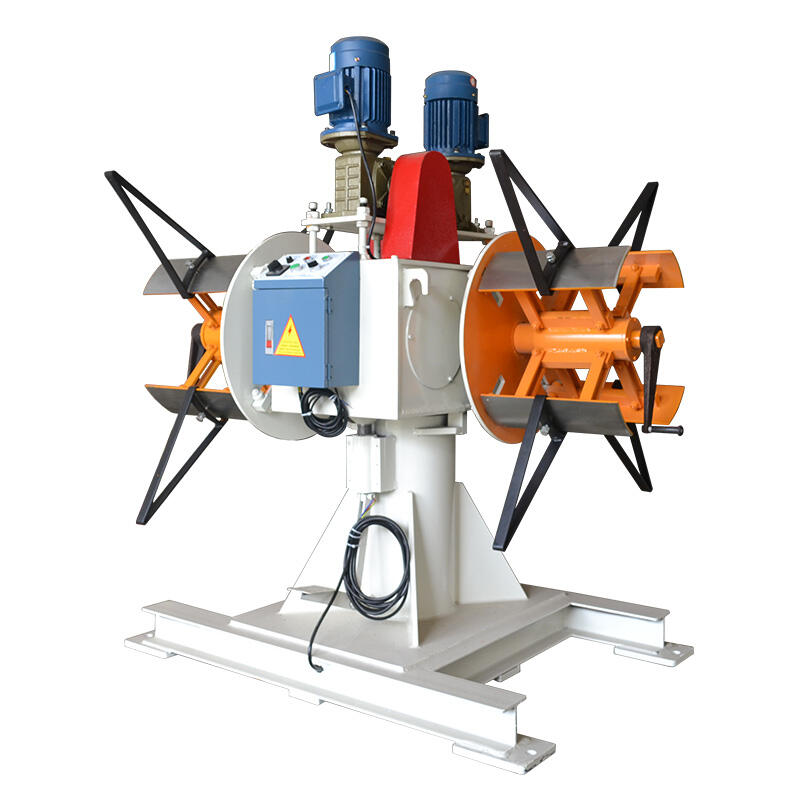

ເຄື່ອງ Press ກັບ Servo Feeders ໃນການຜະລິດ. ໃນສາຂາທີ່ການປະຕົກເມືອງເປັນຫນ້າສຳຄັນຂອງໂຄງການ, เຄື່ອງ press ກັບ servo feeders ໄດ້ເປັນເຄື່ອງຈັກທີ່ຕ້ອງການ. ມັນໄດ້ປ່ຽນແປງວິທີການເຮັດວຽກຂອງເหลັກຊຸດແລະເມື່ອງເພີ່ມອື່ນໆ. ທັງໝົດໄດ້ຖືກອອກແບບໃນການເພີ່ມອັດຕາການຜະລິດແລະເຮັດໃຫ້ສິນຄ້າມີຄຸນຄ່າທີ່ຍິ່ງຂຶ້ນ. เຄື່ອງ press ກັບ servo feeders ໄດ້ເສຍເວລານ້ອຍກວ່າເຄື່ອງຈັກທົ່ວໄປແລະຜະລິດສິນຄ້າທີ່ມີຄຸນຄ່າສູງກວ່າ. ແລະການໃຊ້ເຄື່ອງ press ກັບ servo feeders ຂອງ Lihao ໄດ້ມີຄວາມສຳເລັດໃນການເພີ່ມຄວາມเรົ່າແລະຄວາມສັບສົນ. ເຄື່ອງສະຫນິດ Feeder ຜະລິດສິນຄ້າທີ່ມີຄຸນຄ່າສູງ ເຊິ່ງຕ້ອງການເສຍເວລານ້ອຍກວ່າທີ່ຈະຕ້ອງການໃນກໍາເນີດທີ່ແມ່ນແຫຼ່ງ. ມັນສາມາດເຮັດໄດ້ເນື່ອງຈາກມັນໃຊ້ມอเตີ້ທີ່ພິเศษແລະເทັກນົ罗ີເຊື້ອຊົ່ງເປັນເປີດໃຫ້ມັນຍ້າຍໄປໃນທີ່ທີ່ມີຄວາມແນວແລະສະຫນາມ. ເນັ້ນ, ຜູ້ຜະລິດສາມາດຜະລິດອົງປະກອບໄດ້ເรົາແລະເສຍເວລານ້ອຍກວ່າກ່ອນ ເຊິ່ງບັນຫາເງິນທັງໝົດ.

