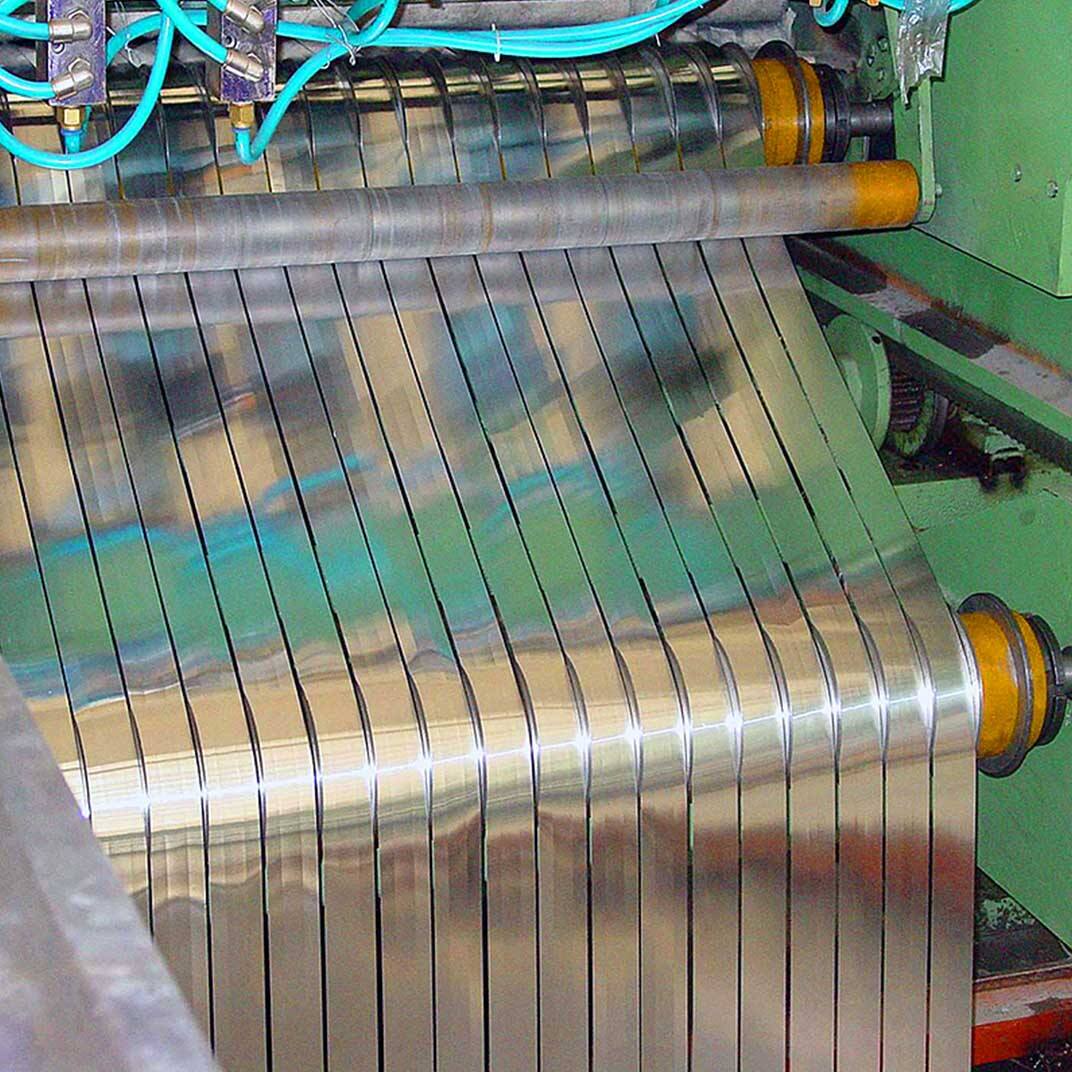

Automated Slitting Machina, praecisis Coils Using Slitting Blades

- 1. Linea nostra declivia efficaciter tractat gyros variarum specificationum, inconsutilem transitum a defluxu ad declivem ac repulsum, gyros cuiusvis latitudinis requisitae producens.

- 2. Est versatile in amplis globis metallicis, incluso ferro frigido involuto, calido ferro involuto, chalybe immaculato, chalybe galvanizato, alumine, chalybe Pii, ferro colorato, vel picto ferro.

- 3. Late adoptavit trans laminam metallicam processus industriam, nostra linea declivis applicationes in fabricando automotiva, continente productione, supellectili fabricando, sarcinas, materias fabricando, et plura invenit.

Productum Descriptio

Descriptio Instrumentorum

(Parametri Rotoris Possunt Essentialem Modum Secundum Requisitiones Clientium)

Machina scindendi

1. Structura Corporis: Tota Conflatim Sutura et Stress Relieved. Tria Tabulae Fundamentales Crassae 30mm pro Maiori Stabilitate.

