Mašina za špicanje je ekstremno težaka i moćna mašina koja se koristi za sijanje trake velikog spiralenog oceola na željene veličine. To je ključno, jer se svi ti manji dijelovi koriste u svemu od automobila do zgrada i kućanskih uređaja. Upravo izvršeno sijanje oceola omogućava lakše korištenje i omogućuje bolje proizvode.

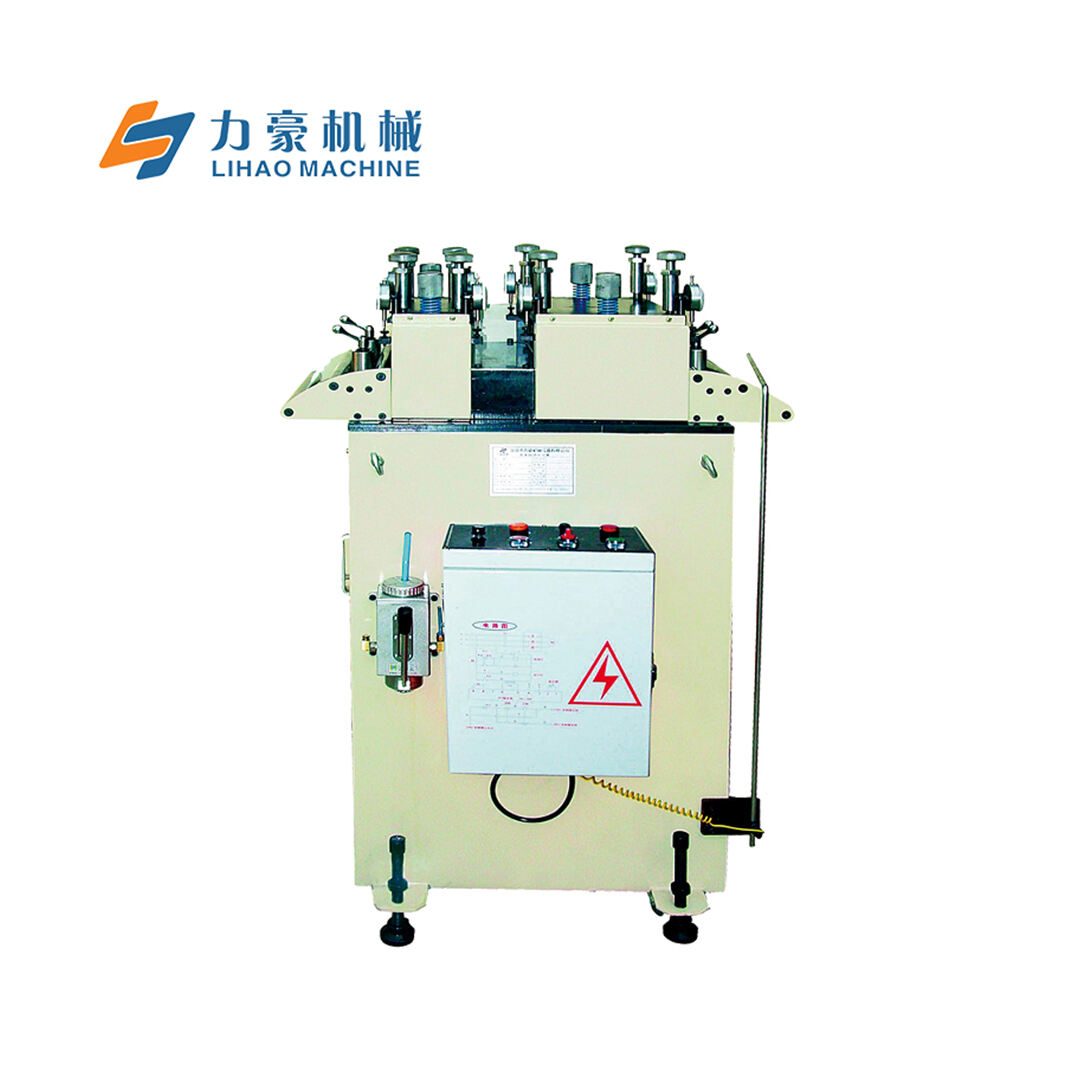

A Lihao čeljustno štapna mašina pruža neke odlične prednosti koje pomažu poslovima da djeluju učinkovitije. Dakle, ova mašina precizno šjeće, ali prije nego što može šjeci, implikacija je da se čelik može upotrijebiti mnogo učinkovitije, time smanjujući otpad. Stoga, smanjenje otpada čelika nije samo lako za vašu žep, već i za Majku prirodu.

