Progressive stamping is a super cool way to produce a lot of parts quickly. It works almost like magic! You may be wondering to yourself how that all happens, and good, let’s find out.

When we need to produce many parts at once, 3 in 1 servo feeder is the way to go. It’s having a lot of machines working together to make parts rapidly, and efficiently. By using progressive stamping, we can produce several thousand parts quickly. This is a key tool that enables us to meet our customers needs and do it quickly and happier!

One of the coolest things about Coil Feed Line is that it allows us to make parts stupid fast. Instead of making individual parts one at a time, let’s make lots of parts all at once. This is time and money we would rather not spend, and that’s the best for our business. And now, because we can manufacture pieces so quickly, we can deliver them to our customers faster than ever. It's a win-win!

When it comes to parts, precision and accuracy are very important. We like it to be exactly the same for all the parts; that way everything works well together. Using progressive stamping, we can create parts extremely accurate. “Which means our shapes fit perfectly with each other!” she said, forgetting herself in excitement. Because we take care when we craft our parts, our peers can rely on the fact that the parts will work just as they should.

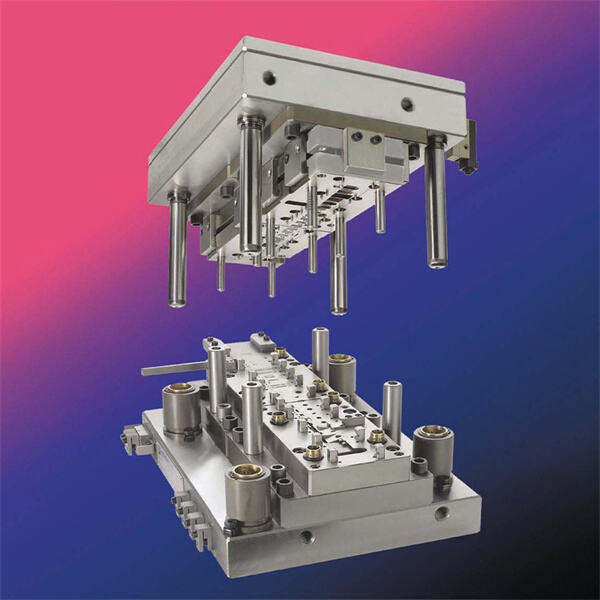

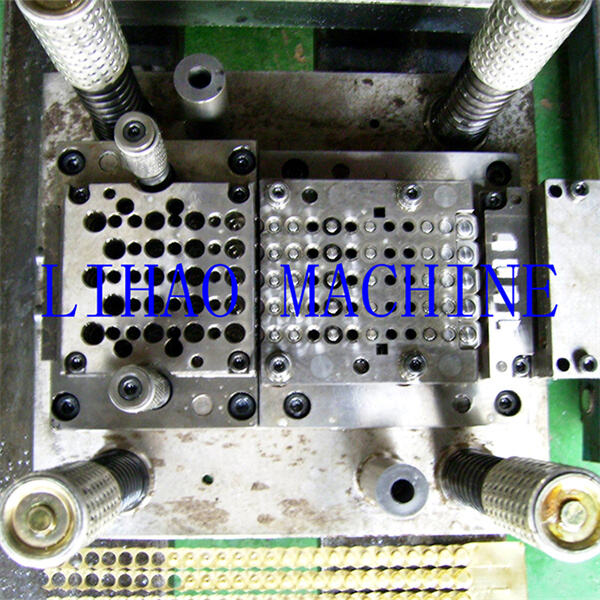

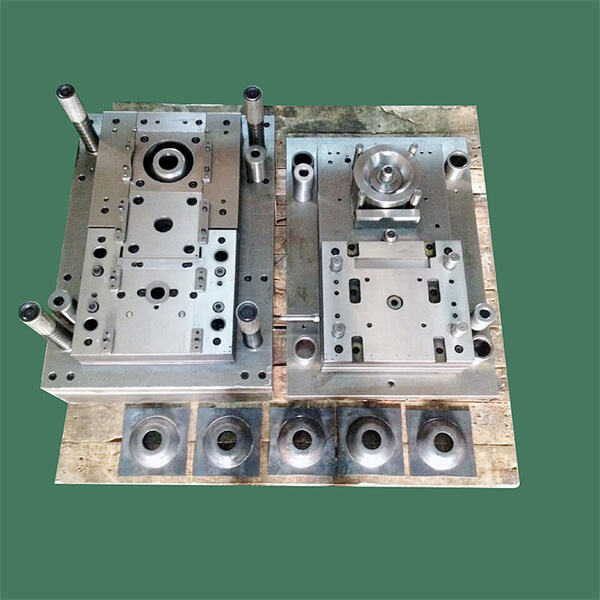

There’s some magical technology that progressive stamping uses. Our machines are like superheroes, fighting together to be fast at making parts. Each machine has its own unique task, whether that’s cutting, bending or shaping the metal. They all harmonize together seamlessly to make great parts. This new technology allows us to make better, faster parts than we ever could have in the past. Read: It’s robots on our side!

Progressive stamping is not just fast and efficient at making large volumes of parts, it can make really complicated parts. Because we have such fancy machines, we can build parts with all sorts of interesting shapes and angles. That means that we can take difficult projects and be able to produce parts that other companies may not be able to. When it comes to progressive stamping, there is nothing we can't make. Our clients trust that we can do the toughest jobs with ease.

Our dedication to quality, improvement and continuous reliability of products and service is a constant. Our Lihao team is extremely skilled and offers cutting-edge systems. Our company is the stamping possibility first automation. We have been focused on client satisfaction, providing top-quality products outstanding service.

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our progressive stamping offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.

Lihao Machine provides tailored solutions comprehensive service meet up with the diverse needs of customers. Offering a selection of products, including 3 in 1 feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we offer incorporated services covering production design purchases, service plus trading. Our R&D team is dedicated to ensuring that the option is had by you of customizing your choices and technical discussions making sure that every solution is perfectly tailored to your requirements.