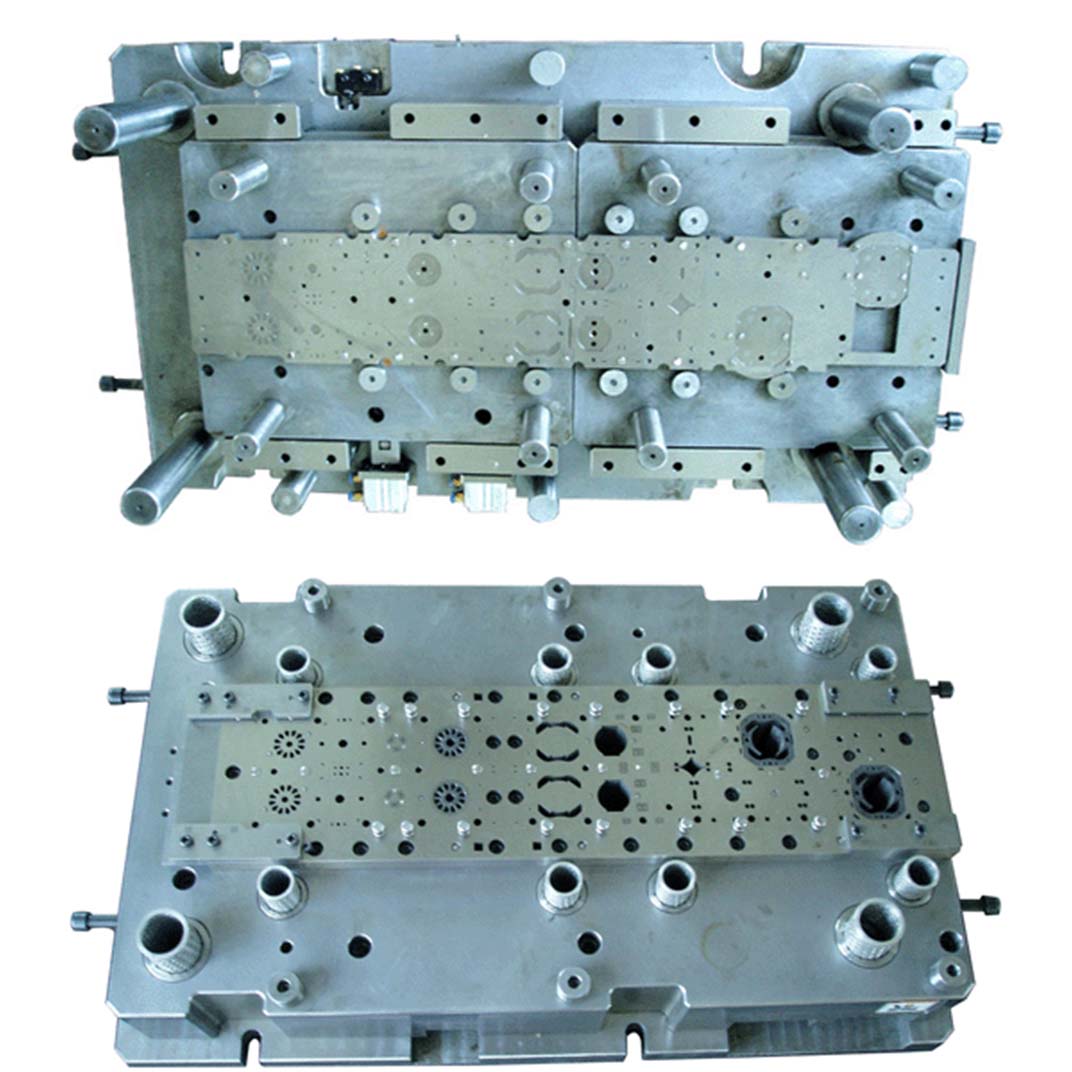

Have you ever seen a mold? Mold is a unique detail that alters plastic or metal materials into specified shapes. This allows for the easy and fast creation of thousands of identical objects —perfect for manufacturing. One of the main advantages of a progressive mold is that it saves time. Traditionally manufacturing different products requires changing molds, this can be a time-consuming process slow down production. However, with only one single progressive mold can Lihao coil handling equipment then produce countless of items without stopping to change molds. They are able to manufacture more items in a shorter period of time, which is very beneficial for the economy.

Progressive molds are nothing new, only the technology behind them continues to improve. Manufacturers are constantly looking for new ways to enhance the process, making it faster than before. They currently apply computer-aided design (CAD) to mold layout, as an example. They can draw up 3D models of the molds and see how their products are going to turn up before Lihao coil handling equipment have even been realized. They use this to figure out anything that is going on early and easy.

Progressive molds are nothing new, only the technology behind them continues to improve. Manufacturers are constantly looking for new ways to enhance the process, making it faster than before. They currently apply computer-aided design (CAD) to mold layout, as an example. They can draw up 3D models of the molds and see how their products are going to turn up before Lihao coil handling equipment have even been realized. They use this to figure out anything that is going on early and easy.

