Progressive die technology is just a neat way to make metal objects. It makes them fast and it makes them accurate. So how does it all work?

It's like a metal cookie cutter. 4. It slices metal sheets into various shapes. And in goes the metal, out comes parts. Each section is built up step by step as it passes through the machine. This speeds up the production of many pieces at once.

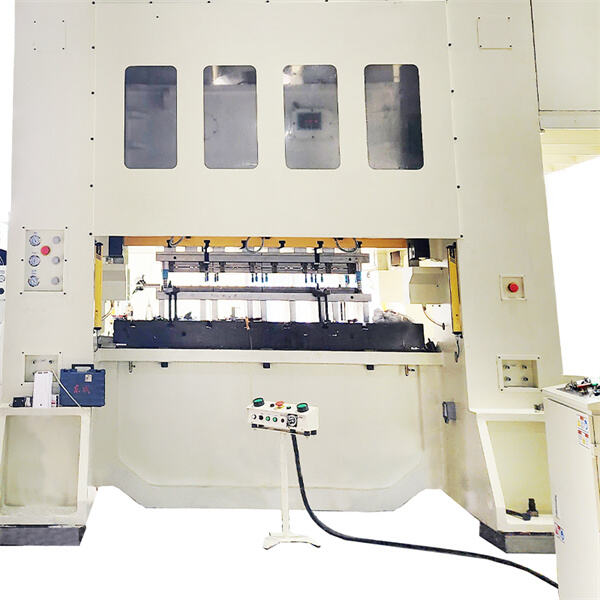

Stamping is when the machine puts that metal down to make shapes. Better still is if you can do everything in one fell swoop, which is possible with Coil Feed Line stamping. The metal travels the machine and is stamped into various shapes. That saves time, and the parts fit better.

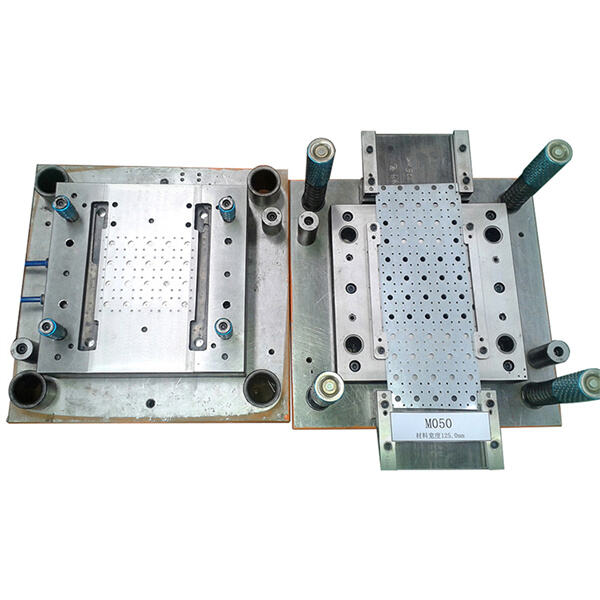

Progressive die is good for those stuffs with plenty of details. It can cut and bend and shape metal with great precision. It is crucial for creating objects like car parts and electronics. The parts are strong and fit together very well from the progressive die.

All kinds of different shapes and sizes can be produced in progressive die. It can create simple things like brackets or complex parts like gears. There are a million ways to design it. Then the engineers can get creative and design all kinds of unique looking parts with progressive die technology.

Progressive die will be better in the future. Machines will be quicker and more efficient. Stronger parts will be produced from new materials. The technology will continue to evolve to make manufacturing easier and less costly.

Lihao Machine is a huge business is leading the industry because 1996. It is only a trusted supplier both the national and international markets. Our products are trusted in lots of industries throughout the world. All over the globe with over twenty offices in China and an overseas branch in Asia We provide our customers. We offer tailored solutions throughout various industries with this robust technological capabilities.

Lihao Machine provides tailored solutions in addition to a complete service meet various needs of clients. We offer integrated services that encompass design, manufacturing and sales. Our R&committed D team supply you with customized options and technical conversations, ensuring that every solution is suited to your unique requirements.

Our dedication to innovation, reliability and constant improvement of services and goods are an ongoing procedure. Our Lihao team is extremely experienced and delivers cutting-edge technology. We are the first selection automation of. We place lots of focus on customer satisfaction by consistently supplying top quality and services.

We are specialists into the design and development of strong tooling, that can help to reduce setup adjustments as well as reduces scrap production. Our progressive die offer global training and commissioning, ensuring performance that is maximum integration worldwide this is certainly seamless. In-house manufacturing and top-quality spare parts provider we could guarantee downtime which is maximum productivity that is minimum. Certified and ISO9001:2000 and EU CE We uphold the standards that are standard are greatest.