What is a precision punching machine?

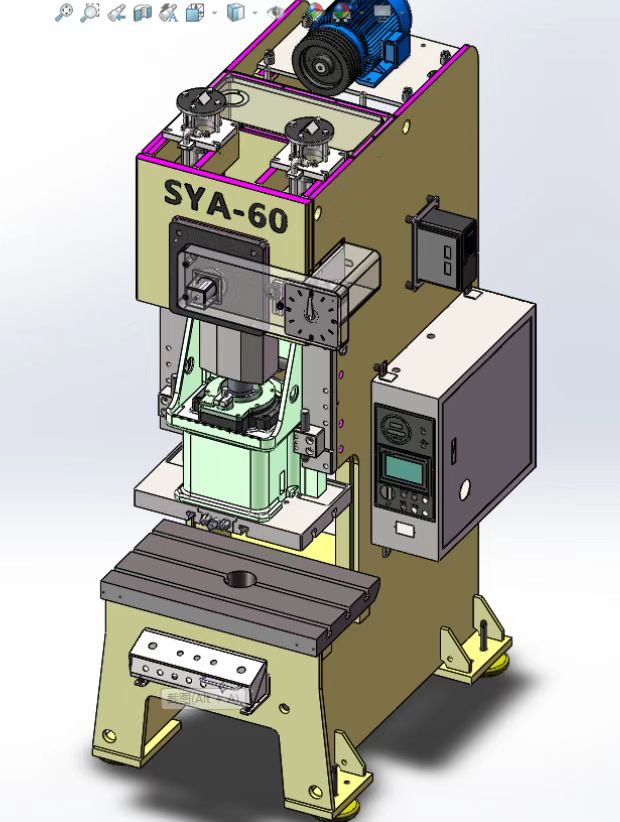

A precision punching press is a state-of-the-art forming machine designed for high-precision metal stamping. It utilizes plastic forming and cutting techniques, achieving high dimensional accuracy, smooth cutting surfaces, and the ability to create complex shapes in a single punching operation. Precision punching presses are widely used in high-volume production across a range of industries, including automotive, motorcycles, home appliances, office supplies, hand tools, hardware, electronics, and more. These presses can also be integrated with automatic feeders to facilitate automated production lines.

1. Overview

1.1 Precision Punching Press: A high-performance machine capable of high-precision forming, it uses a combination of plastic deformation and cutting techniques to produce parts with excellent dimensional accuracy and smooth surfaces in one punching step. These machines are known for their high quality, efficiency, low energy consumption, and versatility.

1.2 Quality: Precision punched parts can achieve tolerance levels as tight as T7-T8, and cutting surfaces can have a roughness as low as Rao 0.8-0.4 μm.

1.3 Efficiency: Complex parts such as gears, sprockets, and cams can be produced in just seconds using a single punching operation, significantly reducing the need for additional machining processes such as milling, grinding, or boring, increasing productivity by more than tenfold.

1.4 Low Energy Consumption: Precision punching not only saves energy compared to cutting machines, but the cold work hardening effect from the process can sometimes eliminate the need for post-punching heat treatment, thereby reducing overall energy consumption.

2. Applications

Precision punching technology is widely used across many industries, including:

2.1 Automotive: Manufacturing automotive components such as body parts, engine parts, and small precision components.

2.2 Motorcycles: Components such as frames, wheels, and other metal parts.

2.3 Home Appliances: Parts for devices like refrigerators, washing machines, and air conditioners.

2.4 Electronics: Manufacturing of metal enclosures, connectors, and other components for computing devices and electronics.

2.5 Other Industries: Textiles, agricultural machinery, measuring tools, and more.

A growing number of parts that were traditionally cast, forged, or machined are now being made using precision punching or hybrid processes.

3. Key Advantages of Precision Punching Press

When compared to conventional punching presses, precision punching presses offer several distinct advantages:

3.1 Space-Efficient: The footprint of a precision punching press is only half that of a traditional punching press of the same tonnage, significantly saving space and improving factory layout utilization.

