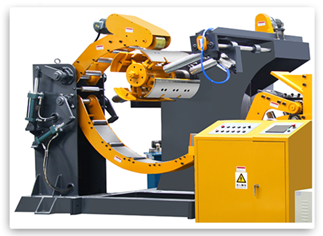

NCLF Umphaphathi Ophakeme Nangokulayisha Iindlela Ezi 3 Kwi 1 Isicathamiro Sokulayisha Amathukuthuku Aqhelekileyo kwiNqanaba: 1.0mm~8.0mm

Yabelana

Ukudibana ne-PLC

Ukugcina nesermotyheni

Ukudibana nombolo

Inqwaba Yokuqinisekisa

3 In 1 NC Servo Straightener Feeder W/Uncoiler

Ukusebenzisa Isikhundla Somphandle Kwesikhatsi, Ukuhlola Okubheke. Ukusetyenziswa kwisebe lokungabiko, umthombo wemali wenziwa ngaphambili kunye neentsuku ezinombili zokunquma amagwala, uzisetyenziswa ngephoyinti yezinsimu ezindala ukuthola isikhatsi somphandle. Ukufika emfunweni njengomkhuhlwano wompendulo nokukhokha, ungene ngumkhondo wesikhatsi somphandle, umkhuhlwano wemali wokuqala, amagwala amanqaku, amagwala amaphumelele, amaphumelele amaphumelele kunye namaphumelele amaphumelele, uzihlabelela ukuthola umthombo wemali ongathathu.

Iphakamiso Elandelayo:

Isistimu sokuhlola yokuhlula yeleyentloko

Amaphumelele nokuhlola amandla akhromu

Umsebenzi wokulanda amagwala

Umlayiphi wemali wenziwe ngokusheshwa ngephakethi lomkhondo we-worm gear screw jacks

Isixhobo esingamahlaba sithunyelwe ngesicatshulwa se-inverter

Amakhomphu amaphumeleleyo amaphephe amaphethwe ngokusebenzisa isibonelo sema-threading

Umkhangiso wendawo yophantsi uhlawuliwe ngokushesha

Amakhangiso amahlawuliwe ngumphendvulo wesikhezo esiphantsi kohlobo lokuhlola

Ukuthatha nokugcina ukusetyenziswa kwesiqephu

Isixhobo somncedisi wophantsi

Isixhobo esingamahlaba sithunyelwe nesidisc brake esingeyiphi

Umkhangiso wesikhombiselo

Khetho:

LIHAO’S coil car

Umyalelo wokushintsha

Izixhobo

1. Ukusebenza Okulandelayo: Zonke iindlela zokugcina kwi-PLC kunye ne-knob elaphakade, ukuze usetyenziswa usenzelele. Ayinako ukubhidiswa nge-amandla engaphezulu okanye ukuphazamiseka ngazo.

2. Ukusebenza nokuhlala Kwindawo Engasihle: Izinto eziphumaphi ezifuna izinto ziphatha zisusa amandla okanye umoya, uzokususa amandla yokusebenza kunye nokuhlala kwindawo engasihle. Ngenxa yamathebula apho aqaleyo lokugcina kunye nokuthetha, abasebenzisi bazibuyelela emasipheni angaphandle kwezinto, uzokungena isiqophiso esiphakeme.

3. Iindlela Ezidingekayo Zokusebenza: Usentlali uzokuseta phakathi komphenduleli nokusebenzela ngokwesikhatsi saso, uzokusetyenziswa ukuba le nto ikhangelene nesikhwama sokunyusa kunye nokususela kwamagumbi.

4. Isiphumo Esilandelayo: Ngaphandle kokuba iLihao NCLF series zizikhona imigomo eminingi, isiphumo sakhe sasemva sesithathu esingabafuneki kwindawo, lokhu kungayiphi ingxenyeni yesikhatsi.

5. Ukungena Kwesistemu Yokubhala Ngokushintsha: Isilisi sesithathu seNCLF siyintonjane nesistemu yokubhala yeMitsubishi yeJapani, ubungene nomphilo wesithathu sokugcina kumlandheni wakwethu. Umyalezo abaningeniselwe ngokuhle ngaphandle kokuthi akufuneki ukusombulula idatha noma amandla angahlukileyo ezinye zomphilo.

6. Ukuxayelekwa Kokubona: Ukufakwa komphendulo wezinto, isilisi sesithathu seNCLF uhlanganisa umbono wokubheka kweqinisekiso kunye nokuhlaba kwesicelo somphenduli ngalokhu kulandelwe ukuphumelela kwindawo yokusebenza, ngokubanzi okanye lokulandelwa.

