Lihao specializes in the manufacture of custom metal stamping diess for a wide variety of applications in different industries. Our expert tradespersons, who are highly experienced in their trade, utilize unique tools and techniques to develop the mold which can automatically produce good quality metal products rapidly and economically. We start with designing a mould based on what our clients need and the specific requirements they provide. That's why the design is crucial so that one does not get what was not designed.

The design of the stamping dies required for metal stamping can be divided into different types. At Lihao, raw materials (including aluminum, brass, and steel) are transformed into finished products with various kinds of metal stamping molds. These can vary from basic components (e.g., brackets) to complex parts needed for use in various industries including automotive, aerospace, electronics, and healthcare. Our molds make those specific industry needs are way easier to meet.

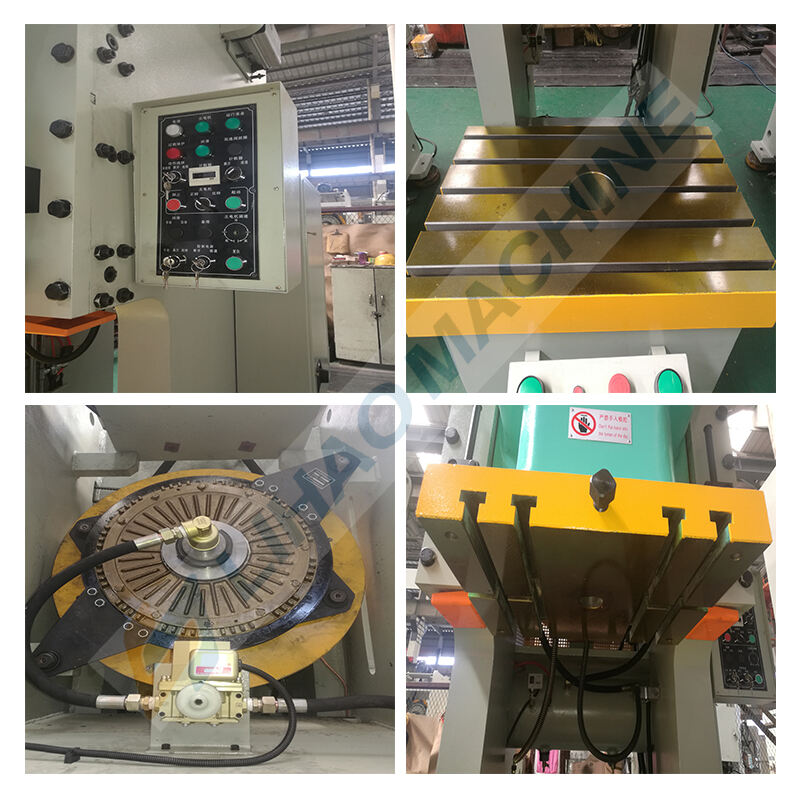

This forces us to adopt some hi-tech methods and use sophisticated machines for making metal stamping presss. Lihao focuses on producing high-quality products that meet the highest industry standards, making it strictly guided by the use of finest technology available. We craft custom metal stamping molds that can go a long way with very minimal downtime before they break apart to accomplish this level of quality.

The molds that these skilled workers make are very good, and there are different techniques used for the same. Let's take a look at the processes like electrical discharge machining, laser cutting and few others methods. These methods all serve to verify that our molds are manufactured with the utmost quality. We also use materials like steel, aluminum, and brass to make sure that the mold is durable and will last a long time while making great products. Our clients depend on consistent quality for their production, and the durability of this line is a big part of that.

Metal stamping molds increase the efficiency of manufacturing processes for us at Lihao as applicable in multiple sectors such as; automotive, aerospace, electronics and medical equipment. With metal stamping molds, our customers are responsible for producing units; we help them produce more smoothly. This also helps to cut expenses and make time-efficient production of quality products.

There are many different industrial applications for metal stamping molds. This is essential in industries such as automotive, aerospace, medical devices and electronics. We are Lihao, we design and manufacture metal stamping molds according to the various needs of clients from different industries. Every industry has its own requirement, and we design our molds accordingly.

Types of Parts We manufacture molds for various metal stamped products like brackets, heat sink, connectors, clips etc. Our team has a good command over technology and adaptable techniques to fabricate metal forming molds in compliance with the top-notch industry standards without compromising on quality parameters. This focus on quality is what removes all doubts from our clients mind, that they will get good products every single time.

And over 26 years experience in industry leadership, Lihao Machine is a supplier which was top the domestic and international markets. Our products is widely found in a wide range of. All over the world with nearly 20 offices across China because well as an overseas subsidiary India we provide our clients. We provide customized solutions in several industries, with your robust technological abilities.

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.

Our dedication to quality, improvement and continuous reliability of products and service is a constant. Our Lihao team is extremely skilled and offers cutting-edge systems. Our company is the stamping possibility first automation. We have been focused on client satisfaction, providing top-quality products outstanding service.

We are specialists in engineering and robust design of tools, which helps in reducing set-up adjustments and scrap production that is reducing. Our metal stamping mold offer worldwide training and commissioning to make sure performance this is certainly optimal seamless integration across the planet. We guarantee maximum efficiency plus minimized downtime by providing in-house production, high-quality spare parts, and support which is ongoing. As a ISO9001:2000 that is certified and EU CE We uphold the best standards of quality.