Lihao is a unique company for stamping mold. These molds are crucial since they are used in factories to imprint designs to a wide variety of products. Examples of these products are car parts made of metal, as well as fun toys made of plastic for children. The molds must also be very precise so that the stamping is correct and looks good, so they must fit perfectly.

Lihao does this with high-tech machines to produce very precise molds. They computer-design the molds in detail. Then, once the design is ready, the machines cut them out of metal. This process is very exact so that every stamp will look the same, and the product is perfect every single time.

In fact some of the best things about stamping mould, is that you can make your own design. What this means is that you can really spread those creative wings and create some stunningly beautiful products! You could come up with fun shapes, letters, and symbols that you would like to have printed on your product.

Lihao has a great team of designers that can work with you for a mold specializing just for you You could make a mold that says your name on it in a special way. Or else you could create a mold that creates a distinctive shape, such as a star or a heart. There are endless possibilities for creativity, and you can think of so much!

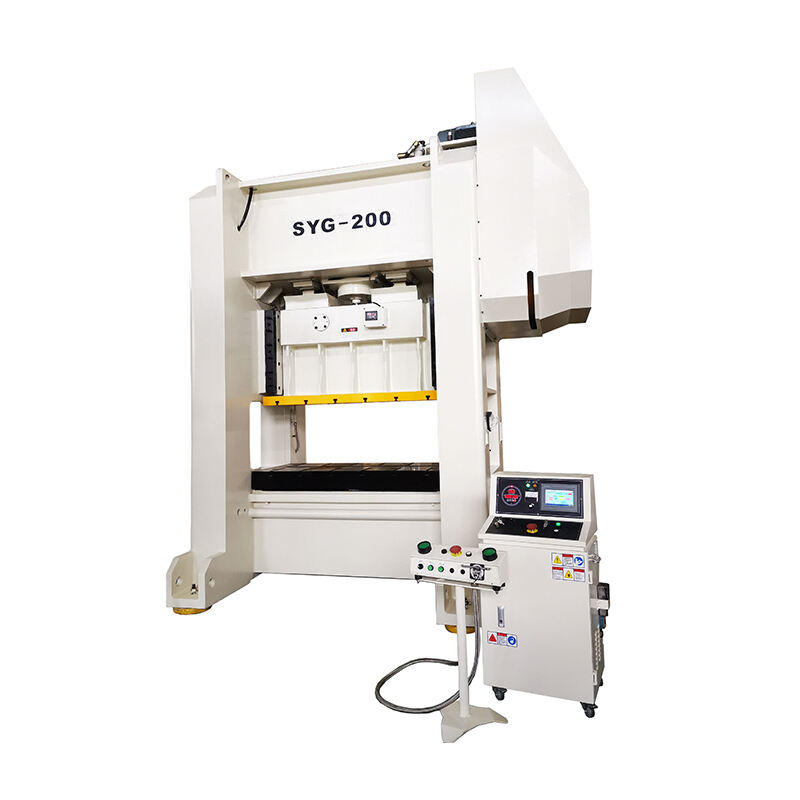

Lihao's stamping molds are highly intelligent and designed for high automation. The products are manufactured effectively and rapidly, and as a consequence, factories are in a position to create colossal quantities of products in a little period. This saves money as well as expedites getting products into the customers’ hands so they can start enjoying them immediately.

Stamping molds at Lihao can use various materials dose any factory needs it for its products. It can use heavy materials like steel, lightweight material like aluminum or even plastic. Every material has its advantages, and Lihao can assist you in selecting the ideal material for the specific task you have planned.

Thus, the molds can be created using other methods or techniques. For example, some molds (known as injections) are done by injecting hot plastic into the cavity for creating the mold. Other molds are created using CNC machining, which is a computer-controlled process that cuts the mold out with extreme precision.

we are focused on innovation and dependability, continuously updating our products and services. Our skilled Lihao team provides cutting-edge solutions helping to make us the most preferred option automation equipment found in stamping. We value customer and tend to be committed to providing top-quality equipment and exemplary solutions on a regular basis.

Lihao machine has been a leader on the market since 1996. It had been a reliable supplier regarding the national and international markets. Our items are used throughout the selection of industries around the world. We offer our clients worldwide with more than 20 offices in China additionally the branch in India. Our robust technological capabilities enable customized solutions for a variety of industries.

Lihao Machine provides tailored solutions also a complete site meet various needs of clients. With a wide assortment of, including three-in feeders-one Cum Straightener machines, NC servo feeders, plus punch machines, we offer comprehensive service for manufacturing, design and sales, also service plus trading. Our R&committed D team personalized options and technical discussions, guaranteeing each solution is completely designed to fulfill your preferences.

Our company is experts in the development and design of durable tooling that can help to attenuate setup adjustments too as reduces scrap production. Our stamping molds offering training that is worldwide commissioning, which ensures the performance which is highest and seamless integration around the world. With your very manufacturing that is own and high-quality spare parts service we guarantee minimal interruptions in addition to productivity that is highest. We are ISO9001:2000 accredited and EU CE certified.