Sheet metal progressive die is a unique type of tool that allows the workers to bend, and cut and punch metal sheets. It is very important in many fields of work including your car, electronics, and buildings. It has made it easier, faster and accurate to create metal designs as compared to the days of yore where you would have needed a sheet metal feeder. This saves time and energy while keeping everything done properly. So, we will find out some more about this tool and the various benefits it can provide to people in different fields of work.

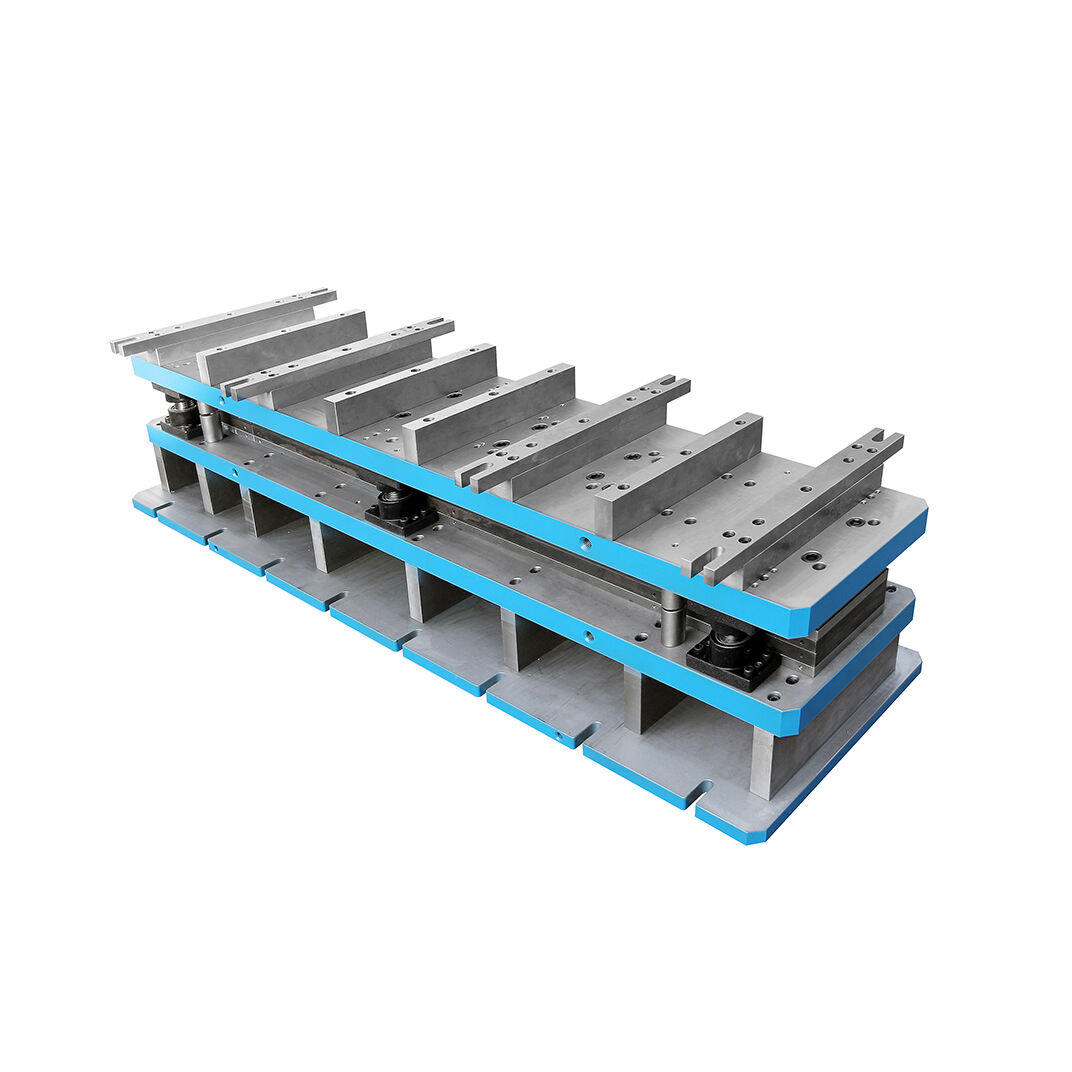

Like other types of die —whether for molding, stamping, or pressing— the sheet metal progressive die is a crucial part in revealing how metal workpieces are formed. Initially, employees design the metal pieces on a computer via specific design software. It also uses software that enables them to create a 3D model of what they are trying to make. When the design is finished and looking good, it is passed onto heading / sheet metal progressive die. This die is composed of multiple elements referred to as stations. With specific duties at each station, the whole process becomes streamlined.

With a sheet metal progressive die, workers can design and shape metal designs with meticulous detail. Designs created on the computer get turned into a tool, meticulously crafted to produce exactly what you want. Every station has a perfect job to do, so that when all the pieces come together at the end, everything looks just right and has every detail it should have. This tool is able to create a variety of designs that all serve unique purposes, for example, shapes, stamps or other types of unique forms that are often needed in the manufacturing process.

Punching: Sheet Metal Progressive Die is ideal for producing high volumes of parts. This equipment is used to rapidly cut, carve and punch shape of metallic sheets. Since each station does its work differently, this overall speeds up the time to make a product. The tool is also highly efficient, so it does not require much assistance from workers. That translates to less error in production and better quality of each product batch.

The greatest advantage of the sheet metal progressive die is that it ensures uniform quality in each part manufactured. The reason that the tool will create identical features is because whatever uniqueness there is, per part, must be in the process and so every part looks and works exactly the same. This ensures of a high quality products desired by customers. This also means better accuracy of the tool which in turn helps avoid errors thus needing lesser rework or correcting of mistakes. It helps the manufacturers to save a lot of costs.

