The term “servo stamping press” — what on earth is that? But fear not — we’re here to help you make sense of it all! Servo stamping press technology is a pretty cool way to produce things from metal. Let’s play with those machines and discover how they work and why they matter in the production of things.

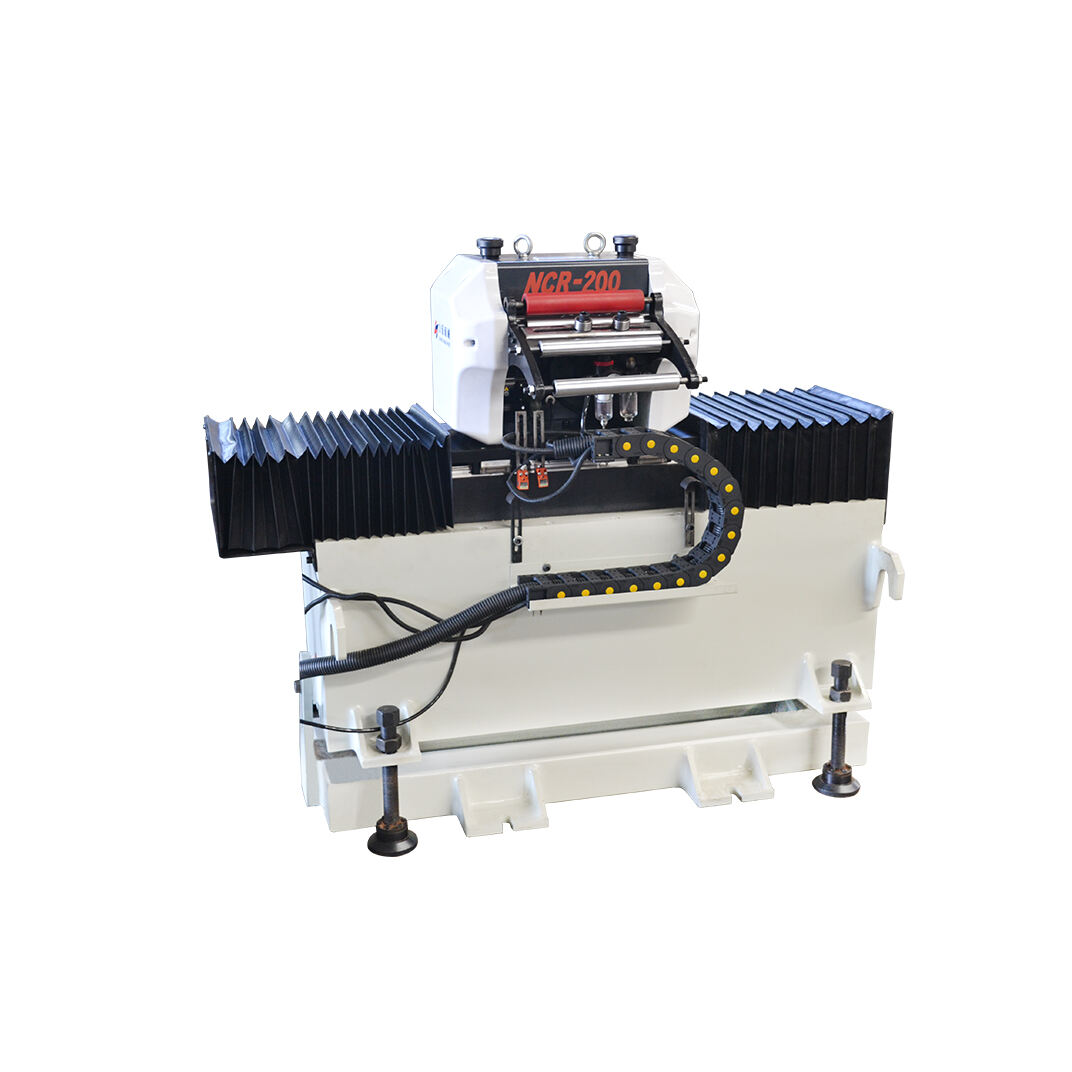

A servo stamping press is a large piece of equipment that has power to stamp or cut metal into different shapes. It has a special kind of motor, called a servo motor, that makes it easy for the robot to move quickly and precisely. It’s a technology that helps factories make metal parts that are the right size and shape.

What 3 in 1 servo feederes do best A serving stamping press is what it’s best value is — it stamps metal parts very accurately. The result is that everything just… works, because the parts they make fit together seamlessly.

Servo stamping presses also have a high productive rate. That’s because they can work lots of metal much more quickly. This is useful for businesses that must create many products in a hurry. Servo vs Mechanical – Manufacturers often get the best of all worlds using servo stamping presses.

The process of production of servo stamping press Product by servo stamping presses has various advantages. A big advantage is that they can produce complex metal parts that other machines cannot. That is because they are capable of making very fine shapes with fine manners of control.

Yet another kind of the same tool is that they’re able to work with different types of metal. Steel, aluminum, copper—you name it, these machines can stamp and cut through just about any kind of metal you throw at them. It’s what makes them quite popular among manufacturers from various sectors.

There are a lot of places where servo stamping presses can be used. They are common in sectors like cars, airplanes and electronics, where operations make parts for cars and computers. Such machines can also be used to produce household items, such as appliances and furniture.