2. Designatio Absorptionis Impetus: Corpus Machinae Dispositum cum Portis Apertis ad Addendum Materiales Absorptivas; Motor et Rotor Incisivus Separati, Conecti per Articulationes Universales.

3. Designus Fusi: Fusus inferior fixus; mecanismus levationis manualis movet fusum superiorem. Arches mobilis est in linearibus glissieribus pro remotione manu, facilitando commutationem instrumentorum.

4. Materialis et Tractamentum Fusi: Fusi inferior et superior ex forgings 42CrMn, subiecti tractamento quenching, cum duretate superficiei HRC52-57. Diametrus fusi est Φ120mm (+0 vel -0.03mm), cum longitudine effectiva 1300mm.

5. Systema Propulsionis: Motor AC 7.5Kw variabilis frequentia controlatus propellit fusum inferiorem, cum intervallo velocitatis adjustabili 0-120 rpm. Fusus superior propulsatur per transmissionem dentatam.

6. Altitudinis Fusi Inferioris: 800mm.

7. Praecisio Fusi:

- Concentricitas Fusi: Mensurata cum tribus indicatoribus (laevus, medium, dexter), cum tolerantia ±0.01mm (fusus inferior primarius, fusus superior secundarius).

- Parallelismus Fusi: Latus laevum et dextrum installatum cum lamminis superioribus et inferioribus symmetricalibus, correctum usque ad lamellas tactus. Focussus principalis correctionis in fusum superiorem, cum tolerantia ±0.01mm.

- Parallelism of Shaft Side: Measured with indicators to ensure correct shaft starting position, with tolerance of ±0.005mm.

8. Blades: Recommend the use of hard alloy material with hardness reaching HRA90-95. Optimized combination of blades and spacers to meet slitting specifications. (Blades and spacers not included in the equipment; subject to separate negotiation based on customer requirements.)

Edge Recoiler

1. Drive System: Recoiler driven by a Torque motor from the Shunda brand (tension motor) to ensure stable coiling process.

2. Discharging Device: Discharging device controlled by motor and frequency converter to ensure uniform distribution of coil material, ensuring effective recoiling of edge materials.

3. Cage Drum: Designed with a cage drum for convenient and rapid unloading process.

4. Entry and Exit Bridge: Motor-controlled entry and exit bridges.

5. Bridge Surface: Covered with 8mm thick plain stainless steel plates for increased wear resistance and ease of cleaning.

6. Designus Axonis Rotatorii: Utitur axonibus rotatoriis altae duritiae cum crassata electroplating ad augeandam resistenciam usus et vitam servicii.

I.Caracteres

1. Praebens dispositionem bene ordinatam, automationem completam, et efficaciam sine pari, productivitatem, praecisionem, et qualitatem, linea nostra scissoria operationem fluentem certatim cum performance constante et controllis amicabilibus utenti securat.

2. Utendo systemate controlis Mitsubishi PLC progressivo, linea nostra scissoria praecisionem globalem optime administrat pro performance optima.

3. Systemata optionalia CPC & EPC ad praestandum maiorem exactitudinem decoilandi et recoilandi disponuntur, flexibilitatem additam ad requisita specifica satisfacienda praebentes.

4. Munimentis hydraulico fide digno, structura robusta, et configurationibus rationabilibus locorum, linea nostra scissoria commoditatem et practicabilitatem offert, fiduciam et stabilitatem in operatione garantians.

ⅱ .Componentes Principales

1. Plaustrum circuli

2. Explicator circuli

3. Dispositum comprimentium, Rectificator et Machina sectilis

4. Circulator

5. Latus dirigens

6. Scindens machina

7. Reliquiae recolligator (utrumque latus)

8. Circulator

9. Separator et tensio apparatus

10. Recolligator

11. Descaricatorium pro recolligatore

12. Systema hydraulicum

13. Systema pneumaticum

14. Systema controlis electricum

ⅲ .Processus technicus

Vehiculum spire → expandere spira → comprimere, dirigere et secare caput spire → acumulator → dirigere → scindere → convolvulus lateralis → acumulator → praeparatio materialis, tensio → reconvolvulus → vehiculum deponendi

ⅴ.Parametrus

| Exemplum |

Latitudo (mm) |

Crassitudo (mm) |

Ponderatio Coil (tonellus) |

Fasciae scindentur |

Celeritas Secandi (m\/min) |

Area pavimentum (m) |

| LH-SL-1050 | 1000 | 0.2-3mm | 1-8 | 2-20 | 0-120 | 5×16 |

| LH-SL-1300 | 1250 | 0.2-3mm | 1-10 | 2-20 | 0-120 | 6×18 |

| LH-SL-1500 | 1450 | 0.2-3mm | 1-15 | 2-20 | 0-120 | 6×19 |

| LH-SL-1650 | 1600 | 0.2-3mm | 1-15 | 2-20 | 0-120 | 8×20 |

NOTA: Machina ad clientis particularem petitionem componi potest, praedicta particularia tantum ad consultationem.