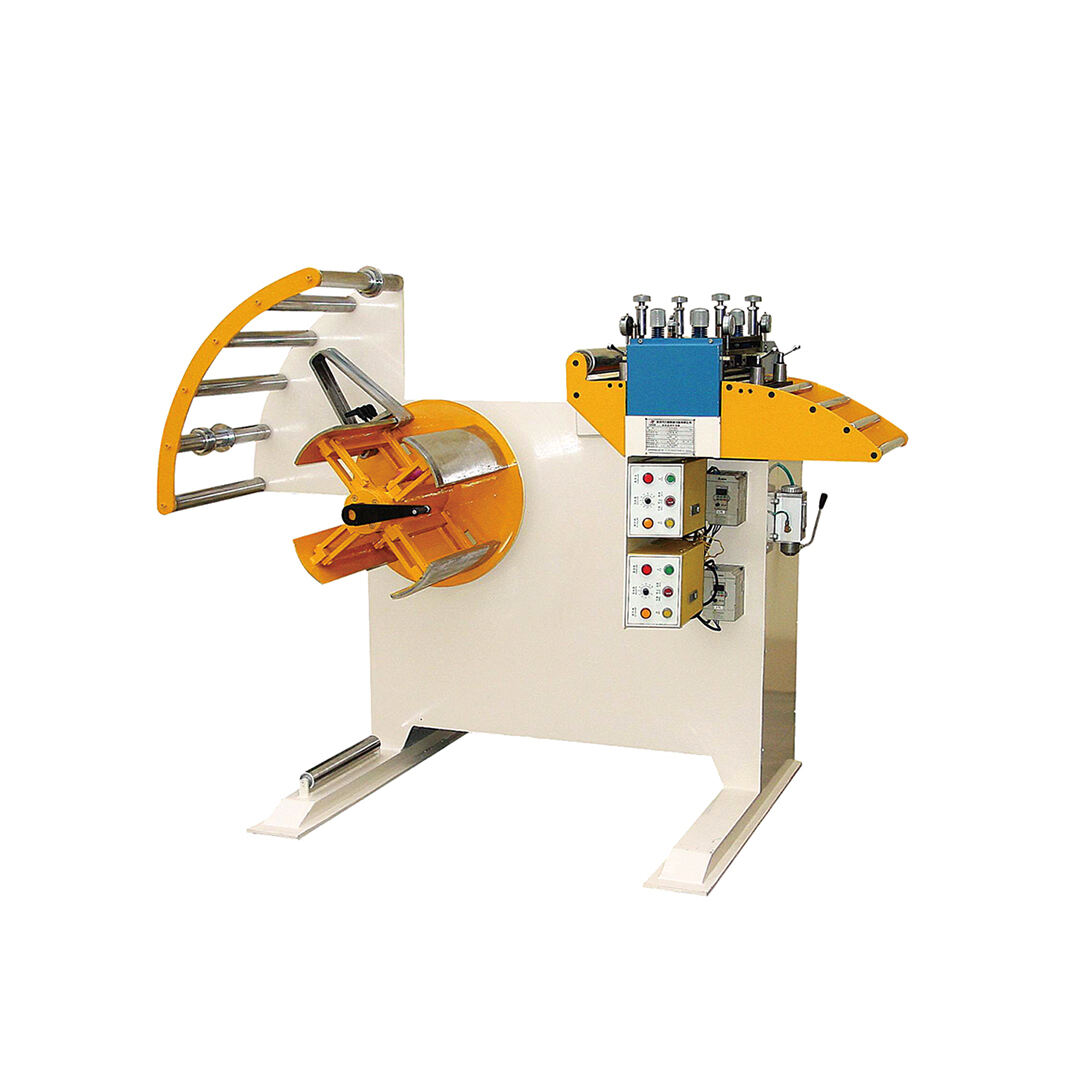

The work straightening machine is a special machine that allows you to work faster and more efficiently. They have essential components that make processes much neater, and not as annoying in production environments. Manufacturing work: The machines are very important to many businesses that need to make lots of things — and fast!, such as toys, clothes or even parts for cars. Press feeding lines are useful for manufacturers looking to comply with demand and satisfy the needs of their customers fast. These are improved points to improve our lives and work inside press feeding lines by Lihao. These machines are blessing in disguise, as they work at a fast pace. press feeding line are fast, so they allow manufacturers to produce more products in a smaller amount of time. The other key thing is correct. These machines are built to be accurate, and accuracy encourages reduced pressure on the part of workers as they do not having to worry about doing things right. The auto loading function is a testament to one of the good qualities of presses that it can do its work itself, so the labor required for them is also low. The automation of this feature lets workers focus on more high-stakes matters than tedious manual work. It serves the basic need of everyone to everything faster and getting tired.

