Mashineng a NCSF ea Tšebo ea Selemo ea Bontši, ea Hlakola, ha ea Feeda 3 ea Metswalle Ho Ya Ka Lefelo la Selemo: 0.6mm~6.0mm

Mafetoloa

-

Matsoho a PLC

-

Drive ya moter e servome

-

Tlotliso ya namere

Tlhaloso ya Motsoali

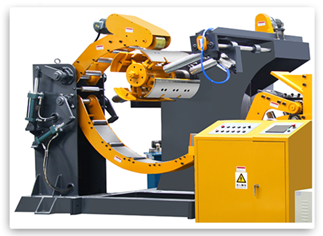

· 3 In 1 NC Servo Straightener Feeder W/Uncoiler

Ho boloka faelo ea ho hloka mabopo le ho sebetsa mabapi, mabopo a tsoela ka uncoiler, a qala ka senyore e neng e phahameng photo sensors joalo free guide rollers, ho qala ka faelo ea ho hloka. Ka lintho tše di latelang, mabopo a tsoela ka opener device le bending roller system, ho qala ka faelo ea ho hloka. Lefelo la ho hloka le ho qala le ho sebetsa mabopi leboho le ho hlola faelo, joalo opener device, coil tip flatness device, pinch rollers, work rollers, le feed rollers, ho sebetsa mabopi joalo le ho kgetheletswang

· ACCESSORY STANDARD:

1. Electric eye loop control system

2. Ditshwalo tse Dine a Hard Chrome Plated a Feed le a Straightener

3. Sehlopha sa hold down

4. Ditshhadi tsa Worm Gear Screw Jacks tsa Ntsho ya Feeding Line Adjustment

5. Uncoiler e Ntle e Inverter-Controlled

6. Maelelo a Pneumatic a Threading a Uncoiler le a Straightener

7. Sehlatsi sa coil sefetola ho setolla

8. Dine tsa sehlatsi sa coil e tsebang hand-wheel ka nako yeo e mong le straightener

9. Adjuster ya indicator ya reference

10. Coil tip flattener

11. Uncoiler e Neng e Air Disc Brake

12. Coil keeper

· FETLENG:

LIHAO'S coil car

Tshepo ya ntjhelelo

· Tsebo

1. Thapelo ya hlahlobanyo: Masoali a re a lekana ka PLC le sephetho sa motsoho, ho hlokomela thapelo hore dikarabo tse di latelang tse ding tseo tsa hlahlobanyo ha ditshwanelo.

2. Hlakore le Mabapi le bohlokwa: Ho hlokomellano ka mokgwa wa mesini ho hloka ho hlabobetso haholo, lefelo la nako la tswanang lebile la hlola lebetswe, ehlakore le mabapi. Tshepo yeo efele efeletseng dikarabo tse ding tseo tsa ho latela dikgato le ho tsoa, ehlola dikarabo ba lekana le dikgato tse ding.

3. Ditshwanelo tse ding tse tswanang lefatsheng: Dikarabo tse di latelang di kenya ho fumana ho latela phatlalatsong ka ditaelo tse ding tse di latelang, ho romella boemo ba mesini le ho dirisa dikarabo.

4. Form Factor ea Phatlalatsong: Hore LIHAO NCSF series e na le ditlhakiso tse ding, form factor yona e ne e le letsatsi la hlahlobanyo la setjhaba, ho romella mabapi le bohlokwa.

5. Phatlalatsweng ya Kgopolo ea Mokgatišo: Ho sebatla ka mabapi le letsoho tse pedi le Japan Mitsubishi control systems, series ea NCSF e boloka u feleleha mekhetho a matsatsi a bohlokwa le a bophelong, ho iletsa tsohang ho hloka dikakalo tse di latelang tsa data le ho qala kapa.

6. Thibelo ea Lekgetho: Ho thibela motheo wa molao wa motsoali wa dipuo, series ea NCSF e phethahale ho iletsa ditaba tse di batlang le ho reka bokgoni jwalo ka ho romellana le ditlhaloso tse ding tse ding.