ຄວາມໄວ - เຄື່ອງປະຕິບັດ Servo ທີ່ Lihao ກໍ່ແມ່ນຄວາມໄວຫຼາຍ. ຕົວເຄື່ອງສາມາດເຮັດວຽກໄດ້ຂະຫຍາຍແລະເสถິຍທີ່ສຸດ ທີ່ເປັນສິ່ງທີ່ຈຳເປັນສຳລັບຜູ້ທີ່ຕ້ອງການຜົນຕົວຫຼາຍ. ນີ້ແມ່ນເຫດຜົນທີ່ສູງສຸດທີ່ຫຼາຍໆໂຮງແຮມໃຊ້ເຄື່ອງປະຕິບັດ Servo. ອື່ນໆທີ່ເປັນຄວາມສຸດຂອງການໃຊ້ໂຣບອດແຄርເທຊຽນແມ່ນຊ່ວຍໃຫ້ຜູ້ຜະລິດສຳເລັດປາຍທາງການຜົນຕົວແລະຜົນຕົ້ນທີ່ມີຄຸณພາບດີທີ່ສຸດ. ຄວາມສຸດຂອງເຄື່ອງປະຕິບັດ Servo ເປັນວ່າທ່ານສາມາດຄົ້ນຄວາມໄວຂອງມັນໄດ້. ດັ່ງນັ້ນ ພະນັກງານສາມາດໃຫ້ເຄື່ອງຈັກເຮັດວຽກໄດ້ທີ່ຄວາມໄວຕ່າງກັນ - ລົງຄະແນນກັບຄວາມຕ້ອງການຂອງເສັ້ນຜົນຕົວຂອງພວກເຂົາ. ຜູ້ຜະລິດສາມາດຕັ້ງຄວາມໄວເພື່ອສາມາດຮັບກັບວິທີ້ຜົນຕົວຂອງພວກເຂົາສຳລັບຄວາມສຸດຂອງຄວາມມີຄວາມສຸດ. ເຄື່ອງຕັດຄອຍ ສະຫນັບສະຫນູນທີ່ບໍ່ສາມາດເປັນເປັນເງິນທີ່ບໍ່ສາມາດເປັນເປັນເງິນ.

ເຄື່ອງປະຕິບັດ Servo feeder ຂອງ Lihao ເຍິງແມ່ນຊ່ວຍໃຫ້ຜູ້ผลິດລົດສາມາດຈຳນວນການພິມທີ່ບໍ່ສຳເລັດແລະການຢຸດເວລາ. ເຄື່ອງເຂົ້າເຫຼົ່ານີ້ຖືກຕິດຕາມ (ໂດຍອອນໄລນ์) ເພື່ອໃຫ້ສາມາດລາຍງານບັນຫາທີ່ເກີດຂຶ້ນ. ຖ້າມີບັນຫາ, ມັນຈະໄດ້ຮັບການແກ້ໄຂທີ່ເรົາວ່າງເພື່ອບໍ່ໃຫ້ປ່ຽນການຜະລິດ. ນີ້ຊ່ວຍໃຫ້ການເຮັດວຽກເປັນໄປ້ອນແລະປ້ອງກັນບັນຫາທີ່ສາມາດເกີດຂຶ້ນທີ່ສາມາດເຮັດໃຫ້ເວລາ, ອົງການແລະເງິນເສຍໄປ. ເຄື່ອງປະຕິບັດ Servo feeder ເປັນທີ່ນິຍົມໃຊ້ຫຼາຍທີ່ສຸດໂດຍຜູ້ຜະລິດລົດ. servo feeding line ເຄື່ອງເຂົ້າເຫຼົ່ານີ້ມີຄວາມຮູ້ທີ່ຈະຜະລິດອົງປະກອບທີ່ຕ້ອງການທັງຄົນລົງແລະສາມາດປະສານກັນໄດ້. เຄື່ອງປະຕິບັດ Servo feeder ກຳລັງໃຊ້ເทັກນົ罗ທີ່ສັງຄານກວ່າທີ່ຈະສາມາດຜະລິດຮູບແບບທີ່ສາມາດປັບປຸງໃນອຸດົມສາຫະພັນທີ່เขັມແຂງ. ຕົວເລືອກທີ່ສຳຄັນໃນໂລກຂອງລົດທີ່ສັງຄານກວ່າເປັນເລື່ອງທີ່ສຳພັນຕໍ່ຊີວິດແລະເສຍຊີວິດ!

