Ever wondered about how we come up with the metal components that we see day-to-day? It’s really interesting! For example, these metal parts can be made by using sheet metal feeders. These machines are unique, as they utilize a mold to press flat metal sheets into all various forms and sizes. You can visualize it as creating cookies with a cookie cutter. Although instead of cookies, we receive metal chunks that could be utilized in numerous products and machines!

The traditional way sheet metal stamping has been revolutionized the process of manufacturing. Historically, metal needed to be carved and shaped manually. It was extremely gradual, laborious, and expensive. However, sheet metal stamping machines usher in a new era of quicker production and less carbon emissions. This indicates that we conserve time and money while creating metal components, benefiting companies and also consumers!

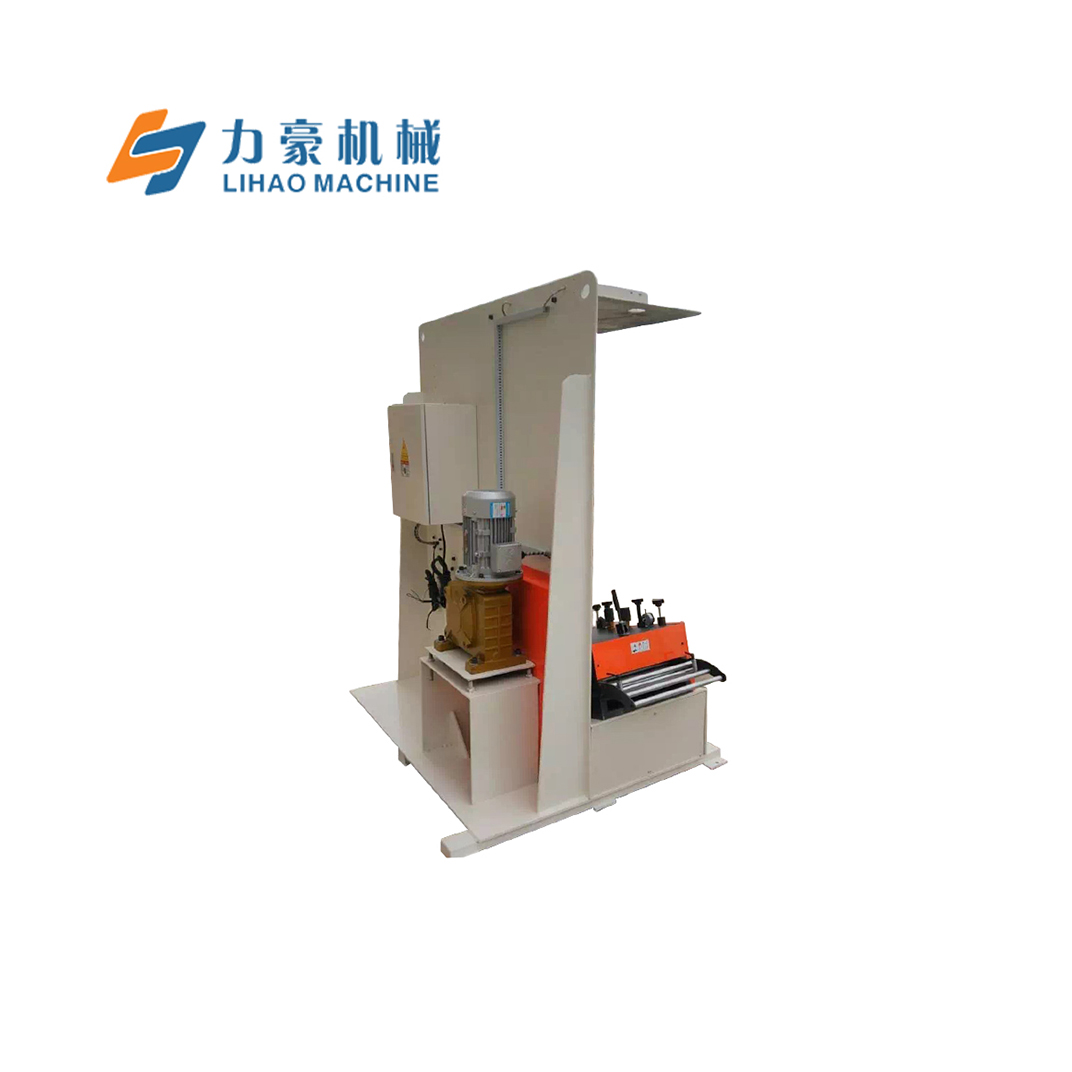

We are proud to implement by the technology Lihao is using whereby the sheet metal stamping machines. We have high-end machines that can manufacture parts to extremely high tolerances. Simply put, every part we create is identical to the molds that make it. This means that every piece matches and slots into where it is needed. This is hugely important when building things that need to integrate!

Even better, our machines handle multiple metal types. We may use metals such as Aluminum, Stainless Steel and Copper. This allows for a variety of parts to be produced for a variety of industries ranging from cars and electronics all the way to appliances. Flexibility: The experience to work with a variety of metals enables us to accommodate our customers needs.

With the rapid-fire pace of our current world, also known as the modern era, time is indeed money. Lihao sheet metal stamping machiens are specifically designed for high speed production where the nature of parts and its required cycle time defines it. High speed and effective part production, but no compromising on quality and accuracy. That means we can deliver the best parts — and our customers can rest assured they will have them at their disposal on time.

It is this capability that makes us take large orders in minutes, keep on time with our deliveries, and ensure that our customers stay a step higher than their competitors. This allows us to respond swiftly to changing needs, whether the customer requires more parts or a different kind of part. This is very important flexible in business!

We manufacture parts relatively quickly and efficiently at Lihao using automated stamp machines. This means it saves both our time and money as well as reduce the human error scope. This allows us to automate our process, providing parts with exceptional precision and quality output while also simplifying the entire manufacturing process.

And over 26 years experience in industry leadership, Lihao Machine is a supplier which was top the domestic and international markets. Our products is widely found in a wide range of. All over the world with nearly 20 offices across China because well as an overseas subsidiary India we provide our clients. We provide customized solutions in several industries, with your robust technological abilities.

We are aimed at innovation and dependability and will also be constantly expanding our services and items. Our knowledgeable Lihao team has the capacity to provide cutting-edge solutions, creating us the preferred choice equipment for stamping automation. We have been devoted to customer satisfaction, providing top-quality equipment excellent provider consistently.

Lihao Machine provides tailored solutions comprehensive service meet up with the diverse needs of customers. Offering a selection of products, including 3 in 1 feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we offer incorporated services covering production design purchases, service plus trading. Our R&D team is dedicated to ensuring that the option is had by you of customizing your choices and technical discussions making sure that every solution is perfectly tailored to your requirements.

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our sheet metal stamping machine offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.