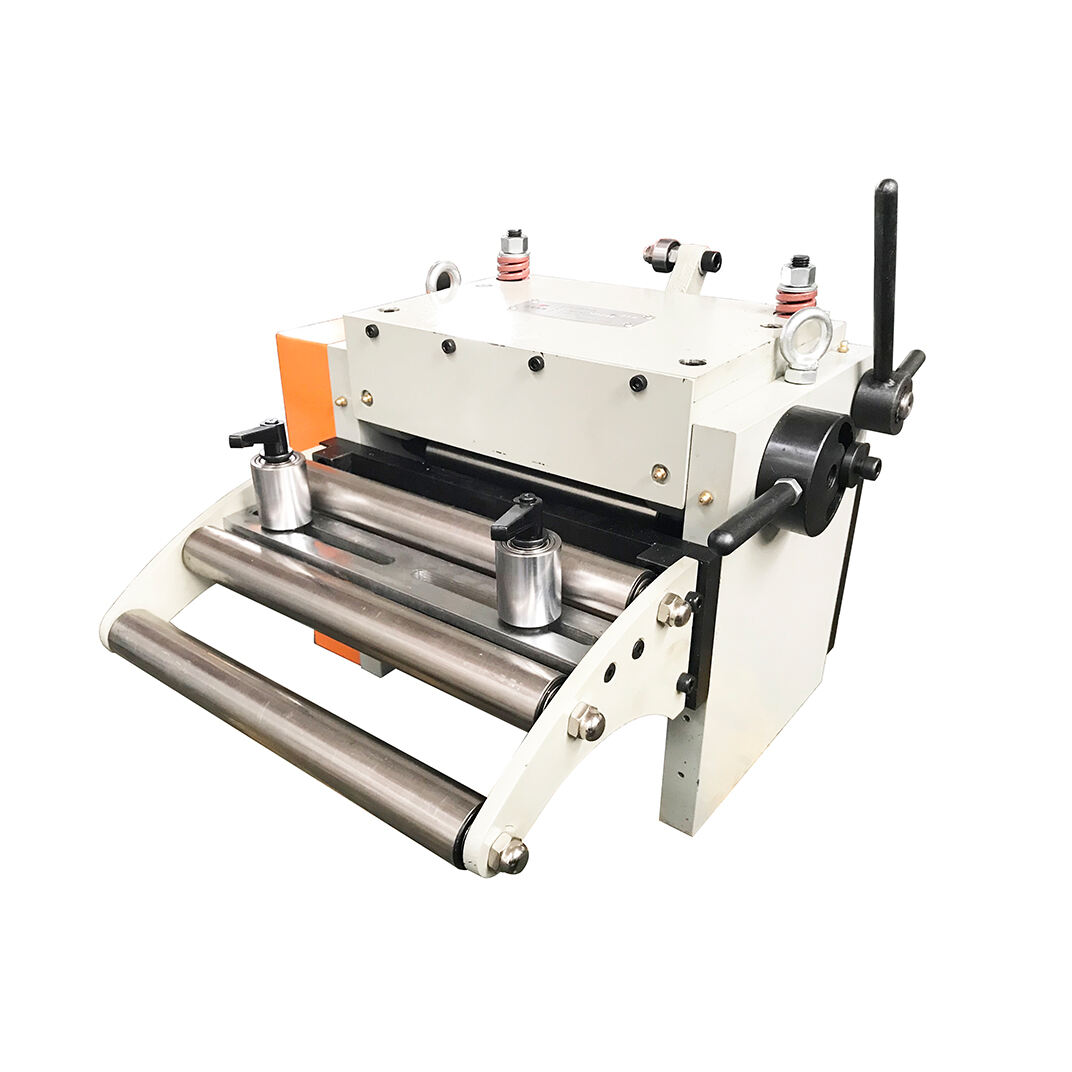

Have you heard of progressive stamping dies? There are some specialized tools used for eliminating and moulding a variety of metals into various components, parts or products. They more like step or stage machines. While each stage produces more components on the sheet exiting the die until you end up with a finished bushing that ready for installation. As a result, creating layouts and shapes becomes easier.

This is only achievable due to the unprecedented production speeds with progressive stamping from Lihao. They save transporting a metal sheet manually from one stage to another, and are done automatically. So workers aren't wasting their time carrying the metal and are doing something more important for finesse. As no human is involved in this, so a huge time and energy has been saved. In return, this allows for the creation of thousands or more parts to be produced quickly and cost-efficiently.

One major benefit of progressive stamping dies is that they help organizations in managing the costs. However, in automated process next to no work is required before people start working eliminating a majority of manual work which reduces production costs by many folds. Additionally, because these Lihao dies are intended to generate precision parts, there is less scrap during the stamping process. This is even cost-effective since equates to the purchase of a fewer raw material can help in saving much time and money by not converting an excess amount of unnecessary raw materials into finally the end product.

