Progressive die making is a vital method for the production of parts and products. It is useful for producing many different components simultaneously and in a single operation. It saves time and money and results in quality products.

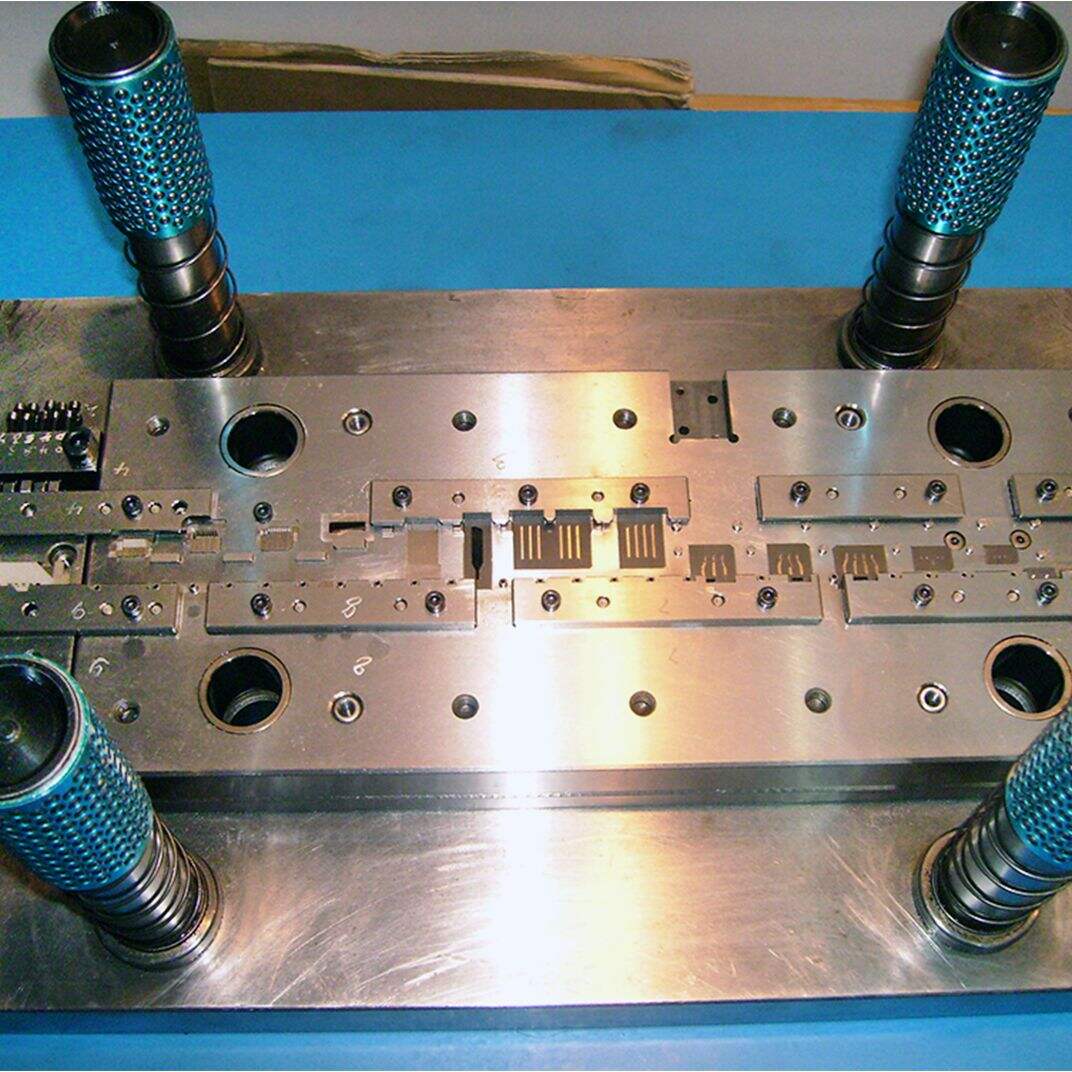

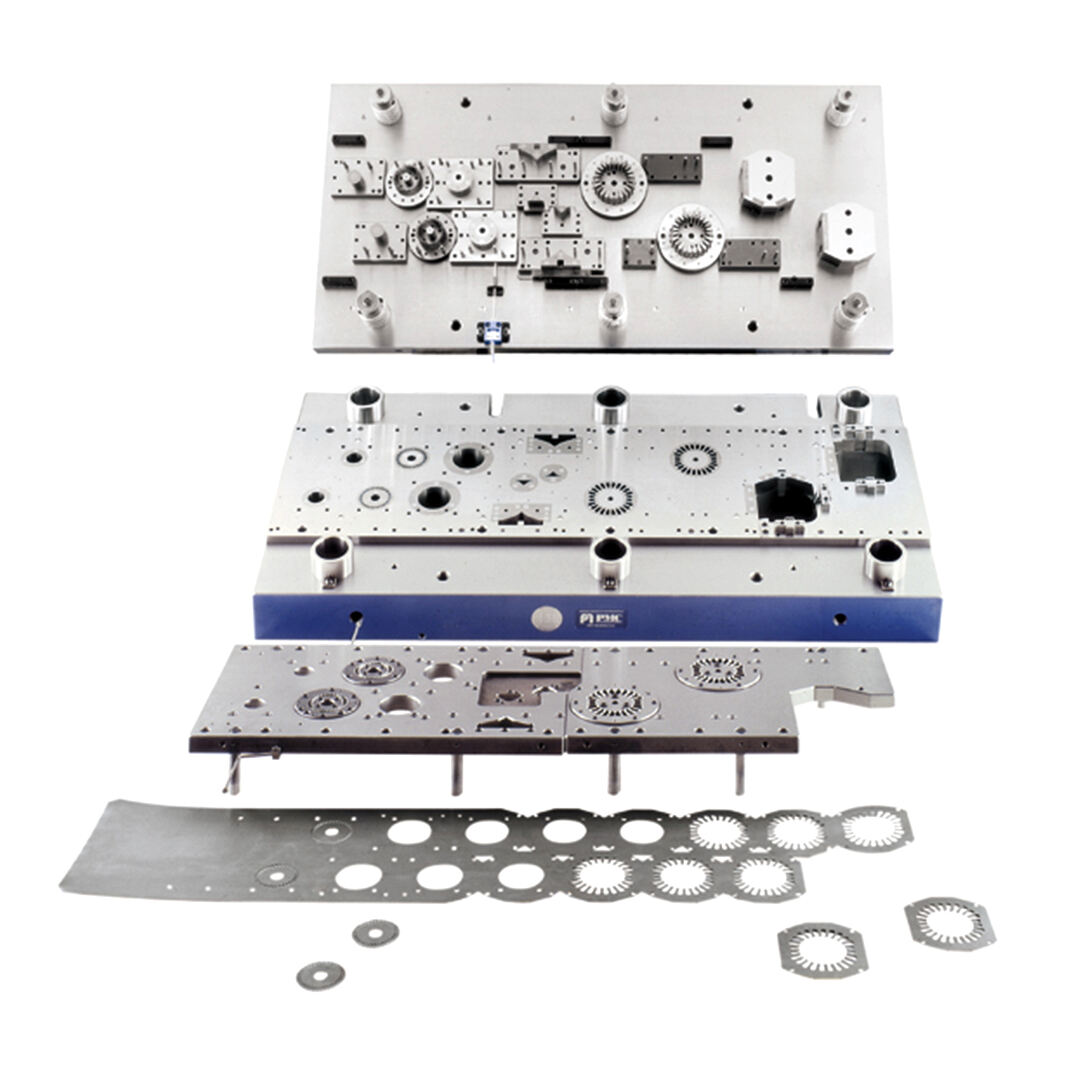

Tool the special tool used in the 3 in 1 servo feeder process is called a die. This is a fairly complex die. Each part section cuts, shapes or forms a specific portion of the article. As the metal strip progresses through the die, the individual sections cooperate to form the end product.

It is one of the essential needs in this fast world to utilize progressive die technology. Manufacturers can also make more accurate, intricate parts more rapidly and with fewer errors using ever more sophisticated machines and computers. This cuts down on waste, and enhances the quality overall.

Progressive dies manufacturing methods enable manufactures to produce a large amount of parts in a short time. This is useful for companies that have tight deadlines to meet and must fill orders as quickly as possible. With this technology, manufactures can work faster and with better quality and also keep their quality high.

The progress of precision manufacturing technology in FDS has made great progress with large size. With the aid of CAD (computer-aided design) software and sophisticated machining technique, manufacturers are capable of making complex designs with extreme precision. So much detail goes into the making of each, that it meets strict quality standards.

Maximizing the effectiveness of sophisticated progressive die designs is essential to competing in todays marketplace. In these cases, by buying the best equipment and obtaining the newest technologies, manufacturing units can scale up their production while cutting down on manufacturing expenses. This allows them to provide good prices to their clients while maintaining good quality.