients worldwide with more than 20 offices in China additionally the branch in India. Our robust technological capabilities enable customized solutions for a variety of industries.