Teknologjia e presës së stempelimit të metaleve është një mjet thjesht për formimin e pjesave metalike! Një presë stempelim metalesh është një pajisje e madhe që përdor një formë speciale për të formuar dhe larguar metal. Kjo formë aplikon presje në një lak metal për të formuar atë në një formë të caktuar. Lakja metalore kalon midis formës dhe një sipërfaqe rrafsh. Presa largohet pastaj, me forçë të rëndë, për të formuar pjesën. Kjo quhet bashkëlakim. „Oh! Është materiali që i kanë përdorur për të bërë gurte për automjetin tonë dhe edhe disa gjëra në shtepi jonë dhe edhe lojra!”

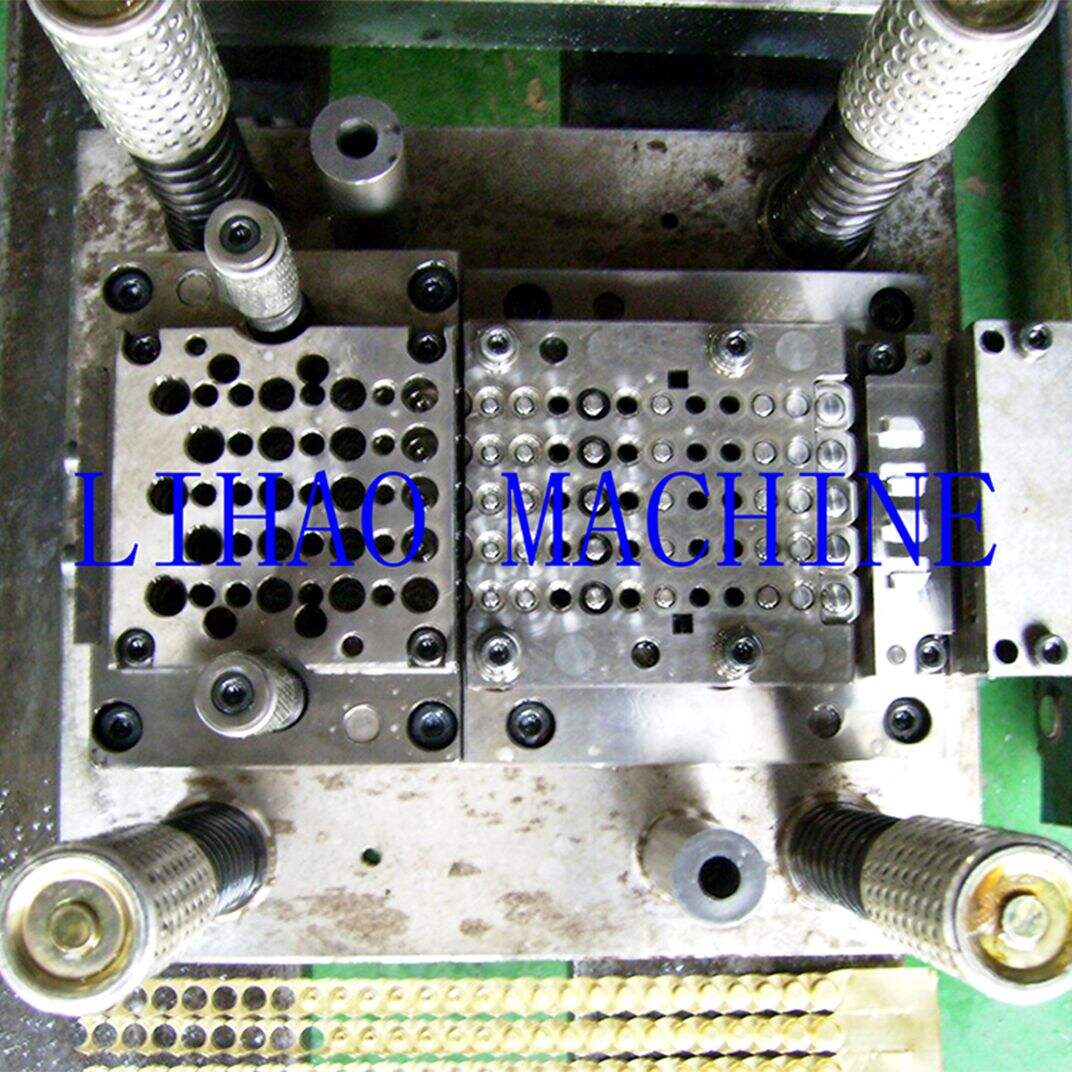

Faqet e stempelimit të metallit janë mašinat me precizion. Larg dhe larg, ata mund të bëjnë të njëjtën pjesë pa një gabim vetem. Kjo është e rëndësishme, sepse kjo do të thotë se kur gjithçka është montuar, atëherë të gjitha pjesët lidhen perfekt. Faqja e presjes është një tjetër mjete efikase. Ata mund të lëvizin shpejt dhe të prodhoshin shumë pjesë në një kohe të shkurtër. Kjo është e dobishme nëse jeni në një biznes që ka nevojë të bëjë shumë pjesë për çdo gjë që po bëni.