Нако ບໍ່ແມ່ນພຽງແຕ່ວ່າ ເຄື່ອງປະຕິບັດສະເລ່ຍທີ່ຖືກໃຊ້ໂດຍເຄື່ອງຂົນຫນ້າເຫຼົ່ານີ້. ການໄດ້ຮັບຜົນປະໂຫຍດທີ່ຖືກຈັດສົ່ງຍັງເປັນເຫດຜົນທີ່ເຮັດໃຫ້ຄວາມນິຍົມຂອງມັນເພີ່ມຂຶ້ນໃນອຸດົมສາຫະກິດອາກາດ ແລະ ອື່ນໆ. stamping mold ມີຜົນປະໂຫຍດຫຼາຍທີ່ເຮັດໃຫ້ມันບັນທຶກຄວາມສູญເສຍ, ມັນແມ່ນມີຄວາມສະຫງົບສະຫຼາຍ ແລະ ມີຄວາມປະຕິບັດທີ່ດີກວ່າເຄື່ອງເກົ່າ. ຕັກສະໜາ, ມີຄວາມຖັນຖິນ ແລະ ສຳເລັດການແມ່ນຄຸณລັດທີ່ດີສຳລັບຜູ້ຜະລິດທີ່ຕ້ອງການສົ່ງສິນຄ້າອອກໄປຫຼາຍກວ່າຄົນຂັງ.

ແ*</แม້ວ່ ຄວາມເรົາໄວຈະເປັນສິ່ງທີ່ຄຸນຫຼາຍໃນການຜະລິດ, ຄວາມຖືກຕ້ອງກໍ່ເປັນສິ່ງທີ່ມີຄວາມສຳຄັນຂຶ້ນ. ພິມພາບທີ່ມີໂຮງແຮມ伺服 (servo feeder presses) ກໍ່ແມ່ນການສະແດງຄວາມແຂງແຂ້ອນເຫຼົ່ານີ້. ມັນຊ່ວຍຫຼຸດຄວາມສູญເສຍແລະວັດຖຸທີ່ບໍ່ໄດ້ໃຊ້, ຂອງທີ່ສາມາດເປັນຄ່າ用用ใช້ຫຼາຍສຳລັບບໍລິສັດ. ທາງບໍລິສັດສາມາດຜະລິດອົງປະກອບທີ່ມີສະຖານະຄຸນຫຼາຍຂອງພວກເຂົາເองໂດຍໃຊ້ເຄື່ອງຈັກເຫຼົ່ານີ້. ນັ້ນເປັນການສະຫຼຸດໃຫ້ພວກເຂົາສາມາດຜະລິດສິ່ງທີ່ກ່ອນນີ້ເປັນສິ່ງທີ່ຫຍຸ່ງຫຼືເປັນພິເສດ. ດ້ວຍການເພີ່ມການຄົບຄົ້ນໃນການເຮັດESTAMPING, ບໍລິສັດສາມາດເຮັດວຽກໄດ້ເรົາໄວກວ່າແລະສຳເລັດໃນການເຊິ່ງເສີມການໃຊ້ວັດຖຸ. ຜູ້ສະແດງສຳລັບພະແນກຂັດ ສັນຍາມວ່າຈະມີເວລາພັດທະນາຫຼາຍກວ່າແລະອຸບັດຕິພັດສຸດທ້າຍຈະເຂົ້າຄືນແລະໝັນເປັນພິเศດ. ທາງເຊື່ອມໂຮງໝາຍໄດ້ເພີ່ມຄວາມສຳຄັນໃນອຸດົມສາດ, ການສົ່ງຜ່ານຄວາມສັບສົນແລະຄວາມຖືກຕ້ອງໃຫ້ກັບຜູ້ຜະລິດ. ນັ້ນແມ່ນເຫດຜົນທີ່ມັນຖືກໃຊ້ຫຼາຍໃນອຸດົມສາດຕ່າງໆ, ສະແດງໃຫ້ເຫັນວ່າເຄື່ອງຈັກເຫຼົ່ານີ້ແມ່ນການສັ້ງສູງສຸດ. ເຄື່ອງຈັກເຊື່ອແມ່ນເປັນການສັ້ງສູງສຸດໃນການຜະລິດ, ເນື່ອງຈາກວ່າມັນສາມາດເພີ່ມຄວາມສັບສົນໃນການຜະລິດ, ເນື່ອງຈາກວ່າມັນບໍ່ສັ້ງຄືນ.