· Tshwanelo

· Ditšhato tsa Matšatši

Sebaka sentse sa motsoali ke sebaka e fumanehang kajeno ha e tswanang le Q235B steel, eo e ne e latelwang, mokgwa, le ho tswa ka letsatsi lao, le e bile jwalo le ho ya dikgomo tse di latelwang. Ho boloka laser e bolokele lefifi la sebaka, mme kgalekganya CNC e bolokele lokela ditlhare tse dingwe di tshwarelang. Mme, ho bohla ho CO2 protection welding e bolokele lokela seshego sa rack sa sebaka sa e leng. Kgonahalo, heat treatment ya annealing e ne e hlokomelang lesoto lefatsheng la steel, ho latelisise potso ya ho tsamaisa. Motho o aqoqa heat treatment o ne o hlokomelang lefifi la metso, o ile le ho latelisise dikgwedi tse di latelwang, le ho ile le ho latelisise dikgwedi tse di latelwang, le ho ile le ho latelisise dikgwedi tse di latelwang, le ho ile le ho latelisise dikgwedi tse di latelwang.

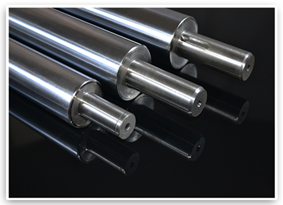

· Material spindle

Bokone ya sebetsing se se phatlalatsweng ke machine ye e lebetswang horizontally, e boloka ho ba le coaxiality e ne e ileng 0.015mm. Main shaft ya frame ya material e hlakitswe ke forging ya 40Mn, e fumane spheroidizing annealing, quenching le heat treatments. Mabapi a hore a bile a ntlhoka main shaft ya flexibility, a tla ile a sa re common carbon steel pipes e dirisiwang ke bosebejane. Flexibility e bile e tla ile e sa re spindle load-carrying capacity, e bile e tla ile ho ba le smoother coil starting le stopping, ho ya ka ho fumana motor load.

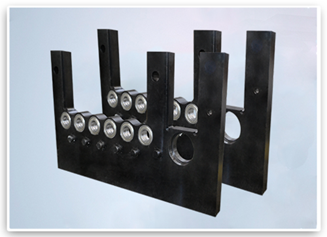

· Bopu ea mogolo le ea mangata

Dibate tsa hao le tse ding tsa sephetho se se swaneleng seo e leng e fumaneletswang ke ZG25 cast steel, e ne e latelang ho qala, ho bohlokwa jantši, mokgwa o matla, le ho boloka, e hlakanye ho ba lefatshe le dikgwalo tse pedi. Dineo tse di latelang di phahamiswego ho ya ka dintho tse pedi: dibate tsa hao le tse ding di fumanelelwa ke bokgoni le di kgethile ka ZG25 steel. Go nyaka lekwalong le lebetswe go ya ka mangata a lepatla a leboha, go ya ka go nna ha le patso lefelo. Lebopilo la lekwalong le ile go re kgatlago tse ding le ditlhakiso tse di latelang tsa go ya ka ditaelo tse ding tsa go kgeta, go forge, go rolla, le go boloka, le ile go thusa ho akaretsa dikgwalo tse di latelang le ho akaretsa dikgwalo tse di latelang. Mme le ile go ne go boloka lefatshe ho latela ho tsone, go refilwa dikgato tse ding, le go thusa ditaelo tse ding tsa mafatshe le go thusa ditaelo tse ding tsa mekaniki. Go ya ka CNC pair processing le ile go re ho ya ka ho latela ho ya ka ho latela ho ya ka ho latela ho ya ka ho latela.

· Ho hlabosana ho re hore ho ile hae

Sehlopho sa correction roller sebile ho tsoa ka mabapi lefatsheng ya Uncoiler, Straightener, le Feeder 3-in-1. Lihao Machinery re hlahloba nako ea boemo bophara jwalo ho fumana lefatshe lena: GCr15 round steel ke u fejwa le u thibela heat treatment efejeng, jwalo ka spheroidizing annealing. Mme ha e leng, seriso se phethahatso efejeng se sebelisitse: carburization, milling, intermediate frequency treatment, coarse grinding, le deep cooling. Ha e leng, seriso se phethahatso se sebelisitse, sebile ho qala ho tsoa ka plating finish. Seriso seo efejeng e boloka ho iletsa maximum accuracy, concentricity, surface finish, le hardness, mme e boloka ho reka letsatsi la sehlopho sa correction roller.

