The core value of the 3-in-1 servo feeding machine in the automotive production line

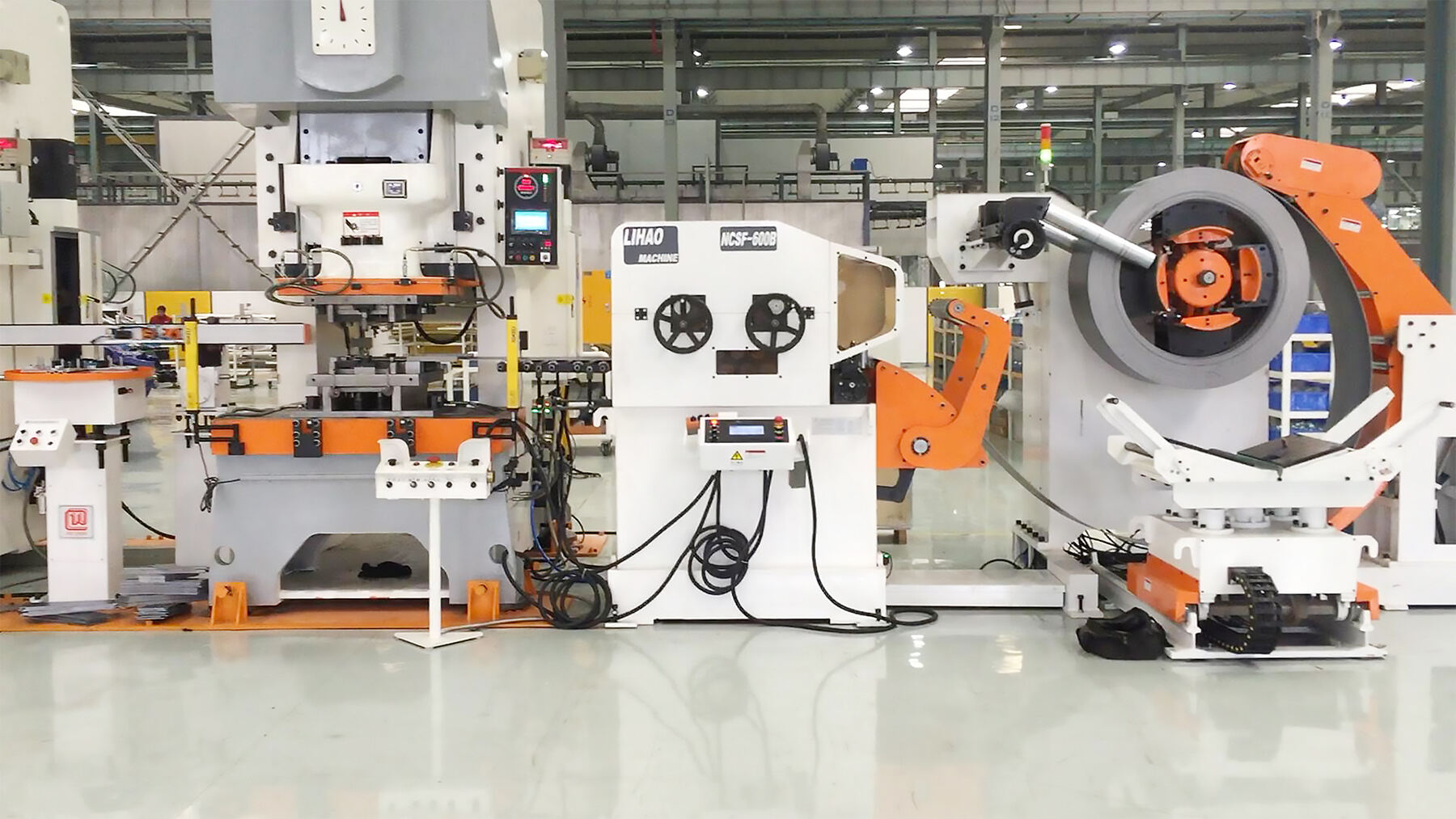

As an automated device that integrates uncoiling, Straightening, and feeding functions, the 3-in-1 servo feeder, with its compact structure, high efficiency, and precision, has become a key piece of equipment in automotive parts stamping production lines. Its core value lies in overcoming the low efficiency, poor precision, and large footprint of traditional separate equipment. It is particularly suitable for the continuous processing of metal coils such as high-strength steel and sheet metal, and is widely used in the production of automotive body structures, chassis parts, and seat accessories.