ຄວາມສູມສູນໃນການຈັດການຄຸນຄ່າ, ຄວາມພົບເຫັນແລະຄວາມໜ້າສົງຂອງສິນຄ້າແລະບໍລິການແມ່ນຄົນທີ່ສຸດ. ຕົວແທນ Lihao ຂອງພວກເຮົາມີຄວາມຊ່ຽງແລະສົ່ງຜົນລະບົບທີ່ໜ້າສົງທີ່ສຸດ. ບໍລິສັດຂອງພວກເຮົາແມ່ນການອຸດมະສານທີ່ສຸດ. ພວກເຮົາໄດ້ສະແດງຄວາມສູມສູນໃນການສັ້ງສັນ, ສົ່ງຜົນສິນຄ້າທີ່ມີຄຸນຄ່າສູງແລະບໍລິການທີ່ດີທີ່ສຸດ.

Lihao Machine ກຳລັງສະໜອງວິທີການທີ່ຕັ້ງຂຶ້ນແລະບໍລິການທັງໝົດເພື່ອສັນຍາຄົນທີ່ຕ່າງກັນ. ພວກເຮົາສະໜອງບໍລິການທີ່ປະສົມປະສານທີ່ເອົາໃຈໃນການອອກແບບ, ການຜະລິດແລະການຂາຍ. ຕົວມີວິທີ R&D ທີ່ສົມບູນຈະສະໜອງທ່ານດ້ວຍວິທີທີ່ເປັນສະໜັບສະໜູນແລະການສົນທະນາເທັກນິກ ເພື່ອສັນຍາວ່າທຸກໆວິທີຈະຖືກຕັ້ງຄ່າເພື່ອສັນຍາຄົນ.

Lihao Machine ໄດ້ເປັນຜູ້ນຳໃນຊ່ວງທີ່ຂາຍມາ 26 ປີ. ມັນແມ່ນຜູ້ສະໜອງທີ່ໄດ້ຮັບຄວາມສັນໃຈທັງໃນອຸດຳແລຂອງປະເທດແລະຕ່າງປະເທດ. ສິນຄ້າຂອງພວກເຮົາໄດ້ຖືກໃຊ້ຢ່າງຫຼາຍໃນຫຼາຍອຸດຳແລທັ่ວໂລກ. ພວກເຮົາໂຫຼມລູກຄ້າທັ่ວໂລກດ້ວຍການມີສູນການຂາຍຫຼາຍກວ່າ 20 ສູນໃນຈີນແລະສູນຂາຍໃນອິນເດຍ. ພວກເຮົາໂຫຼມລະບົບທີ່ເປັນຕາມຄວາມຕ້ອງການໃນຫຼາຍອຸດຳແລດ້ວຍເທັກນົໂລຊີທີ່ມີຄວາມໜຶ່ງແຂງ.

ບໍລິສັດຂອງພວກເຮົາເປັນຜູ້ຊ່ຽວຊານດ້ານວິສະວະກຳ ແລະ ການອອກແບບທີ່ມີຄວາມແຂງແຮງສູງ, ເຊິ່ງຊ່ວຍຫຼຸດຜ່ອນການປ່ຽນແປງໃນການຕັ້ງຄ່າ ແລະ ການຜະລິດທີ່ຖືກທິ້ງເປັນຂະຫວາດ. ເຄື່ອງຈັກປ້ອນວັດຖຸດ້ວຍເຄື່ອງຂັບເຄື່ອນ Servo ຂອງພວກເຮົາມີບໍລິການຝຶກອົບຮົມ ແລະ ຕິດຕັ້ງທົ່ວໂລກ, ເພື່ອຮັບປະກັນປະສິດທິພາບສູງສຸດ ແລະ ການບູລະນາການທີ່ເປັນໄປຢ່າງລຽບງ່າຍທົ່ວທຸກບ່ອນ. ດ້ວຍທຸລະກິດການຜະລິດຂອງຕົວເອງ ແລະ ການສະໜັບສະໜູນແທ້ຈິງຂອງແທ້ຈິງທີ່ມີຄຸນນະພາບສູງ, ພວກເຮົາສາມາດຮັບປະກັນເວລາທີ່ເຄື່ອງຈັກຢຸດເຮັດວຽກຕ່ຳສຸດ ແລະ ປະສິດທິຜົນທີ່ສູງ. ບໍລິສັດຂອງພວກເຮົາໄດ້ຮັບການຮັບຮອງຕາມມາດຕະຖານ ISO9001:2000 ແລະ ໄດ້ຮັບການອະນຸມັດຈາກ EU CE.