A precision stamping die is a machine that is critically important in producing things. It’s great for making parts quickly and accurately. Let’s find out how this machine operates, and why it is helpful in so many different applications!

A high-precision stamping press is a machine which utilizes pressure to shape material. There is a lot of pushing on the parts to ensure that they are built right.” This machine is necessary because it helps to make things quicker, faster and better instead of doing it manually.

Companies can make more parts in less time with the help of precision stamping press. This enables them to make products more quickly and sell them to customers more quickly as well. It also helps to reduce manufacturing waste, which is nice for the environment. In general, the machine helps companies perform better.

Stamping press is constructed to produce parts with more precision. That is, the parts it produces are high quality and have no mistakes. This is significant as it contributes in the final products being safe and reliable for the customers. Companies can consistently produce high-quality parts with this machine.

The precision stamping press is widely used in various industries to produce a variety of products. The technology can produce parts for cars, airplanes, electronics and even household appliances. This machine is versatile as it can be converted to produce different shapes and sizes of parts. It’s also a valuable tool for many businesses.

There are several advantages when using precision stamping press technology. The upside of both is that it can allow a company to manufacture components quickly and accurately, saving both time and money. Another advantage is that it improves the quality of the products. Ultimately, by using this technology, companies become more successful.

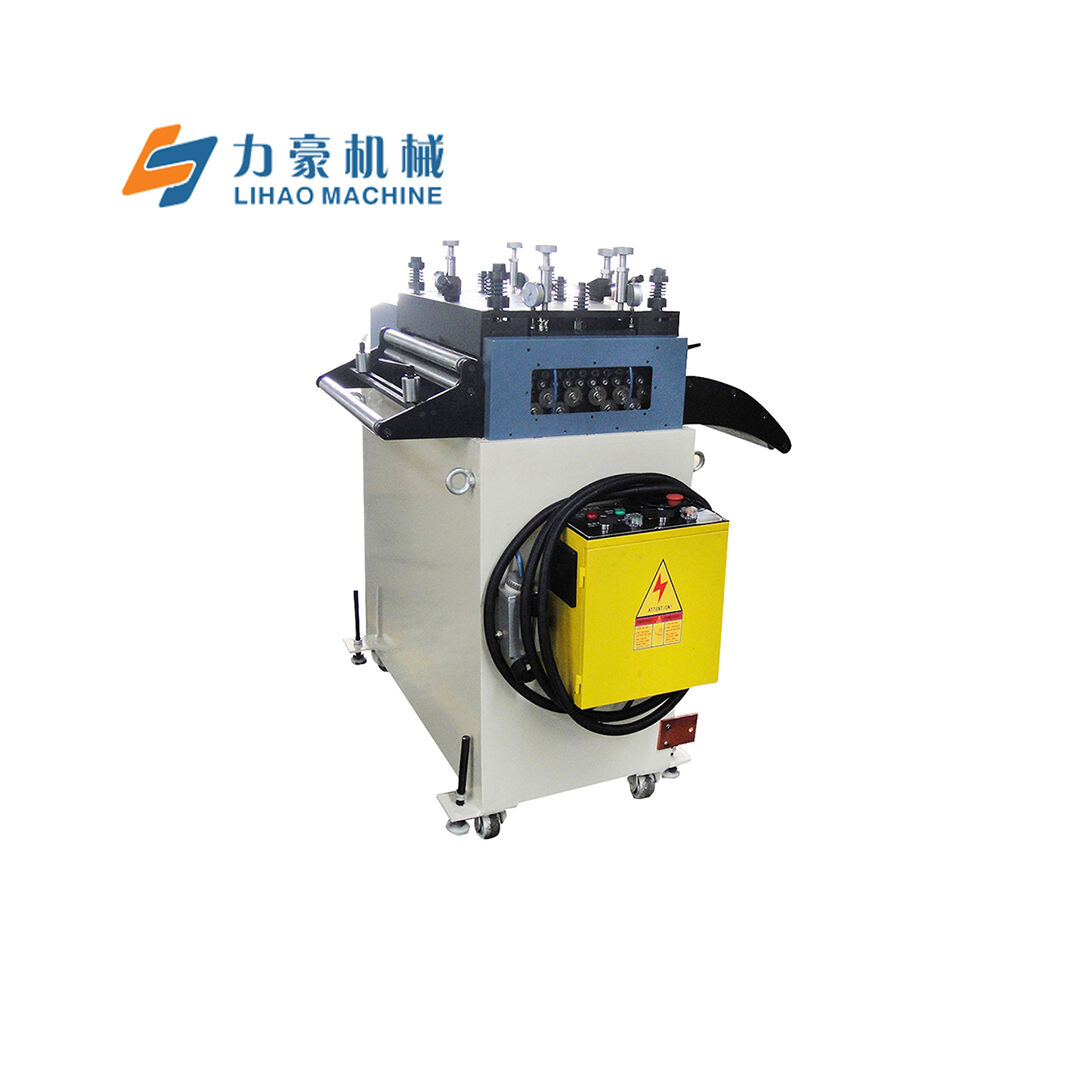

Our dedication to innovation, reliability and constant improvement of services and goods are an ongoing procedure. Our Lihao team is extremely experienced and delivers cutting-edge technology. We are the first selection automation of. We place lots of focus on customer satisfaction by consistently supplying top quality and services.

Lihao Machine offers tailored solutions comprehensive services to fulfill various customer. We offer integrated solutions which include design, production and product sales. Our R&D team is specialized in offering modification as well as technical discussion, making certain each solution is designed to meet your requirements.

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our precision stamping press offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.