The servo feeder system is the brain of the machines. They assist in performing controlled, careful movements of materials by machines. You can find them on factory floors and assembly lines to ensure everything is working as it should. Servo Feeder Mechanism picture this — a robotic arm, picking up small bits and putting 'em in the perfect spot, time after time!

In making things, accuracy is important. Think about making a toy car. Put the wheels on in a different place every time and the car does not work right. Servo feeder systems helps ensure every part is very precisely placed, so that every toy car that comes out of factory is exactly as it should be.”

In a productive line, employing a servo feeder mechanism offers many of the advantages. ‘There are several benefits to doing this – it reduces errors, saves time and streamlines work. In other words, factories can churn out more products in less time, and that’s good news for everyone! And because everything is so precise, there’s less waste, which is better for the environment as well.

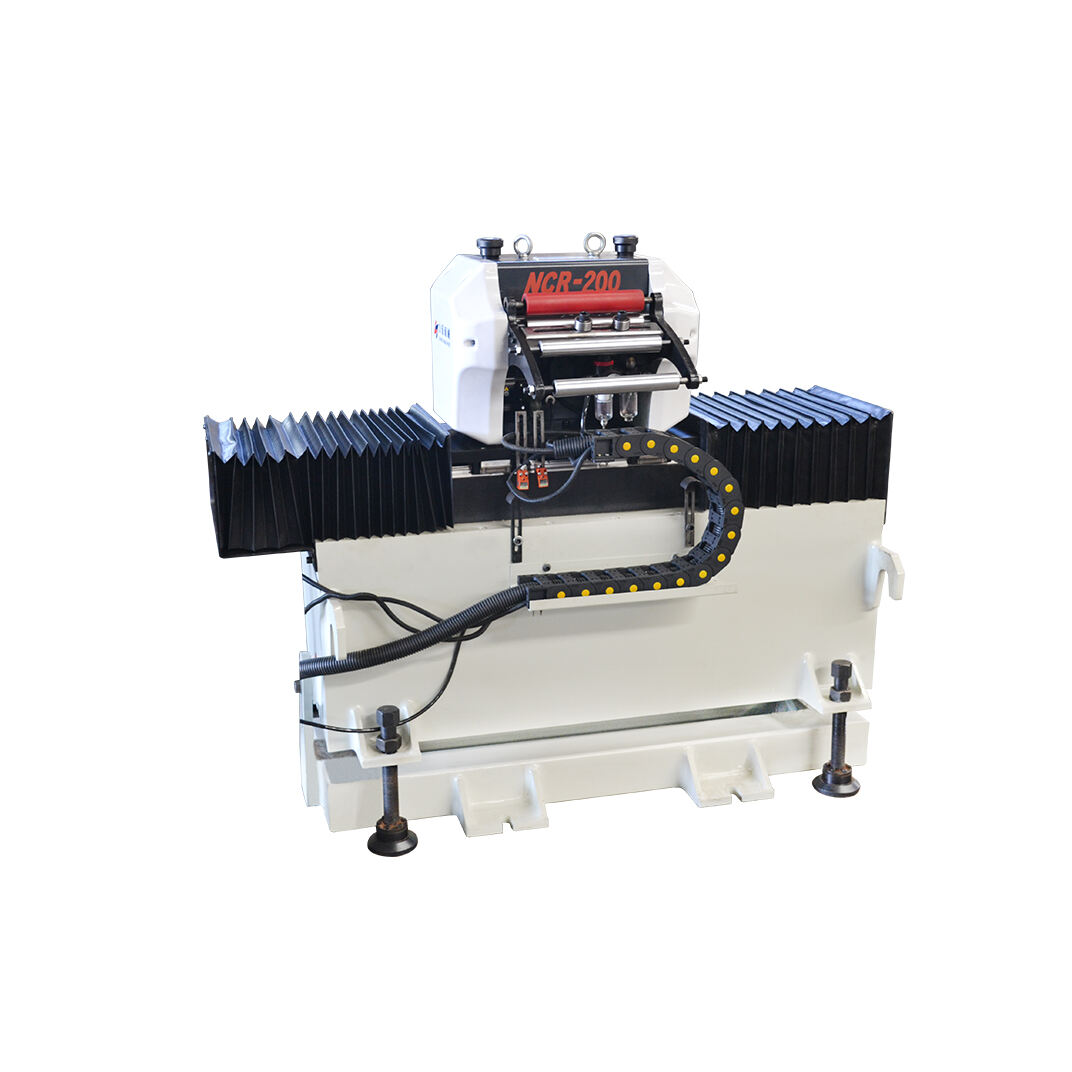

How servo feeders function – a little more exciting! They manipulate materials by controlling how they move, using special sensors and computer programs. These sensors send signals to the mechanism, instructing it where to place each part. It’s like a digital dance that takes place again and again, ensuring that everything is in place just right.

Think about a huge factory full of machines that work together to manufacture goods. Now consider this, each machine operates at its peak performance as a result of the mechanism in the servo feeder. That means the entire process works without a hitch. Servo feeder mechanisms by making things more efficient, result in factories being able to manufacture more goods in less time and everybody on the planet is happy.

Lihao Machine has been a company that has been leading the field going back 26 years. It is an established supplier the domestic and international markets. Our items are used in various industries worldwide. And over twenty offices in China and an India branch overseas serve customers globally. Our advanced technology capabilities let us offering tailored solutions diverse industries.

we are focused on innovation and dependability, continuously updating our products and services. Our skilled Lihao team provides cutting-edge solutions helping to make us the most preferred option automation equipment found in stamping. We value customer and tend to be committed to providing top-quality equipment and exemplary solutions on a regular basis.

Our company is specialists in the creation plus engineering of high-quality tooling which minimizes setup adjustments and scrap production that is decreases. Our servo feeder mechanism provide worldwide training and commissioning that ensures performance that is maximum seamless integration around the planet. With manufacturing in-house and top quality spare parts help we guarantee minimal downtime and productivity that is high. We are ISO9001:2000 certified and CE which was EU approved.

Lihao Machine provides tailored solutions and comprehensive service meet up utilizing the varied needs of our customers. You can expect integrated services that include design, production and sales. Our R&committed D team give you with customized choices and technical discussions, ensuring that every option would be tailored with their certain needs.