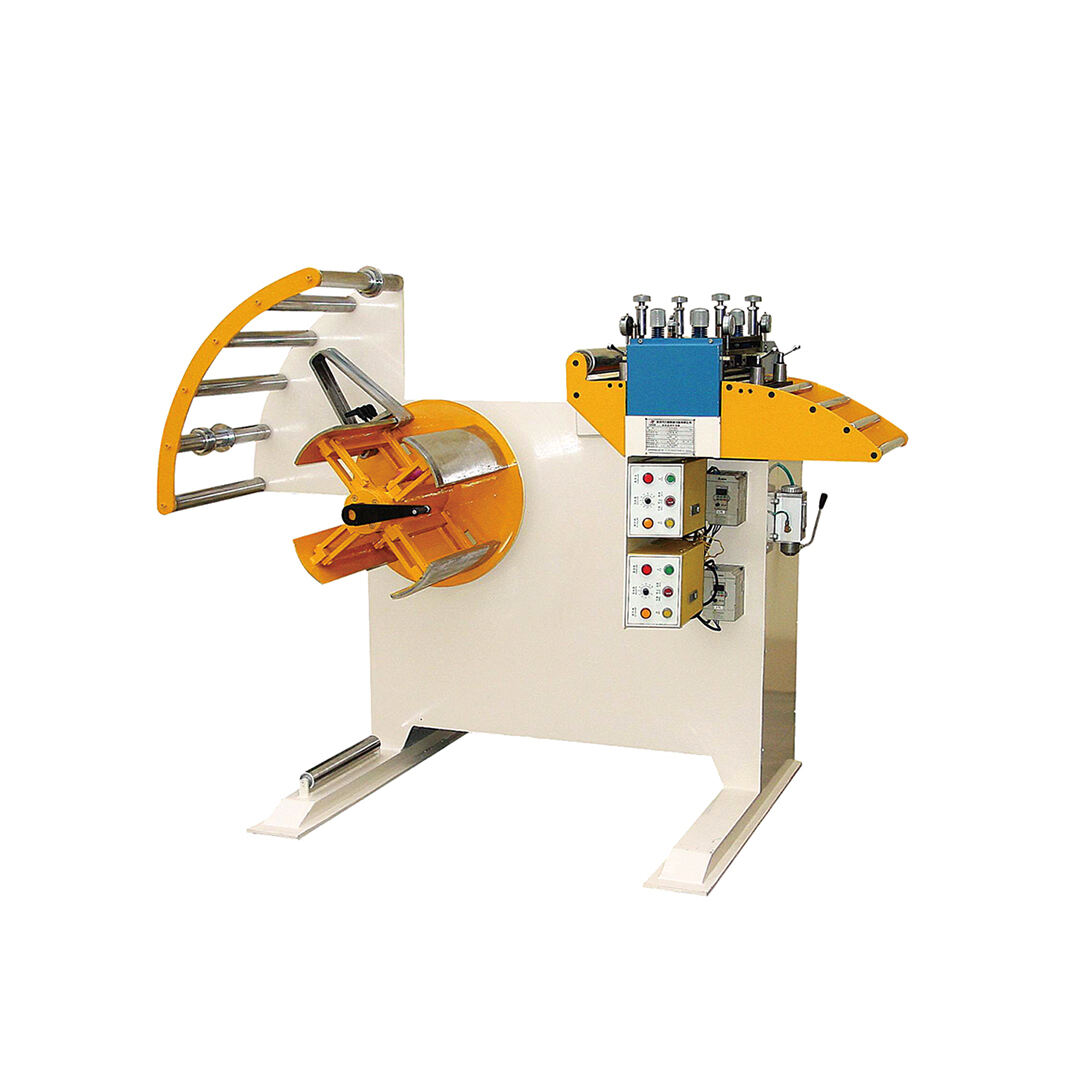

Progressive molds save money for the manufacturing companies. Having less production time and lesser material used in making Lihao roll feeder machine will lead to a more efficient production for manufacturers. When manufacturers able to produce higher quantity in short time scale, manufacturer can sell more item and therefore earn for money. This is good for their business but also good for the customers, often meaning they can get products at far better prices.

Lihao is devoted to providing our customers well guaranteed products and the best price/performance ratio through careful operation. We are strong believers in Lihao Coil feeder and its capacity to change the manufacturing industry. That is why we spend heavily in cutting-edge technology and gear, to be able to offer our customers always the best built product that they can buy.

Lihao Machine happens to be the marketplace leader for 26 ages. It's the trusted provider both domestic and international markets. Our items are extensively utilized in many industries throughout the world. We offer our customers throughout the global world with nearly 20 offices in China and an indian branch. We offer tailored systems around many industries using our advanced technological capabilities.

Our dedication to quality, reliability and continual improvement of our services plus products is an ongoing procedure. Our Lihao team is highly trained and certainly will provide cutting-edge solutions. Our company is the true number one option for stamping automation. We place a high benefits customer satisfaction, offering top-quality products and superior services consistently.

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our Progressive mold offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.

Lihao Machine offers tailored solutions and complete services to fulfill different customer. We offering integrated services that encompass design, manufacturing and sales. Our committed R&D team will provide your with personalized alternatives and technical discussion guaranteeing each solution is perfectly customized to satisfy your own needs.