Have you ever wondered how factories cope with the difficulty of unwinding steel? These coils are big in mass as well as heavy, so unrolling them without breaking or hurting the coil is really tough. Now, this is where they start facing problems and the entire process slows down. Therefore a good quality steel coil slitting holds great significance. It eases the process and provides good results for the factory.

In the end, Lihao is a company dedicated to producing amazing machines. They possess a reliable steel uncoiler which aids factories to enhance their production. Used by East Coast supply companies, our Lihao steel uncoiler is built for the really complicated work and tasks inherently tough duty environment loading cycles. That means factories can trust this machine to perform chores and increase production for them.

Lihao steel uncoiling system for a factory to speed up their production without compromising on the quality. This machine automates the unwinding of steel coils which reduces the number of workers needed to enable everything else to work right. This not only helps in manufacturing the products at a faster pace, but also ensuring that orders are filled faster. It enables factories to best-achieve their objectives while satisfying the customers.

In Lihao steel uncoiling system there are some necessary safety configurations. Among them is a hold-down arm keeping the coil in place while it unravels. The purpose of which is to keep the coil from slipping and potentially injuring personnel. The machine also includes an emergency stop button that workers can use in case of trouble. This extra layer of safety makes sure that everyone works confidently and safely.

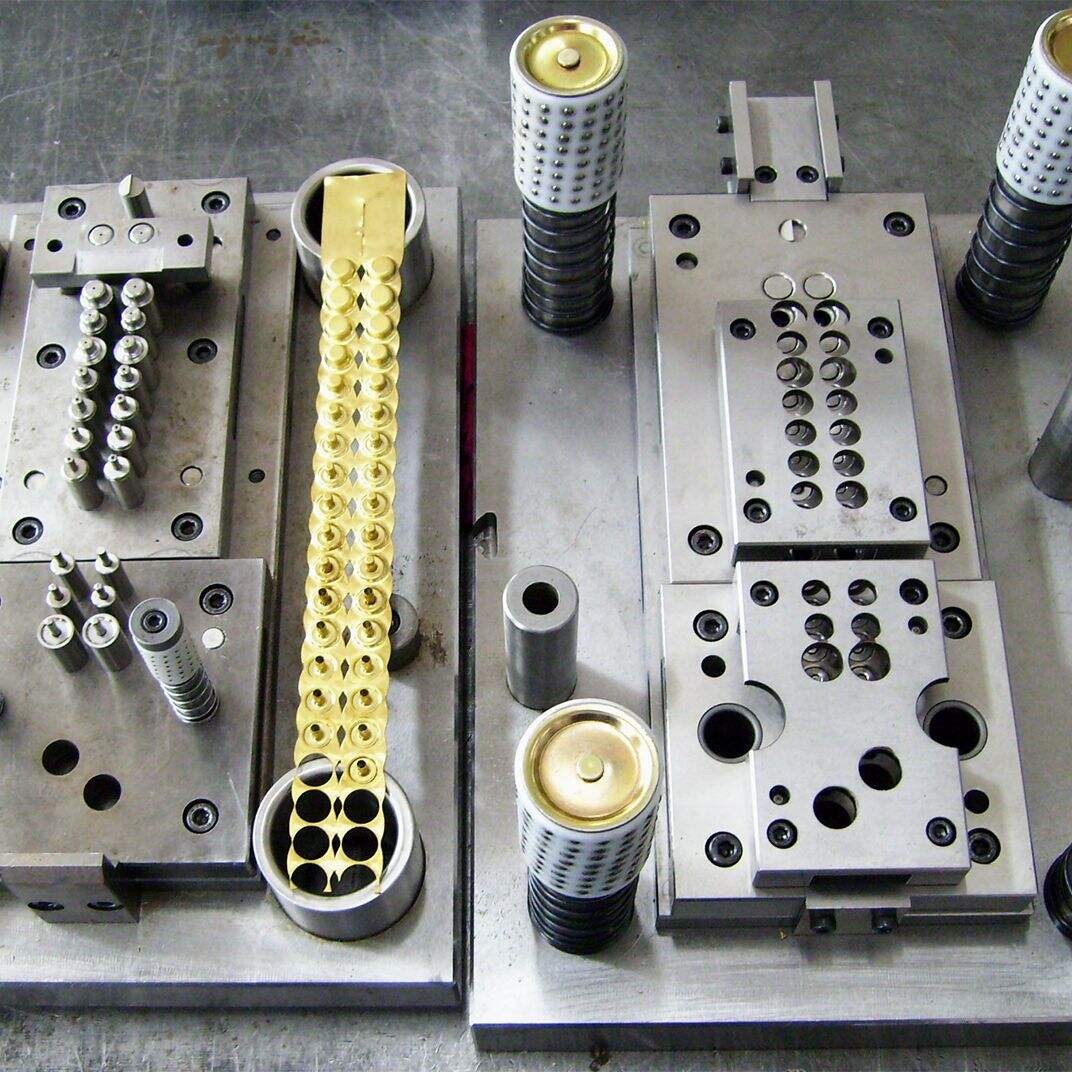

Sometimes factories will want to save time and costs while producing quality products. To meet this challenge, factories can adopt an automatic steel stamping dies that minimizes the number of workers required to unwind the steel coil. The Lihao steel uncoiler utilizes advanced automation technology, which makes it a great solution for factories that want to save time and money.

The Lihao steel uncoiling system has the ability to automatically recognize and uncoil steel coils with no manual input required. This avoid unwinding for need of worker, which reduce the labour in cost. This allows workers to attend to other crucial aspects of the production process. Not only does this automation help increase the capacity of the factory, but it also cuts down on turnaround times, thus increasing productivity.

Lihao steel uncoiling system built-in advanced sensors measures how tightly and fast the steel is unwound. This enables the system to control the speed and tension on unwinding so that there will be no harm to the material when it is being unwound. The machine provides high precision control that ensures steel do not lose quality in production, producing high-grade finishing products.

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our steel uncoiler offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.

Lihao Machine provides tailored solutions and comprehensive service meet up utilizing the varied needs of our customers. You can expect integrated services that include design, production and sales. Our R&committed D team give you with customized choices and technical discussions, ensuring that every option would be tailored with their certain needs.

we are focused on innovation and dependability, continuously updating our products and services. Our skilled Lihao team provides cutting-edge solutions helping to make us the most preferred option automation equipment found in stamping. We value customer and tend to be committed to providing top-quality equipment and exemplary solutions on a regular basis.