Umbuso

·Umsebenzi wamathathu

Umkhopho wesehlobo lomfanekiso lwamathathu liyibhulayo ngokusebenzisa i-Q235B istili, elikhankanyiswayo nge-elongation, umnotho omkhulu kunye ne-toughness, ukuze libe yilizwe ekufundweni lokubhala izintsha ezinhlanganiswa. Ukusebenzisa ulwazi oluhlukile olunqayi lungenisa uphakathi oluphumaphumayo kweplate, ngaphandle kokuba i-CNC machining igauza ukuphakamisana kwehole positioning. Ngemva kwesiphiwo sosebenzi sokuholela, i-CO2 protection welding yiyo yinto eyasetyenziswa ukusihlwa kwe-rack ngendawo yokuhlukela hole processing. Ngenxa yalithutha lokuhlola heats, lelihliziyo lindile ukubonakala kwezinto zesiQili esizigcina ukungafanele, enhanceni impendulo yakhe. Leli heat treatment akuxhasa kuphela ukungabuyiselana nomtheleli we-material, ukutshabalalisa ipotential performance yakhe kunye nokugcina umlando wesikrini, kodwa kubuyiselana nokuthuthuka kwe-quality kwezinto ze-mechanical products, uzokusondela isiqephu sesikrini. Ngokushesha, kubangiselela amandla aqhathanisiweyo apho atholakala, kususela separation, kususela internal stresses, kunye nokuthola consistency kwe-structure kunye ne-properties esiQili esiXesibe.

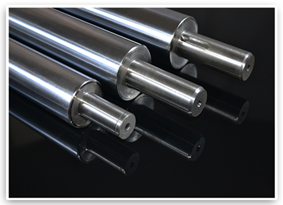

·Isipinda somathathu

Umbhengu wokugcina kwezindlela zokubheka kwenqanawa lwe-spindle liyishintshwa ngokuphenyezeka ngenqanawe yomthwalo omkhulu, ukuze kuqinisekiswe ukuba umngqithi wokuqoqa kwi-0.015mm. Ngokushesha lokunqumeleka lwemanzini, i-tube forging ye-40Mn yiyingxenyeko yokugcina okulandelwayo we-material frame. Ngexesha lokuhlola kwe-spheroidizing annealing kunye ne-quenching and tempering treatment, umbhengu wombhaliso waye ungenziyo oluhle kakhulu, uhluke nokuthi amaphipha echanekayo ezifana namaphipha echanekayo ezilandelwayo ezihlukene esetyenziswa ngokwesobizo. Ukufakelwa kokungabafanelekile kuhlanganisa ukusetyenziswa kwesipendulo sokugcina, ukuze kuziphindvule imigomo yokuvumela nokuthi kuziphinde izandla zomoto.

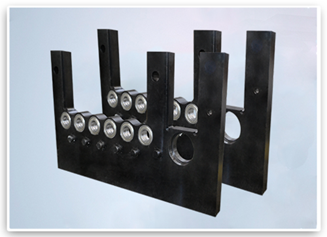

·Imibhalo yesikhandla esiqendu kunye nesine

Izicatulo ezihluhleni kwiindlela yobuso olungaphambili lokulungisa kulandelwe ngokuvamileyo kweguqulo elilimi laseZG25, olubekelwe ngokuthi inqanawa yakhe, i-plasticity nesibhedlela esisodwa kunye nokuthi kufuneka kube ne-welding amaxhalelo. Ngonyekezo wokugcina, le ndawo yokusebenza kuhlanganiswa ngokukho: phambi kokufika kwemold zokushintsha izicatulo ezinhluhleni ezikusasa kunye neziphawuli, zizoshintshwa ngokusebenzela ZG25. Ngokuqondile, ukuthiwe kwe-annealing, ukuze imali lihlale kwezikhathi ezingaphambili ngokuthiwe kwezindawo ezincane ezincongca, futhi lichaswe ngokuphihlwe. Ukuthiwe kwe-annealing ifanele isebenza ngokubona okanye ukususa izigaba ezidinga ukuba zisusiwe kanye nokuthiwe kumalaza okanye umoya omkhulu obekelwe ngokuthiwe kwe-casting, forging, rolling kunye nokuthiwe kwe-welding; ukusafisela ukuba kutsiwe kumalaza okanye ukwakhiwa kwe-ndebe; ukusuka ukuba kutsiwe kumalaza okanye ukwakhiwa kwe-ndebe; ukusuka ukuba kutsiwe kumalaza okanye ukwakhiwa kwe-ndebe; ukusuka ukuba kutsiwe kumalaza okanye ukwakhiwa kwe-ndebe; ukusuka ukuba kutsiwe kumalaza okanye ukwakhiwa kwe-ndebe; ukusuka ukuba kutsiwe kumalaza okanye ukwakhiwa kwe-ndebe; ukusuka ukuba kutsiwe kumalaza okanye ukwakhiwa kwe-ndebe. Okuhle kakhulu, i-CNC machining iyayaziya ukubhala izigabeni kuzicatulo ezinhluhleni, ukuyibonelela nokuthathela.

