Mechanical press machine one of the unique tool utilize in factories to shape or cut various types of material. This plant is critical for the production of various every day purpose products. The basic principle is using electricity to spin a component —i.e., a flywheel. This flywheel generates energy to push down a ram onto a mold. It processes materials including metals/ plastics etc. and use high power production of machine ( force) to prepare a solid / durable product.

Amidst the fast-growing world, speed and quality are critical for businesses to build their products. The mechanical press machine is supporting a lot of factories to properly do this job. With such high force this machine has, materials can be very precisely and accurately shaped. This helps to ensure that the final products are of a high standard and comply with the relevant industry regulations. From larger business entities to smaller ones, mechanical press machines are an asset for any venture that aspires to produce great products in a limited time.

They are mechanical press machines to perform high precision and consistent work. They can utilize the energy from the flywheel to effectively aid end-users in controlling the press. Such tight control leads to consistent, trustworthy results. Mechanical press machines can perform the work with precision, which is why they are ideal for producing a large number of different products. Those items include bicycles, cars, airplanes and other big machines. These machines are one of the most important tools in various forms of manufacturing due to their speed, high accuracy and ability to work continuously.

As for factories, mechanical press machines have an important task. Their role is to provide the power needed to effectively shape and cut various materials. These machines are used in factories to bend sheets of metal into shapes such as cups, tubes, and plates. Various mechanical press available in different size for need of industries. The larger factories do not have a choice other than using bigger machines so that the machine can at least produce a good number of products. On the other hand smaller factories may prefer to use smaller machines according to their production capacity. Mechanical press machines break the raw material into useful finished products that humans need regardless of how big or small the machine is.

Mechanical press machines offer one of the most significant advantages to business owners by enabling items to be made faster while maintaining high quality. These machines have the ability to create multiple parts in a matter of time, so businesses can fulfil their customers orders on time. Lastly, using mechanical press machines guarantees that the material will have the same shape every time which minimizes errors. It is good for businesses because fewer mistakes mean reduced production costs. Businesses will be able to streamline their processes, create much faster and stronger production with all of the most couldnomenical benefits that accompanies it — they can work more effeciently, allowing them to having higher profits margins.

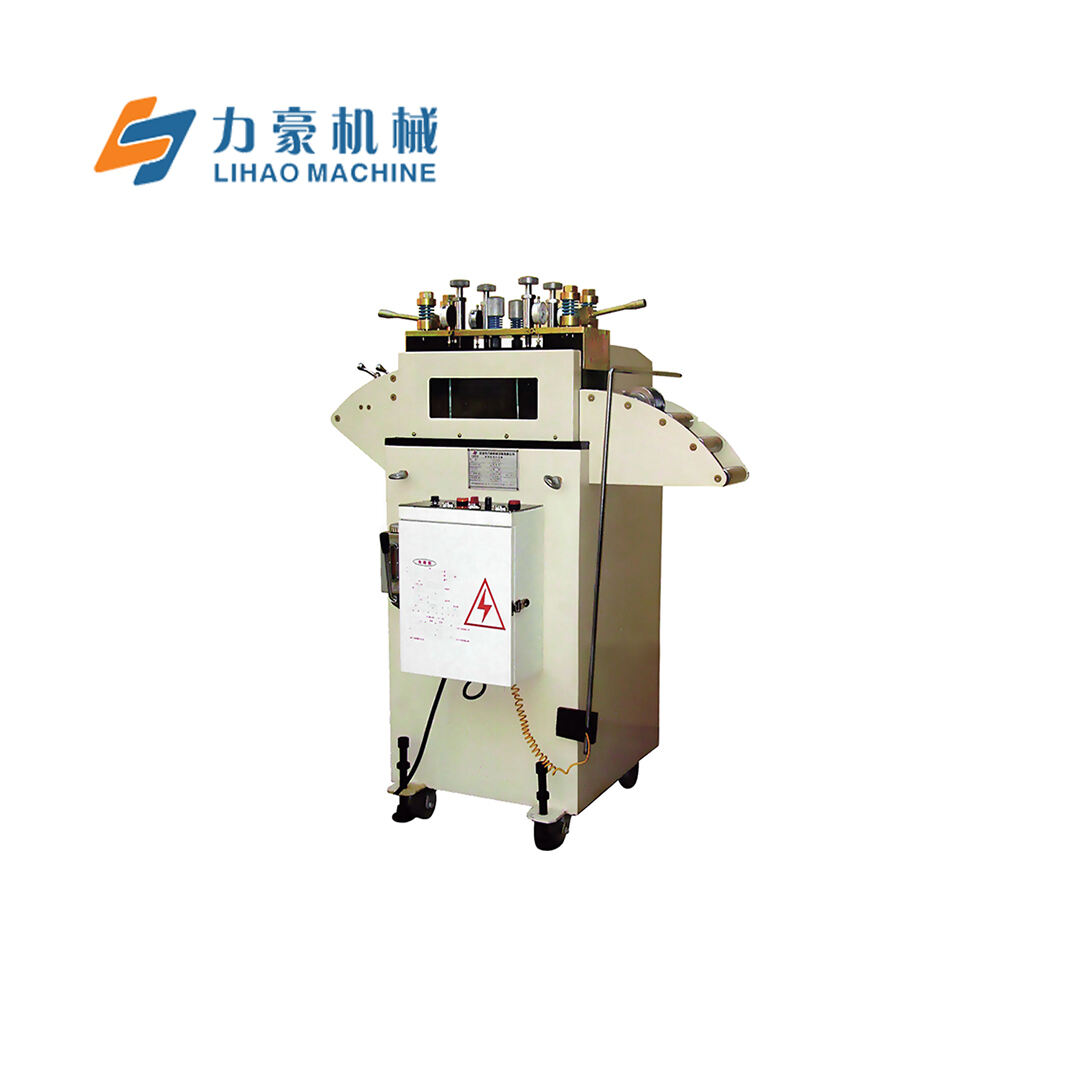

Lihao Machine has been a company that has been leading the field going back 26 years. It is an established supplier the domestic and international markets. Our items are used in various industries worldwide. And over twenty offices in China and an India branch overseas serve customers globally. Our advanced technology capabilities let us offering tailored solutions diverse industries.

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our mechanical power press machine offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.

Our dedication to innovation, improvement and continuous reliability of merchandise and services is a constant. Our Lihao group is very skilled while offering cutting-edge solutions. We have been the real no. 1 selection for stamping automation. We place the higher value client satisfaction, providing top-quality equipment and exemplary services everytime.

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.