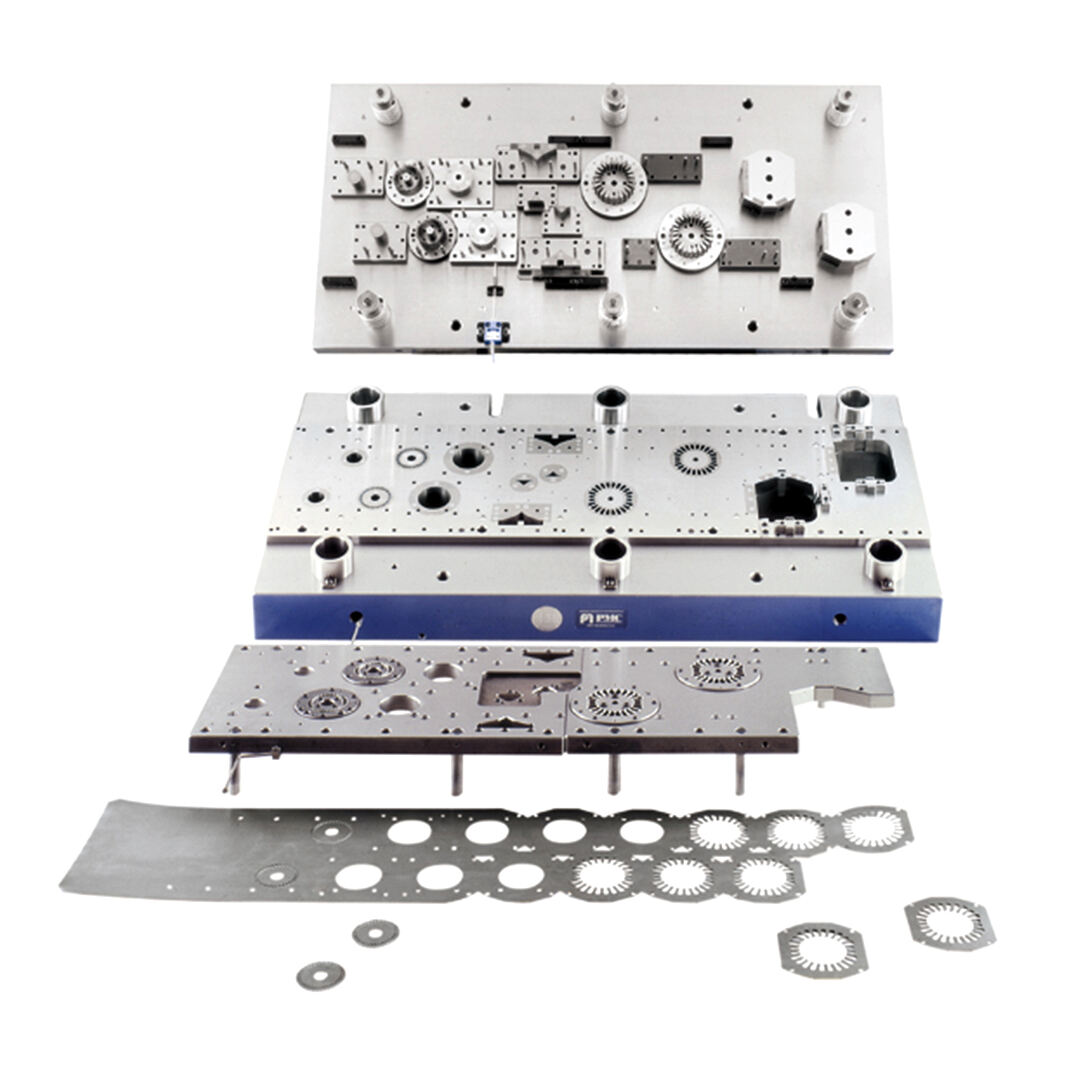

Presat e stempelimit të metaleve kanë aplikime në disa industria. Ata mund të bëjnë pjesë të thjeshta si klashe dhe shigjet, dhe gjithashtu mund të bëjnë pjesë komplekse si geara. Presat e Stempelimit të Metaleve Janë Versatile Presat e stempelimit të metaleve PARSIPPANY NJ -- (SBWIRE) -- 05/30/2019 -- A shtypje metalike është një pajisje që zgjedh sasi të madhe të forçës shejt për të thelluar ose formuar metal, midis tjera. Mund të punojnë edhe me metale të tjerë. Kjo versatilitet i ka bërë ato të parapëlqen për prodhuesit që bëjnë një varg të pjesave.

Ka disa lloje të presave të stempelimit të metaleve që kanë këto opsione avancuara për të bërë ato edhe më produktive. Për shembull, disa presa kontrollohen nga kompjuter për të lejuar operatorëve të programojnë ato për të bërë një varg të pjesave pa ndërruar formën. Kjo është një ruajtës i kohës dhe rritës produktiviteti. Presat e tjera kanë sensorë që mund të caktojnë nëse një pjesë nuk është formuar sipas drejtparshmërisë dhe mund të rregullojnë për të siguruar që çdo pjesë të jetë bërë perfekt.

Tecnologjia e presjes me punch është një objekt larg, dhe ide të reja përdorren rregullisht për të përmirësuar efikasitetin dhe kualitetin e procesit. Një ide e re dhe e erdheqshme është përdorimi i motorëve servo në presat e stempelimit të metaleve. Motorët servo janë shumë të sakta dhe kontrollueshëm, kështu që edhe pjesë më të mira mund të prodhohen. Një ide tjetër e re është përdorimi i programare simuluese që lejon prodhuesve të provojnë procese të ndryshme të stempelimit në kompjuter para se të bëjnë pjesën. Kjo minimizon humbjen dhe maksimizon produktivitetin.