Drugo, ova mašina štedi puno vremena jer automatski šije čelik. Umjesto da biste plaćali desetke radnika da obavljaju šijecu ručno, mašina šije mnogo brže. To u suštini znači da poslovi mogu proizvesti mnogo više čelikastih roba u kraćim vremenskim razmacima. Omogućuje im da zadovolje potrepštine svojih kupaca učinkovito.

Ako posedujete Lihao čeljuste koil šit , evo nekoliko osnovnih stvari koje bi trebale učiniti kako biste se uvjerili da radi najbolje moguće. Prvo, osigurajte se da je mašina uvijek u dobrom stanju i redovito ju provjeravajte. To znači provjeriti da li sve funkcioniše ispravno i riješiti manje probleme prije nego što postanu značajniji. Ako se brinete o mašini, ona će savršeno raditi i nikada neće neočekivano poštedjeti.

Na kraju, treba napomenuti da bez dobrih operatera nećete iskoristiti stroj u potpunosti. S pravom obukom i podrškom zaposlenih, oni će biti svjesni kako ispravno koristiti stroj. Operateri s znanjem i iskustvom, koji su sigurni u rad s strojem, mogu ga dovesti do maksimalnog potencijala, što vodi do efikasne proizvodnje.

Sljedeći je deo razvitka, koji je dio stroja koji rasvlači ocel iz mašine. Ovo je važan korak pri spremanju oceola za sjecanje. Nakon što se ocel raspakuje, ravnala čini širinu ocela ravnom i ravnom upravo prije nego što se sječe. Ovaj korak je ključan jer mora biti ravan; ako nije, može izazvati probleme tijekom sjecanja.

Postoje nekoliko ključnih razmatranja prilikom izbora linije za špicanje ocele Lihao. Vrsta i veličina oceola koju namjeravate koristiti treba biti vaša prioritetna razmjerna točka. Različiti poslovi zahtijevaju različite mašine. Ako se posebno bavite debljim ocelom, onda ćete trebati jačinu da presijete napetost debljeg materijala, što nije slučaj kod tankog oceola. Trebate odabrati mašinu koja će ispunjavati vaše potrebe.

Lihao Machine pruža prilagođena rješenja te i potpuni servis koji zadovoljava različite potrebe stranaka. Možete očekivati integrirana rješenja koja obuhvataju dizajn, proizvodnju i prodaju. Naš tim za istraživanje i razvoj (R&D) vam pruža prilagođene izbore i tehničke rasprave, osiguravajući da će svaka opcija biti prilagođena vašim jedinstvenim kriterijima.

Odlično radimo na području inženjerstva i dizajniranja izdržljivih alata, što smanjuje prilagodbe na vašem uređaju i smanjuje proizvodnju koja je otpad. Naša mašina za rezanje čelika nudi svetsku puštanje u rad i obuku koja osigurava integriranje bez problema i maksimalne performanse širom svijeta. Sa vlastitom proizvodnjom i kvalitetnim rezervnim dijelovima osiguravamo minimalne prekide, dok je produktivnost najveća. Imamo ISO9001 certifikat i CE certifikat koji je EU certifikat.

Naša posvećenost kvalitetu, unapređenju i neprestanoj pouzdanosti proizvoda i usluga je stalna. Naš tim Lihao je izuzetno vještinovit i nudi najnovije sisteme. Naše tvrtke je mogućnost talijanja prva automacija. Fokusirali smo se na zadovoljstvo klijenata, pružajući vrhunske proizvode i odličnu uslugu.

Lihao stroj je već preko 26 godina bio vodeći na tržištu. Bio je pouzdan izvornik na domaćem i međunarodnom tržištu. Naše proizvode možete pronaći u raznim industrijskim granama širom svijeta. Pružamo naše klijente širom svijeta preko više od 20 ureda u Aziji i jedne podružnice u Indiji. Ponuditi prilagođena rješenja u različitim industrijskim granama zahvaljujući svojim obsežnim tehnološkim mogućnostima.