3.2 Energy-Efficient: The total power consumption of a precision punching press is only 14KW, compared to 30KW for a traditional punching press, leading to significant energy savings.

3.3 Low Noise: Precision punching presses operate at a much lower noise level than traditional presses, making them environmentally friendly and suitable for longer operating hours.

3.4 Single-Operation Forming: Unlike conventional punching presses that may require additional processing steps, precision punching presses form parts in a single operation.

3.5 High Speed: Precision punching presses can achieve speeds of up to 30 strokes per minute, with adjustable speeds to suit production requirements.

3.6 Flexible Operations: Precision punching presses support various modes of operation, including point operation, single-cycle, and full-automatic cycles. The stroke and punching cycle can be adjusted to meet the needs of specific products, offering greater operational flexibility compared to traditional punching presses.

4. Types of Precision Punching Presses

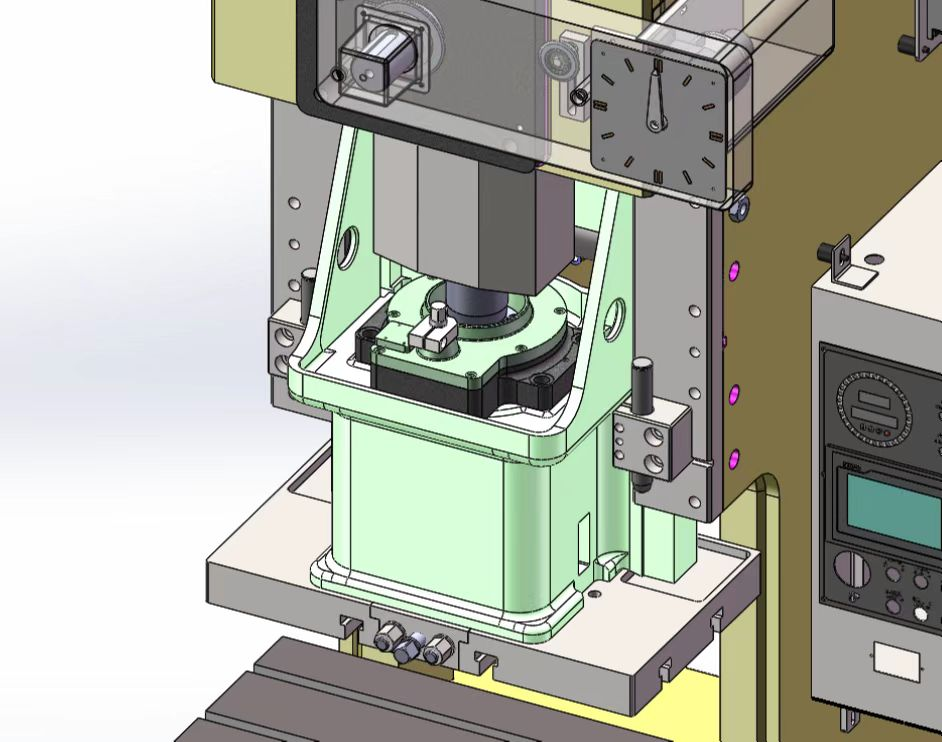

4.1 Crank Press: The most common type, using a crankshaft mechanism. It is suitable for a wide range of processes such as cutting, bending, drawing, and forging.

4.2 Crankless Press: Also known as the eccentric gear press, this type has better axial rigidity and lubrication compared to the crank press, though it comes at a higher price. It is ideal for longer stroke applications.

