Servo mechanical presses are neat machines that can do a variety of different tasks. They are used to produce things like car parts and appliances and even toys. Let’s find out about how Lihao’s servo mechanical press operates and how it makes things faster and better.

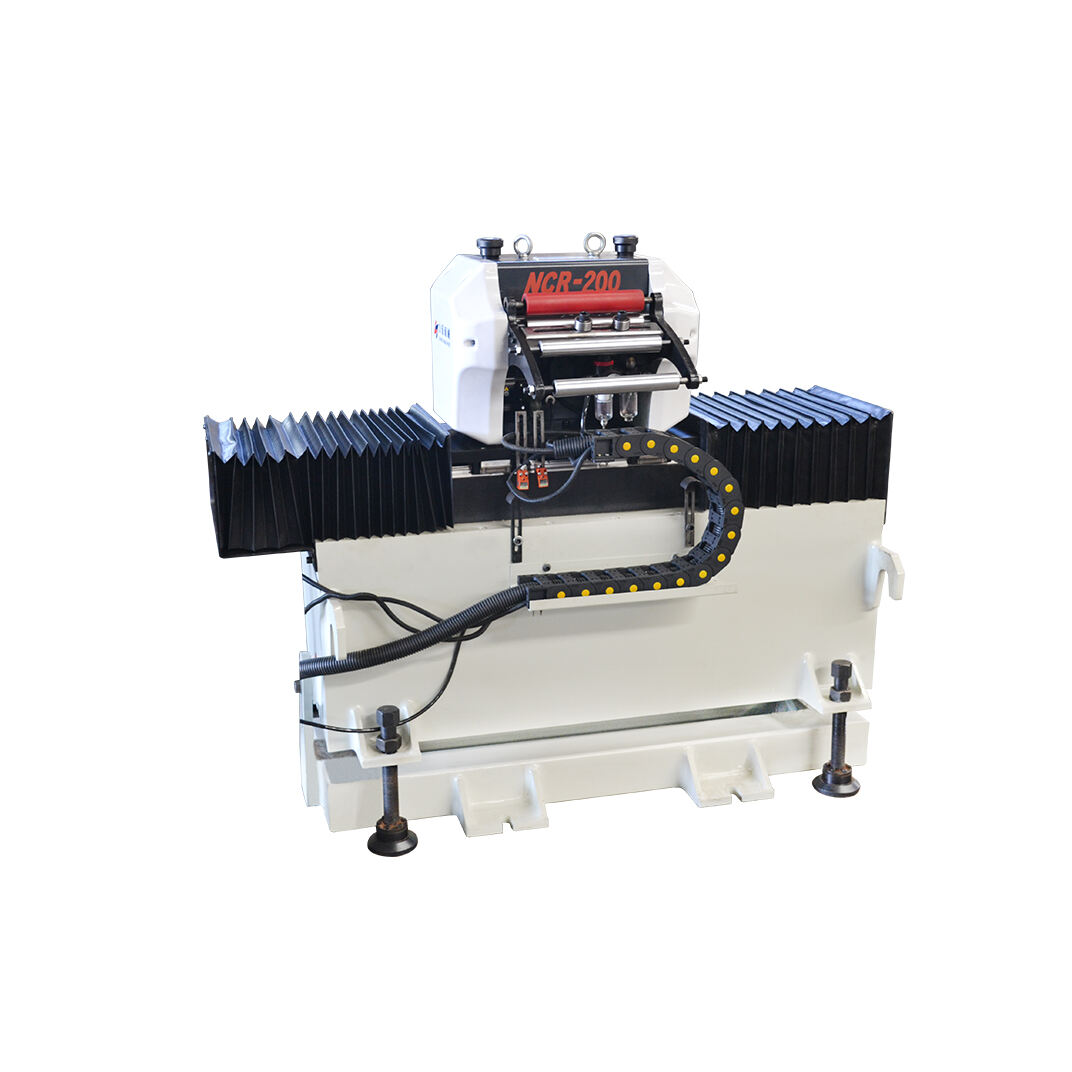

A 3 in 1 servo feeder is a unique kind of machinery and it can stamp and form metal. It has a motor to regulate its motions. This helps it perform very precise cuts and bends in the metal. That servo motor is the brain for the press, for what it’s all going to be doing. This gives the press a combination of flexibility and versatility to produce a wide variety of parts.

So how does the servo mechanical press perform so well? The latter lets the press traverse the part fast and true, so you can make lots of the same part. The servo motor can be used to program so that the same cut is repeated over and over, ensuring that each is like the last. This reduces waste and is good for production efficiency.

A really nice thing about servo control is that small changes can be made. This allows the press to adjust and alternate its speed and force as necessary. This is crucial in fabricating parts that require varying degrees of pressure. With servo control, the press can change these parameters automatically and might not require assistance from an operator.

Lihao is continually doing to make its servo mechanical presses better, stronger and more efficient. A new trend is to put sensors on the press to watch it while that press is working. These sensors can identify any problems and adjust to keep the press running smoothly. This helps prevent outages and costly repairs, ensuring the press stays in good running condition.