Potential hazard Industrial manufacturing processes from virtually all industries feature mechanical presses-or just plain presses, in their purest form. Going all the way back to 18th century factories, these machines provide the power and force needed to transform various materials into specified shapes and sizes. Lihao feeder for power press efficient, versatile and used traditionally in precision parts manufacturing industries like automotive, aerospace, machining of metal products, construction.

Mechanical presses, on the other hand fundamentally operate based on rotational energy into linear /straight line movement. The presses use a crankshaft that rotates to provide the force and pressure necessary for the operation at hand. Therefore, in rising and falling motion as the crankshaft turns into sliding mechanism with connecting rod then ram is set on action. The Lihao roll feeder machine final difference is that a mechanical press uses a flywheel to store energy and help in the process so as not harm its own operation. These are calculated based on the surface of the ram, and by what force we act upon (hydraulic or mechanical). In other words, the press is said to be more powerful when it has a larger ram size and requires of greater force

Gap Frame Press: One of the most common forms of mechanical press used in manufacturing, gap frame presses (also known as C type presses) offer unique versatility and ease-of-use/maintenance. This is in the list of many to use jScrollPane plugins

Straight Side Press: Made for high-volume production environments that require precision and repeatability, this type of mechanical press offers more rigidity than a gap-frame model can handle greater tonnage

Knuckle Joint Press: Used for high force and precision heavy-duty applications, Knuckle-joint mechanical presses are extensively used to form difficult materials like brass, copper and aluminium

H-Frame Presses - H-frame presses are optimal for heavy-duty tasks as they can process large sheets of metal and other materials, making them a perfect mechanical press. With robust structure and high strength, there are the best choice for metalworking and plastic molding

How Incremental Presses Work These specialized presses are used to form and bend metals using intricate shapes, suitable for a variety of applications where the finished product requires high precision with repeatable results without deformation.

Regular maintenance is an important factor to ensure the long-term precision and speed of mechanical presses. Regularly inspecting the various parts of the machine such as connecting rod, bearings and lubrication system is important to avoid downtime and retain optimal productivity. Following recommended service instructions from the manufacturer and responding quickly to mechanical problems are critical tips for keeping your press performing at its best. In addition, calibration on a regular basis is required to maintain the fine precision and accuracy of the press

Troubleshooting the press is essential to discover and correct problems if a machine breaks or malfunctions. Common problems for these engines are leaky hydraulics, worn components and jammed rams or crankshafts. If an entry in the troubleshooting is listed, it is recommended that safety hazard from internal damage to machine may occur and must be handled through trained personnel as described within

The Good and The Bad of Mechanical Presses

Between the hydraulic and pneumatic presses, mechanical press have several advantages. These are capable of providing more powerful and applying greater pressure as well as force for precision applications with power. In addition to this, a mechanical press will also produce accurate and consistent output - perfect for any job which requires precise positioning

However, mechanical presses have disadvantages as compared to hydraulic and pneumatic presses. They are more resistant to changing production requirements and consume much energy, making them not so environmentally friendly. On the down side however mechanical presses have fewer moving parts, and so are a little easier to maintain (there is less stuff that can go wrong).

Mechanical presses are here to stay and likely will dominate the manufacturing landscape as the industry moves closer toward automated solutions in this age of Industry 4.0 (and beyond). Because of this and their ability to deliver carefully-controlled force with reliable results, they are critical for many different applications. As mechanical presses continue to advance, they will likely benefit from technological advancements that turn them into more automated and intelligent systems having built-in sensors or even control systems. The Lihao coil handling equipment additional automation allows the presses to constantly adjust running parameters based on production needs and maximize their speeds

To sum up, a central piece of equipment in the industry is mechanical presses which offers force as well as precision for broad use purposes. Mechanical presses are expected to become increasingly sophisticated and intelligent, with the need for more advanced capability and productivity in manufacturing as automation takes over world Industry 4.0 transforms supply chains.