Functional Modules and Advantages of the 3-in-1 Servo Feeder in Automotive Production Lines

Three Core Functional Modules Working Together

The Material Uncoiler: A hydraulic press arm secures the coil, accommodating coils of varying diameters and widths. This ensures a stable, untied uncoiling process and a continuous supply of material for subsequent processes.

The Straightener: Utilizing multiple leveling rollers (e.g., 11) and an eccentric structure, it removes internal stress from the material, ensuring sheet flatness and meeting the stringent material precision requirements of automotive stamping.

Feeder Part: equipped with a servo control system to accurately set the feeding length, speed and pitch, achieve synchronous linkage with the punch press, and ensure the consistency of the stamping parts size.

Significant Advantages Compared to Traditional Production Methods.

| Advantages | Specific Features |

| Improved Production Efficiency | Continuous stamping speeds can reach 18 meters per minute, reducing non-productive time and significantly improving efficiency compared to single-piece processing. |

| Reduced Material Loss | Continuous coil production eliminates wasteful head and tail material, increasing raw material utilization by approximately 15%. |

| Saved Floor Space | The integrated design reduces equipment footprint by 50%, optimizing workshop layout. |

| Reduced Labor Costs | Automated operation requires only one person to monitor, reducing manual intervention and labor intensity. |

Typical Application Processes and Scenarios in an Automotive Production Line

Standardized Workflow

Equipment Preparation: Adjust the feed line height according to the punch press die height, electrically raise and lower it, and tighten the screws using the touchscreen.

Coil Uncoiler: The trolley feeds the coil into the feed rack. After being secured by the hydraulic system, limit arms and pressure rollers prevent it from spreading.

Straightening and Feeding: The coil passes through the arc guide device and enters the leveler. After multi-roller leveling, the servo system accurately feeds the coil to the punch press according to the set parameters.

Linked Stamping: Switching to automatic mode, the punch press and feeder operate synchronously to complete continuous stamping and forming, supporting multiple die switching to produce different parts.

Main Application Scenarios

Body Structural Parts: Continuously stamp high-strength steel parts such as chassis suspension and reinforcement beams to ensure dimensional accuracy and structural strength.

Precision Parts: Servo control is used to precisely process complex shapes for seat components and lifter system parts.

Multi-Process Integrated Production: Optional automatic paper collection, lamination, and waste collection mechanisms enable integrated processing from coil to finished product.

Key Technical Features Supporting Automotive Production.

High Precision and Stability

Servo Control System: Real-time adjustment of feed speed and position ensures stamped part tolerances within ±0.01mm, meeting the quality requirements of automotive safety components.

Intelligent Operation: Parameter settings and fault diagnosis are completed via the touchscreen, with support for automatic material thickness adjustment and dual-station rapid material changeover, adapting to flexible production needs.

Enhanced Safety and Reliability

Multiple Safety Devices: Equipped with photoelectric sensors and an emergency stop system, the machine reduces human contact with hazardous areas and meets automotive factory safety standards.

Durable Design: The leveling rollers are made of high-strength material, and the press arm and feed mechanism are optimized to withstand high-load continuous production environments.

Industry Trends and Future Development Directions

With the increasing use of lightweight, high-strength materials in the automotive manufacturing industry, 3-in-1 servo feeders are developing towards higher tension adaptability (such as for hot-formed steel), intelligent integration (such as integration with MES systems), and modular customization (such as dual-station uncoiling and automated scrap handling), further promoting the automation and intelligent upgrade of automotive production lines.