Businesses can now work faster and more efficiently ever before with automatic press feeding lines of Lihao. But these machines help make everything efficient and correct as reducing errors that can result by a tired or confuse person doing the work. Example, when workers come to work not focused they may end up making mistakes Servo coil Feeder result in waste or defect product. Press feeding lines also reduce wastage of material. Because of the assistance from computer technology, these machines are capable of producing designs that will take an inordinate length of time to be penned by hand. Businesses will be able to deliver their products much quicker as it results in happy customers and more sales.

There are a number of things one needs to consider while selecting the perfect press feeding line by Lihao for the purpose and ensure that it is most befitting. The first thing that you ought to do is understand your business and what purpose will the machine serves. In business, one size does not fit all, so it is essential to know what you need. You need also to think about the materials with which the machine will work. Material makes a difference: coil cutting machine are many things to look out for here, and the thickness and size of your material really do play a big part as not all machines can deal with every type of material. Also, your budget plays a major role in selecting the best press feeding line for your plant. Well you want to make sure that what you are getting for your money is a good value. Make sure to consider a robust machine that will not have type to fixed it more often and this will save you time and money.

Automation, as provided by press feeding technology is a way of life for many businesses that it serves. These are intelligent machines and they have a smart software integrated into them that can sense the thickness of materials. Once the thickness has been established, the machine can make adjustments, accordingly. This coil handling equipment prevents wastage of the sheets which are not used daily and their spoilage over time due to production. This also means this technology is silent and frees of pollution which brings workers in more healthy working conditions. Happier and more productive workers make everyone happier when the workplace is comfortable.

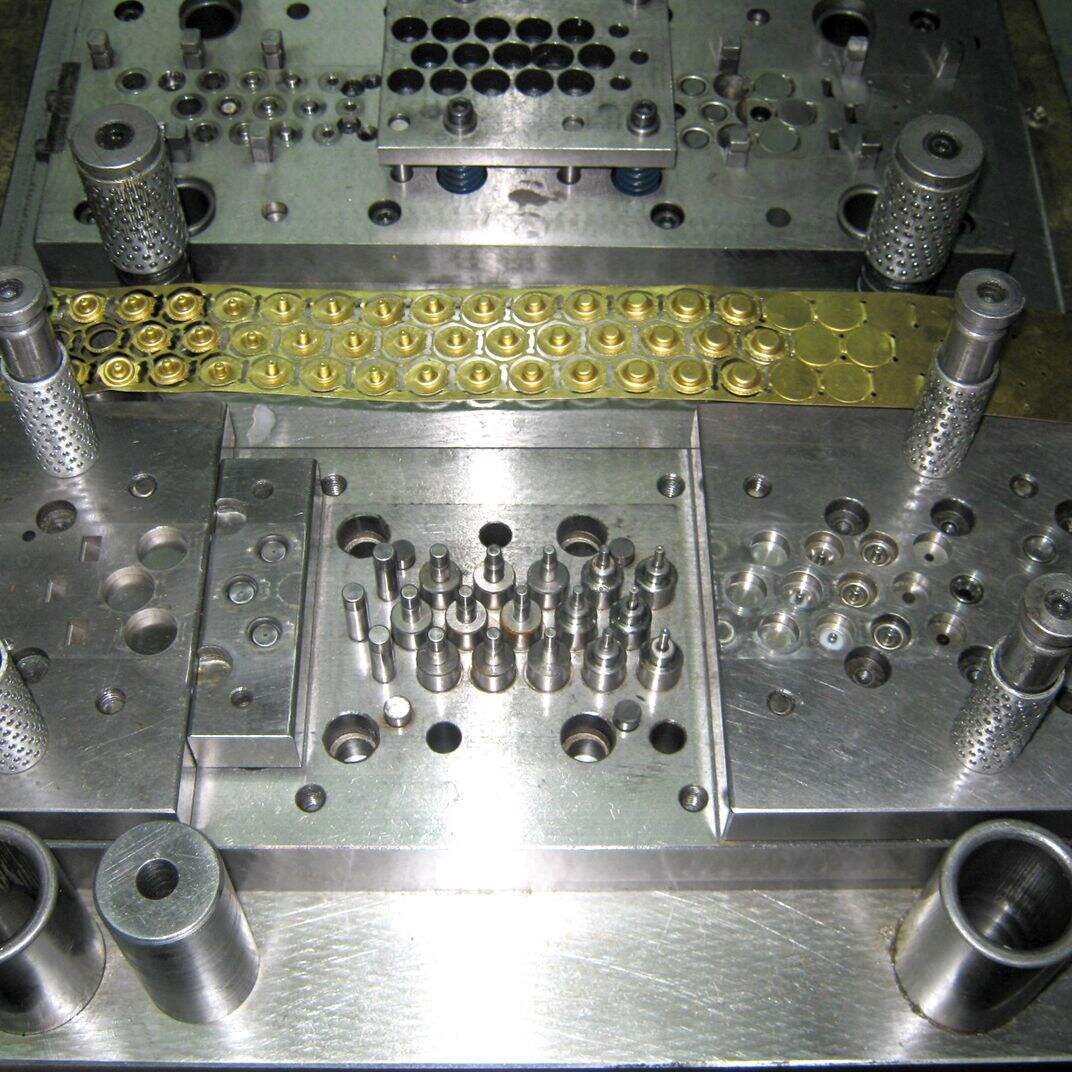

The use of high-quality press feeding systems is essential if a business requires well-designed products to be produced in little time. These systems are specifically designed not to stop mistakes but reduce them by avoiding waste. Reducing errors saves businesses money and resources which is always a good thing. If compound stamping companies are able to reduce these losses, they can make more by selling what they have but not having lost it all in the process. What this means consequently is that investing in a press feeding system could bode well for the business and its success in the long run.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our Press feeding lines offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.