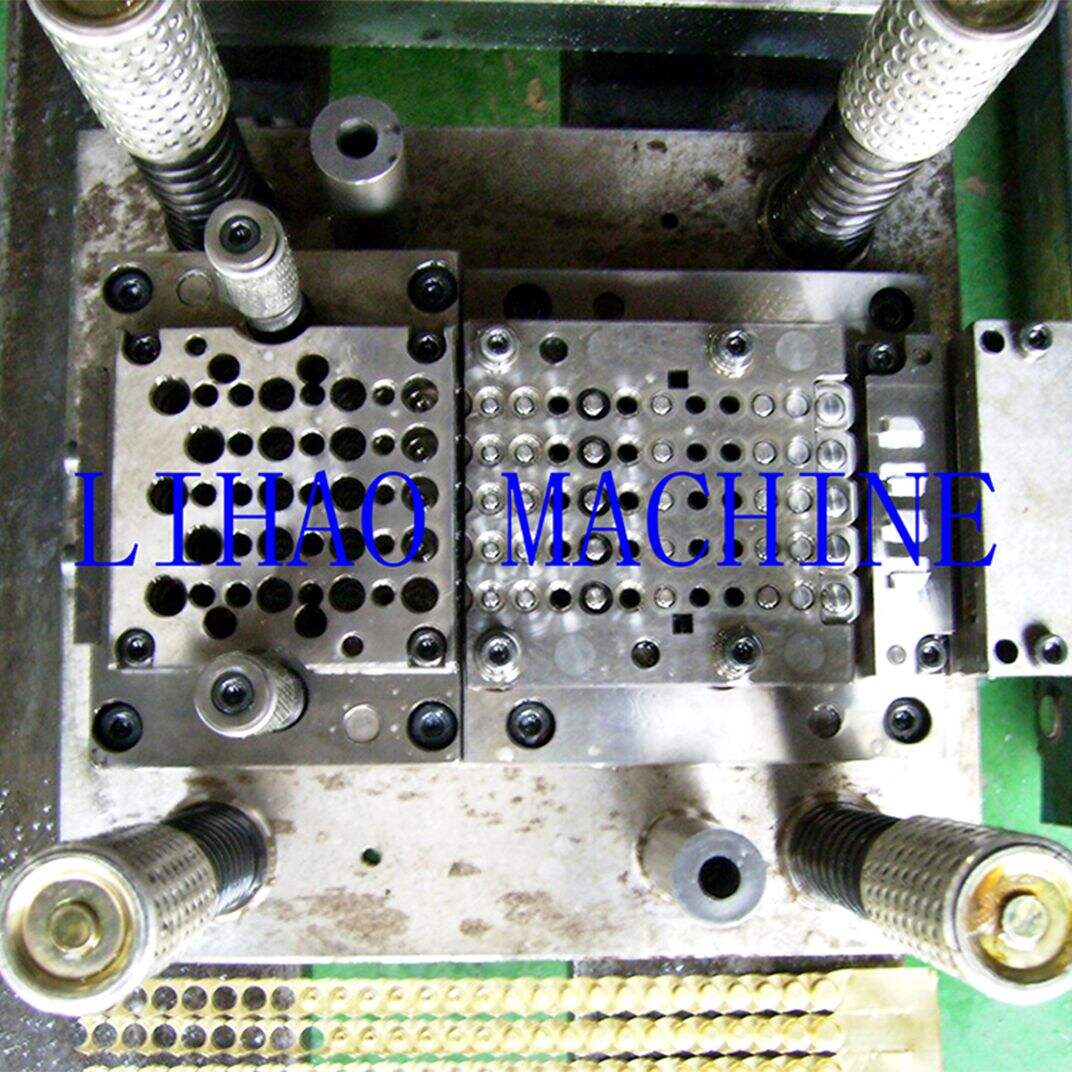

We have been specialists in the design and engineering of durable tooling that minimizes setup adjustments and production that is scrap is reduces. Our Mechanical press are able to deliver training that is global commissioning that ensures seamless integration and optimized performance globally. With in-house manufacturing plus quality parts that are spare we guarantee minimal interruptions plus the productivity this is certainly highest. As a ISO9001:2000 that is certified plus EU CE we abide by the high quality standards being highest.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.

Lihao Machine offers tailored solutions and complete services to fulfill different customer. We offering integrated services that encompass design, manufacturing and sales. Our committed R&D team will provide your with personalized alternatives and technical discussion guaranteeing each solution is perfectly customized to satisfy your own needs.