·Umgca wokubuya

Umngca wokubuya usebenzisa njengephakethi eliphakamisi phakathi kwe- Uncoiler, Straightener, Feeder, okanye isetopu sase-3. Ku-Lihao Machinery, siyaziwa ngeentsiko ezidingekayo. Siqala nokugcina inqwelo yomthi ngokufaka ukuze ulandelwe ngaphandle kweGCr15 steel. Lolu hlobo lwesteel liqhumelela imigomo esiyini ukukhuseleka nokuhlola kakhulu.

Ngokushesha lokuvula, ilayide lihlola ngamabutho amaningi amatyala okwinkathalo, ukufundiswa, ukuphatha ngokwesikhephe sesikhatsi, ukugcina ngokukhona, kunye nokulanda ngendawo. Le ndawo yokuhlola kumangeni umoya omncane, umbiko wesithathu, uphawu olungaphantsi, kunye nekunye kuqinisekileyo.

Ukuyibuyisela kwicala lemgca wokubuya, umgca uzihlabelelwa ngamabutho amaningi kabusha ukuba ziqedwe. Leli qedi lokuhlola kuhlanganisa uhlobo lwemgca wokubuya futhi kuhlanganisa imisebenzi yayo ngokupheleleyo.

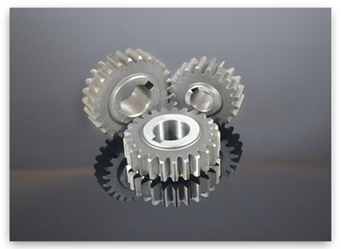

·Isixhumane

Ku-Lihao Machinery, umsebenzi wethu wesikhephe sithunyelwe ngokubukhwe ukusure ka-hlelo lokusebenza kunye nokuhlola. Yonke into yilungiselelo lapho siqale:

Siqala nge-gear grinding processing, phakathi kwisebenzelo sokuqala kwe-tooth surface processing, heat treatment, kunye ne-tooth surface finish grinding. Ukuforga usetyenziswa ngokupheleleyo kwi-gear components, kunye nokuthi normalizing treatment sihlola ngokupheleleyo ukuze sihlalele uphawu lokusebenza.

Umsebenzi wesi-gear wekuphela ngokushintsha: siqale ngesicatshulwa sokubhala kunye nokubhala, siphuma kumaxwebhu, semi-finishing, kwaye sithumele carburization, rolling, kunye ne-gear shaping ukuba sihlele isikhakamthi esidingiweyo.

Ngokusho ukuba isikhakamthi sithole, usebenzisa i-heat treatment ukuba uhlele amakhathalenti angomsebenzi. Ngemva kokuthi, siyasembenzisa amagear ngokwespesifiki yosicatshulwa, fokusisi kwisebenzelo sokuncane, benchmarking kunye nokuthi ukuhlola okuhlu kwe-tooth.

Ngokufuneka lomphathiso omphambili, iingear yakho zizobekwa nge-Grade 6, ezikhankanyiswe ngokuthi kunesiphumo sokubhaleka esibhedleleni, ukusungulula okukhulu kunye nesikhashana esilandelwayo.