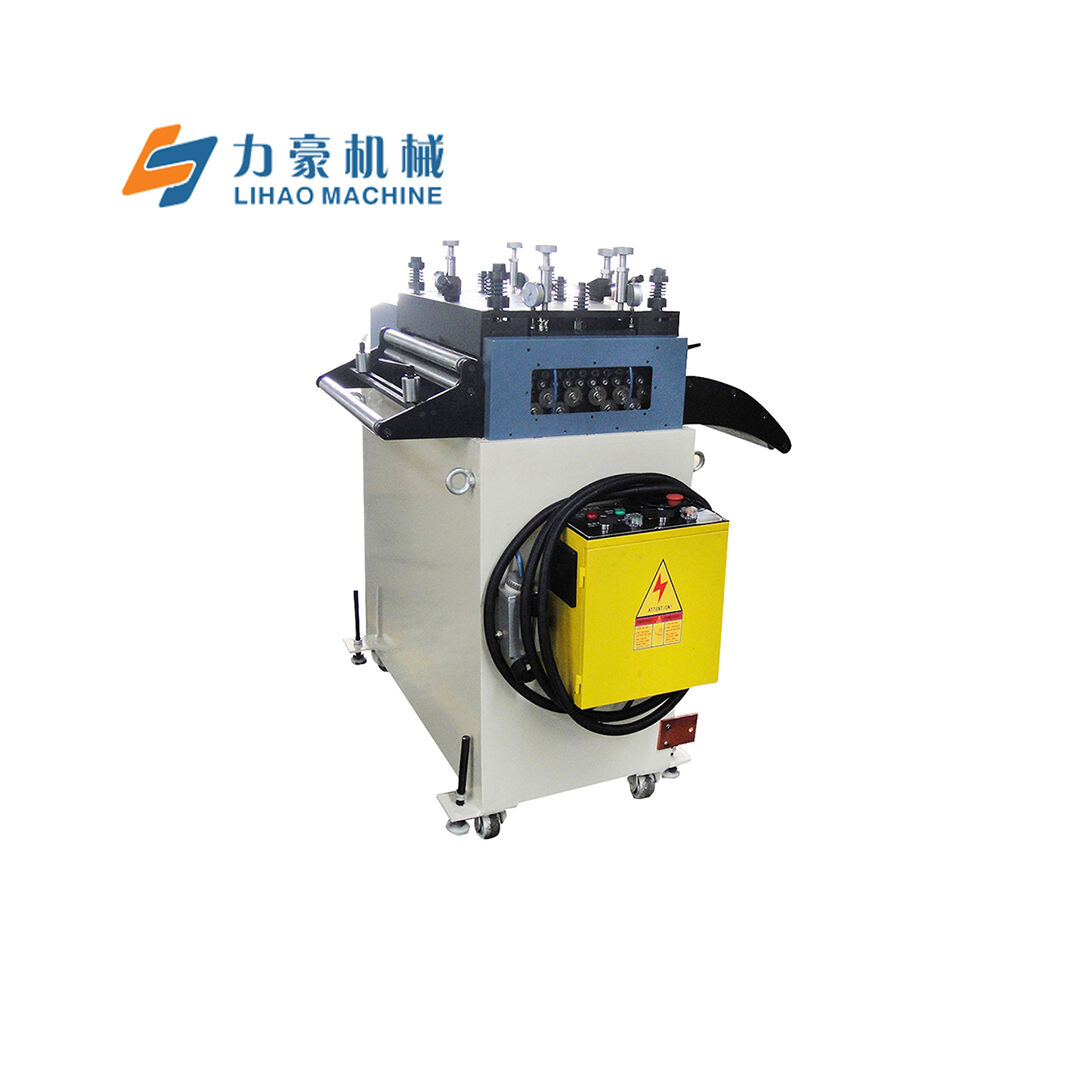

Our dedication to quality, reliability and continual improvement of products and service is an ongoing procedure. Our Lihao team is highly skilled and offers cutting-edge solutions. We are the true number one solution in stamping automation. We place great importance in ensuring consumer satisfaction by consistently supplying the quality highest products plus services.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.

Lihao Machine offers tailored solutions and complete services to fulfill different customer. We offering integrated services that encompass design, manufacturing and sales. Our committed R&D team will provide your with personalized alternatives and technical discussion guaranteeing each solution is perfectly customized to satisfy your own needs.