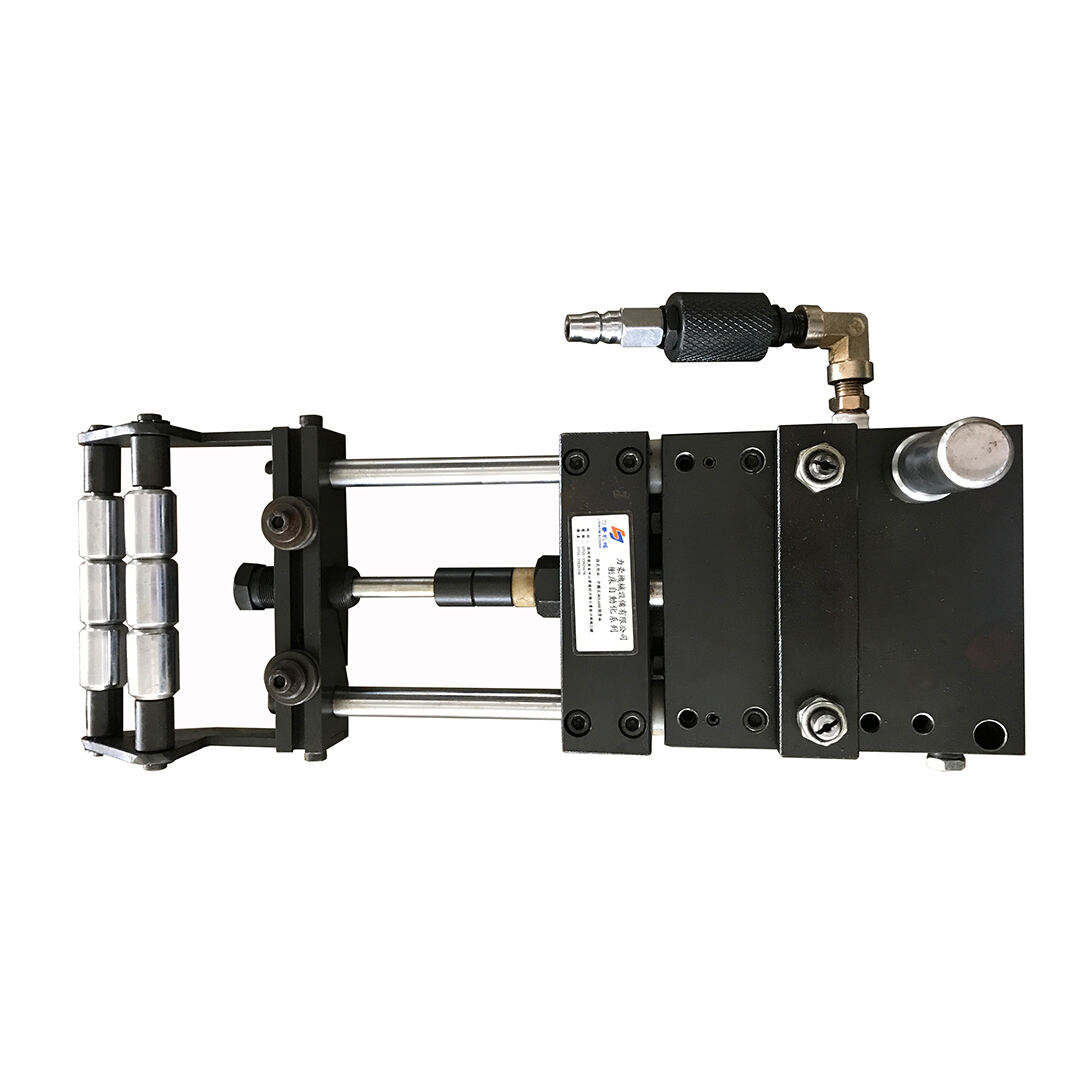

Result-oriented (so they can actually create products) Precision progressive dies are made using some very accurate measuring tools. These are the tools you will need to ensure that all cuts and bends are perfect. The Lihao stamping die really are meant to match — interpreting no pressure later on. Cylindrical grinding creates a higher level of accuracy which will translate into superior parts and lowers production times.

One of the greatest benefits to progressive stamping is that it allows companies to produce more volume in less time. In the past, semi towers were not really easy to stamping at high yield and high volume loads speed that is needed but also a strong machine production worked towards as well. In progressive stamping, you can set up the dies so that they do their work as quickly and efficiently as possible. This allows companies to produce error-free parts at a higher volume, without sacrificing quality.