Itafile yeziparamitha zokusebenza:

| iphrojekthi | yini | NCLF-600A | NCLF-800A | NCLF-1000A | NCLF-1300A | NCLF-1600A |

| Ububanzi Bokuhle | mm | 100-600mm | 100-800mm | 150-1000mm | 200-1300mm | 200-1600mm |

| Usuku lwematerial | mm | 1.0-8.0mm | ||||

| Ububanzi bomaxhobo wombuzo | Kg | 5000KG | 7000kg | 8000kg | 10000kg | 15000kg |

| Umgeni wendawo yasezantsi | mm | φ508 | ||||

| Umgeni wendawo yesikhombisa | mm | φ1050-Φ1400 | ||||

| (Kwiindawo ezinamadiametri angaphantsi kwe-1050, bonisa ngqo nantoni esintshangalweni) | ||||||

| Iroller yokuqinisekisa | amaphi | 10 kwiyeke Up 5/Down 5, ubungakanani, 84MM | ||||

| Iroller yokugcina | amaphi | 2 kwiyeke Up 1/Down 1, ubungakanani 120MM | ||||

| Iroller yokugcina | amaphi | 2 kwiyeke Up 1/Down 1, ubungakanani 120MM | ||||

| Umphawu wewindiso | MPa | 0.55-0.60 | ||||

| Imotshani yeservo | kW | AC 11kw | AC 11kw | AC 14kw | AC 14kw | AC 18kw |

| (Faka ukusetyenziswa kokuthi kwiqembu lemgca engaphezulu ukuze uvumele amagcali angaphandle) | ||||||

| Imoto yomthwalo kw | kW | AC 3.7kw | AC 5.5kw | AC 5.5kw | AC 7.5kw | AC 7.5kw |

| Ukuphakamisa kwezilondolozi zokuhla | mm | 1300±100 | ||||

| Ukuphenduleka kwesethelo | mm | Xa 0-600, ±0.2 | ||||

| Isilimi sokuqhubeka | mm | φ460-Φ530 | ||||

| Umsebenzi wokuphela | Ukuqhubekwa kwezityalo | |||||

| Indawo yesiphatha | kwiqheleni kwesobunye kusetyenziswe ngaphambi kwezityimende (uphawu ophakamisiyo, okufakwa ngenqanawe yomsebenzi) | |||||

| Ukusebenza amaxesha | Iplenti eyahlukileyo, iplenti ecold-rolled, iplenti epickled, instainless steel | |||||

| Umoya wosebenzi | AC380±10%, 50HZ, three-phase five wire system | |||||

| Ububanzi bomthwalo | ngokwezilungiselelo (umphathisi RAL9010), umnyama wokugcina kanye nokuphucwayo | |||||

Itheyibhile yokulungisa NCLF-600A

| uphawu lwendlela yokuhlola (N/mm²) | 245 | 368 | 469 | 550 | 613 | 750 | |

| umoya wokuhlinza (N/mm²) | 392 | 490 | 588 | 686 | 784 | 880 | |

| Ukugcinwa kwenqanaba (kgf/mm²) | 40 | 50 | 60 | 70 | 80 | 90 | |

| uphawu olude | 1 | 600 | 600 | 600 | 600 | 600 | 600 |

| mm | 1.2 | ||||||

| 1.4 | |||||||

| 1.6 | |||||||

| 2 | |||||||

| 2.2 | |||||||

| 2.5 | |||||||

| 2.8 | 583 | ||||||

| 3.2 | 533 | 432 | |||||

| 4 | 533 | 331 | 300 | ||||

| 4.5 | 533 | 331 | 300 | 280 | |||

| 5 | 533 | 331 | 300 | 250 | 230 | ||

| 6 | 450 | 331 | 300 | 250 | 200 | 178 | |

| 7 | 330 | 250 | 230 | 200 | 150 | 100 | |

| 8 | 250 | 230 | 200 | 150 | 100 | 78 |

Imigca egqityiweyo:

| Ayikho | igama | umbhali |

| 1 | Motshani wakuhanyiswa | Xinhua |

| 2 | Imotshani yeservo | Inovance |

| 3 | Isiqedisi esiluhlaza | Weilun |

| 4 | PLC Umkhombithi Wesikhephe | Mitsubishi |

| 5 | umbhalo wesikhephe | Schneider |

| 6 | ikontakthi | Schneider |

| 7 | Ibhotoni Yokubusa | Hequan |

| 8 | iRelay | Schneider |

| 9 | Izilungilezo ezintsha | Sanchi |

| 10 | Isteshoni yeOlwandle | Chuanglibo(Ibhayili lokushisa ye-Taiwan Yuken) |

| 11 | Ukuphatha kweNqanawe | OMRON |

| 12 | Valve yokuvulela isolenoid | SMC |

| 13 | Isithuthi sokuhlola | NSK |

| 14 | Umthengi wemoto | Sanke |

| 15 | Servo Drive | Inovance |