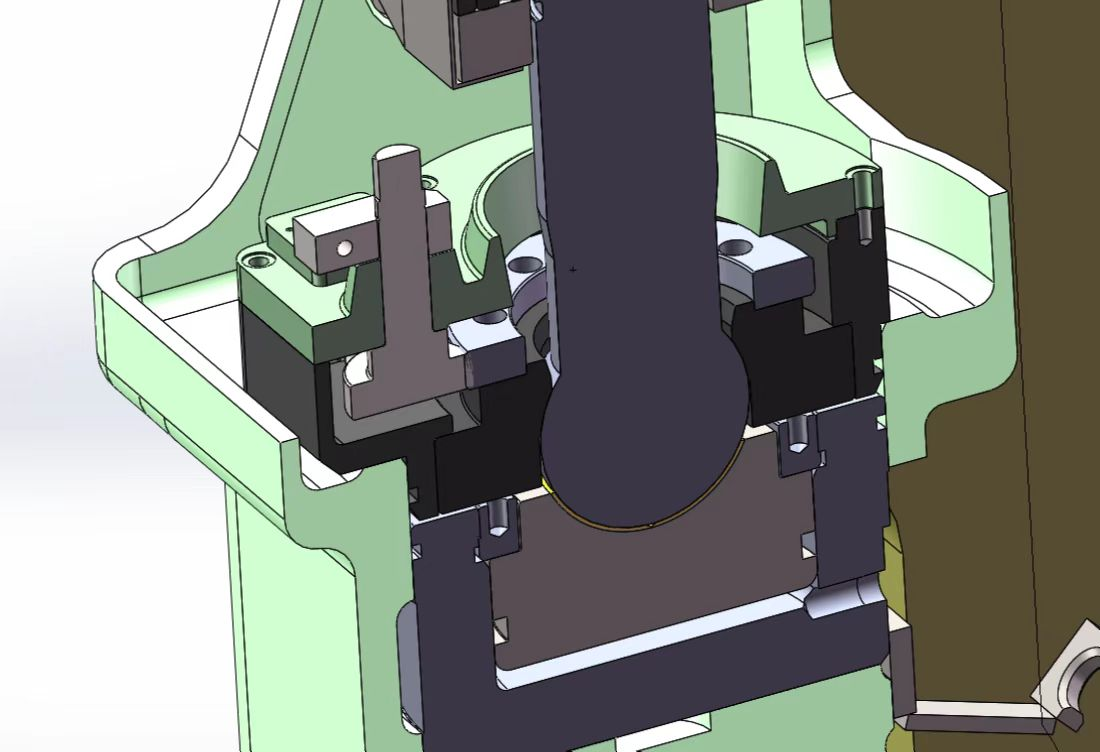

4.3 Knuckle Press: Uses a knuckle joint mechanism, providing slower speed near the bottom dead center, making it ideal for compression processes like stamping and fine finishing, particularly in cold forging.

4.4 Friction Press: Uses friction transmission and a spiral mechanism. While versatile, friction presses are being phased out due to lower accuracy and slower production speeds.

4.5 Screw Press: Driven by a screw mechanism, commonly used for specific tasks requiring high precision.

4.6 Rack Press: Uses a rack and pinion mechanism, similar to a hydraulic press but with a slightly different operating principle. Though previously used for operations like pressing and extrusion, it has largely been replaced by hydraulic presses.

4.7 Link Press: Features a link mechanism that allows for controlled stretching speeds and reduced cycle times, improving productivity. Commonly used in deep drawing processes for cylindrical containers.

4.8 Cam Press: Uses a cam mechanism to control the slide movement, best suited for small, low-force operations, though it has limited power and capacity.

5. Maintenance and Care

5.1 Regular Cleaning: Keep the center column, slide guideposts, and mold base free of debris to avoid damage and ensure smooth operation.

5.2 Lubrication: After one month of use, apply lubricant (e.g., grease) to the flywheel and feeder to prevent internal wear. Regular lubrication during subsequent maintenance sessions is necessary.

5.3 Oil Change: Change the circulating oil within the machine after one month of use, and then every six months thereafter to maintain precision and smooth operation.