The last, and not the least, Progressive die ensures you will have consistency in production — each of your unique parts are created identically to one another when using progressive stamping dies. This ability is essential in sectors like automotive or electronics, where identical parts need to look identical. When customers are delivered the same parts time after time it allows them to have faith in a company's product, as they should now know what to expect from that progressive die stamping manufacturer.

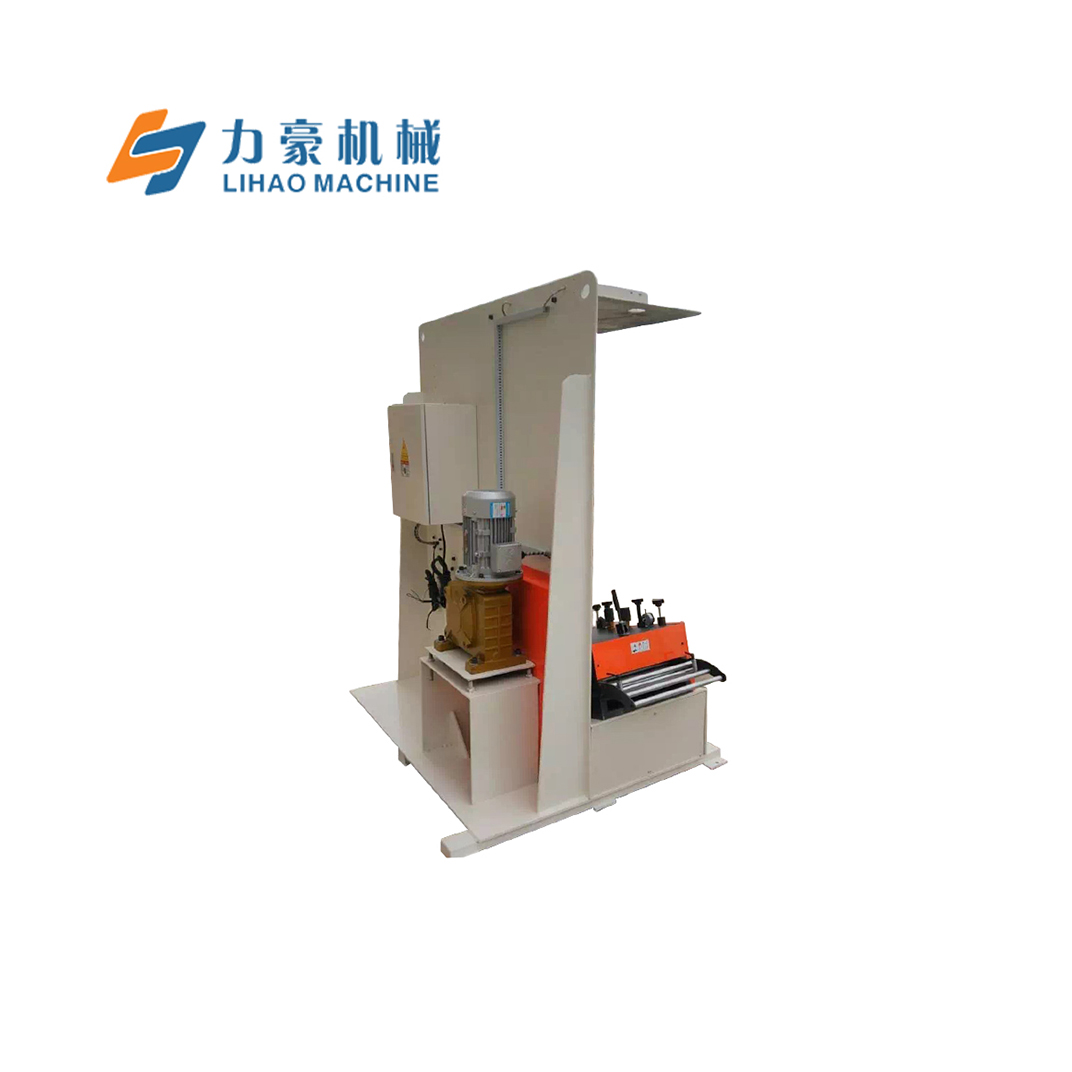

Lihao Machine provides tailored solutions and comprehensive service meet up utilizing the varied needs of our customers. You can expect integrated services that include design, production and sales. Our R&committed D team give you with customized choices and technical discussions, ensuring that every option would be tailored with their certain needs.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our Progressive stamping dies offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.

Lihao machine has been a frontrunner in the marketplace for more than 26 years. It is a reliable supplier on the domestic plus international markets. Our products are widely found in various industries worldwide. We provide our customers worldwide through additional than 20 offices around Asia and an indian subsidiary. We offer tailored solutions across various industries many thanks your extensive technology capabilities.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.