Sheet metal progressive die brings a whole new level of excitement in sheet metal stamping making complex designs and different shapes. With its accuracy and efficiency, this tool allows manufacturers to produce complex designs that were so difficult years back or virtually impossible. It has revolutionized the manufacturing industry by enabling speedy, accurate production of complex geometrical shapes that can enable innovative products.

Lihao is a top Manufacturer of sheet metal progressive die. They manufacture high-end tools that aid workers in becoming more efficient and productive at this task. Tools that Lihao uses are specifically focused on improving metal-making process, produce intricate creations and work fast for mass-manufacturing scale. Their offerings are popular because they provide consistency and cost-savings applying to numerous sectors.

Lihao machine has been a frontrunner in the marketplace for more than 26 years. It is a reliable supplier on the domestic plus international markets. Our products are widely found in various industries worldwide. We provide our customers worldwide through additional than 20 offices around Asia and an indian subsidiary. We offer tailored solutions across various industries many thanks your extensive technology capabilities.

Lihao Machine provides tailored solutions in addition to a complete service meet up with the varied needs of your customers. Offering a number of products like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, plus punch machines, we offer complete service that cover manufacturing, design, sales, service, and trading. Our R&devoted D team customization options and technical discussions, ensuring that every product is customized to fulfill your individual needs.

We are aimed at innovation and dependability and will also be constantly expanding our services and items. Our knowledgeable Lihao team has the capacity to provide cutting-edge solutions, creating us the preferred choice equipment for stamping automation. We have been devoted to customer satisfaction, providing top-quality equipment excellent provider consistently.

We have been specialists in the design and engineering of durable tooling that minimizes setup adjustments and production that is scrap is reduces. Our sheet metal progressive die are able to deliver training that is global commissioning that ensures seamless integration and optimized performance globally. With in-house manufacturing plus quality parts that are spare we guarantee minimal interruptions plus the productivity this is certainly highest. As a ISO9001:2000 that is certified plus EU CE we abide by the high quality standards being highest.