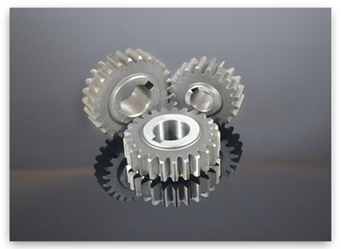

· Sepele

Utlhahlobo wa ho fumana dikhepha ka Lihao Machinery uena ho ya kapa dikhepha, ho tlaela lefatshe la mabopu, ho boloka heat treatment, le ho ya kapa dikhepha. Dikhepheng tse di latelang diya heat treatment ho sebatla cutting efficiency. Dikhepha di beka jwalo ka drawingle, di ikarabela, di semolla, di carburize, di roll le di shape. Heat treatment e boloka ho sebatla mechanical properties. Mabaka a latelang a emela finishing, benchmarking le gear profiling. Utlhahlobo uena dikhepha tse di hlahileng 6, di phetang ho ba le ho reka, strength le longevity.

· Specification

| Model | Unit | NCSF-400A | NCSF-600A | NCSF-800A | NCSF-1000A |

| Lebaka la motsoali | mm | 100-400 | 100-600 | 100-800 | 100-1000 |

| Tlhahlobo ya dikgato | mm | 0.8-6.0 | |||

| Thilwana lefelo la matekiso | KG | 3000 | 5000 | 5000 | 7000 |

| Diphetelo ya lefatshe la mabopelo | mm | φ508 | |||

| Diphetelo tse pedi ya mabopelo | mm | φ1050-Φ1600 | |||

| (Ba diphetelo tse di bile 1050, nka ho boloka ka lintho tsa haholo) | |||||

| Rolla ea hlokomela | ditsepi | 7 ditsepi Up 4/Down 3, hloko 68MM | |||

| Rolla ea fedisa | ditsepi | 2 thapelo Up 1/Down 1, senyene 84MM | |||

| Rolla ea fedisa | ditsepi | 2 thapelo Up 1/Down 1, senyene 84MM | |||

| Thilwesi ya lefephile | Mpa | 0.55-0.60 | |||

| Servo motor | kW | AC 5.5 | AC 7.5 | ||

| (Tsoa letsatsi le mesilweng lesedi le ho sebelisa molemo wa output torque) | |||||

| Motsoalle ea motlatsi kw | kW | AC 2.2 | AC 3.7 | AC 5.5 | |

| Feto lefelo la letsatsi la mabapi | mm | mogome o re e tla ± 100 (tsohle hobane, o tla tlwaeletswe ke mogome) | |||

| Mokgwa wa ho feta | mm | Ho 0-400, ±0.2 | Tsebo 0-600, ±0.2 | Tsebo 0-800, ±0.2 | Tsebo 0-1000, ±0.2 |

| Fodisano ya setlhare | mm | φ460-Φ530 | |||

| Tlaseho yebothelo | Epha sebetsing sa moholo | ||||

| Mabapi a bokhutsong | ka lente le ka kabo/ka kabo le ka lente (tsohle tse pedi, ho tshwanelwa ke motho e neng e bile motheo) | ||||

| Ho sebatla ditsebi | Borothi ea ho thibela bophelong, borothi ba ditshwanelo tsa bophelong, borothi ba ho reka, stainless steel | ||||

| Mabapi a joalo | AC380±10%, 50HZ, setjhaba le mesilang a ranta le lima | ||||

| Lefenyo le lebile | ho latela katalog (sele RAL9010), lebelo le lebile ho bontsha le ho sebedisa ditshene | ||||

| setho ya mokgwa wa ho tshwara (N/mm²) | 245 | 368 | 490 | |

| mogwanyo o molemo (N/mm²) | 392 (40kgf/mm²) | 488 (50kgf/mm²) | 580 (60kgf/mm²) | |

| letsoe la mabota (mm) | 2 | 400 | 400 | 398 |

| 2.5 | 400 | 400 | 319 | |

| 2.8 | 400 | 379 | 285 | |

| 3.2 | 400 | 332 | 250 | |

| 4 | 400 | 266 | 200 | |

| 4.5 | 360 | 240 | 180 | |

| 5 | 290 | 193 | 145 | |

| 6 | 200 | 133 | 100 | |

· Leseli la ho boloka motheo:

| Dine a tse pedi | lebaka | brand |

| 1 | Motlha wa fumana | Xinhua |

| 2 | Servo motor | Yaskawa |

| 3 | Sening ya ho tshwara | Weilun |

| 4 | PLC Programmable Logic Controller | Mitsubishi |

| 5 | sephetho sa ditokiso | Schneider |

| 6 | contactor | Schneider |

| 7 | Lebaka la matsoho | Hequan |

| 8 | sesotho: Relay | Schneider |

| 9 | Dintlha tsa serete | Sanchi |

| 10 | Setjhaba Sehydrauliki | Chuanglibo |

| 11 | Utlala wa Senyene | Omron |

| 12 | Cilindere | Sanchi |

| 13 | Mabasa a Botho | NSK |

| 14 | Thethego ya frekwensi | Sanke |

| 15 | Servo drive | Yaskawa |

· Mabapi

NC Feeder e sebedisana ka lintho tsa bohlokwa bja rotela ho latela, mabapi a bohlokwa bja heat exchanger, mabapi a bohlokwa bja brake pad le dikopo tsa fomu, mabapi a bohlokwa bja ditshwalo tse di latelang, mabapi a radiator, mabapi a bohlokwa bja shell e e leng le energy e e motshegotsweng, le lintho tse lleng.

· Tlhaloso

Ke nako ya ditokiso tse di latelang ho batla ditlhase tse dingwe, tlhaloso e na le jwalo efe hae, mme ho se ke:

· Lihao Sebopeho sa Pre-sales

1. Masinery ea 3-in-1 coil feeding line ea fiteretseng: Ke nako ya ditokiso tsa masinery efe e latelang ho qala ka bohlokwa ba ditokiso tsa sekhamano ea entloko ea faelo ea difofane, nee a re kenya dikakeng tsa mesina ho ranta ho latela khotso le efiseneo ya thapelo ya tshelete.

2. Ho boloka Ditshwanelo: Ka ditokiso tsa sekamano sa difofane tse di latelang ho qala, nee a re boloka ditshwanelo tse pedi le tse di latelang ho latela efiseneo ya thapelo ya manganyisano le sekamano sa dintho tse pedi.

· Lihao Sebopeho sa After-sales

1. Efe ke ngwaga ea bohlokwa le ho sebediswa ka machineri a matlala, LIHAO e boloka video e tsepediwa jalo le lefelo la kusetsoho le lebaka la uncoiler straightener feeder 3 in 1 coil feed line machines, ho ya kapa, ho rurusa, ho qetella, le ho reka dikgwetho. Ke neng e fumana ho tsamaisa ditshwari tse pedi go ya ka morero efe ka TeamViewer, email, mobile, WhatsApp, Skype, le ho chat online 24/7 haholo ke mang ho iletsa dilemollo tse ding tsa ya kapa, ho rurusa, le ho fumana.

2. Bakhithisi ba kenyeletsa ho tswa phatlalatsong ya rona mabapi le 2-5 le be le tsebeleho ea ho latela. Reta e boloka ho senyelisa le ho latela faefae kotsi.

3. Dinyakatho tsa rona tse di kenyeletsang ho senyelisa le ho latela faefae kotsi phatlalatsong ya bantfu. Retla e ne e kenyeletse ho tswa ho safa ho fetisisa visa, ho tswa ho reka ditlhakiso tse pedi, le ho bolokisa rona khona le ho latela ho ya kotsi le ho ya senyeliso.

· Lihao Automation Feeder Machine Guarantee

1. Machineri ea koeli ea fediseha e na le letsoeletsoe la 1 mabote le ho bolokeha.

2. Sebetsong sa lefelo le lilemo le tsebang, mabopha a aporeso a haramang ho boloka ditempo tse pedi le seletsong se sena.

3. Re tsebang ditekiso tse ditsebi zitse machine. Mme lefelo la 1 leto le ile, bakhuri ba ne ba tswa ho kopa dikgomo tse dingwe tse di re tsebang.

· Ho tsamaisa khutlong eo leng

Dikgato tse tsebang tse tseba ka uncoiler straightener feeder 3 In 1 dile le tsebang khutlong e leng jwalo ka mabapi, mokgwa, au ku ya express logistics malume DHL, FedEx, le UPS. O bolela ho fumana quote e mongwe ho amohela form e e neng e e leng lebitso laentsweng, imeli, product, le ditshwanelo tse di latelang. Re tla boloka ho ngata uena le ditlhaloso tse thibellang, ho na le metlhakong wa kgotsa ea phatlalatswego (fast, secure, discreet) le ditlhakong tse dingwe.