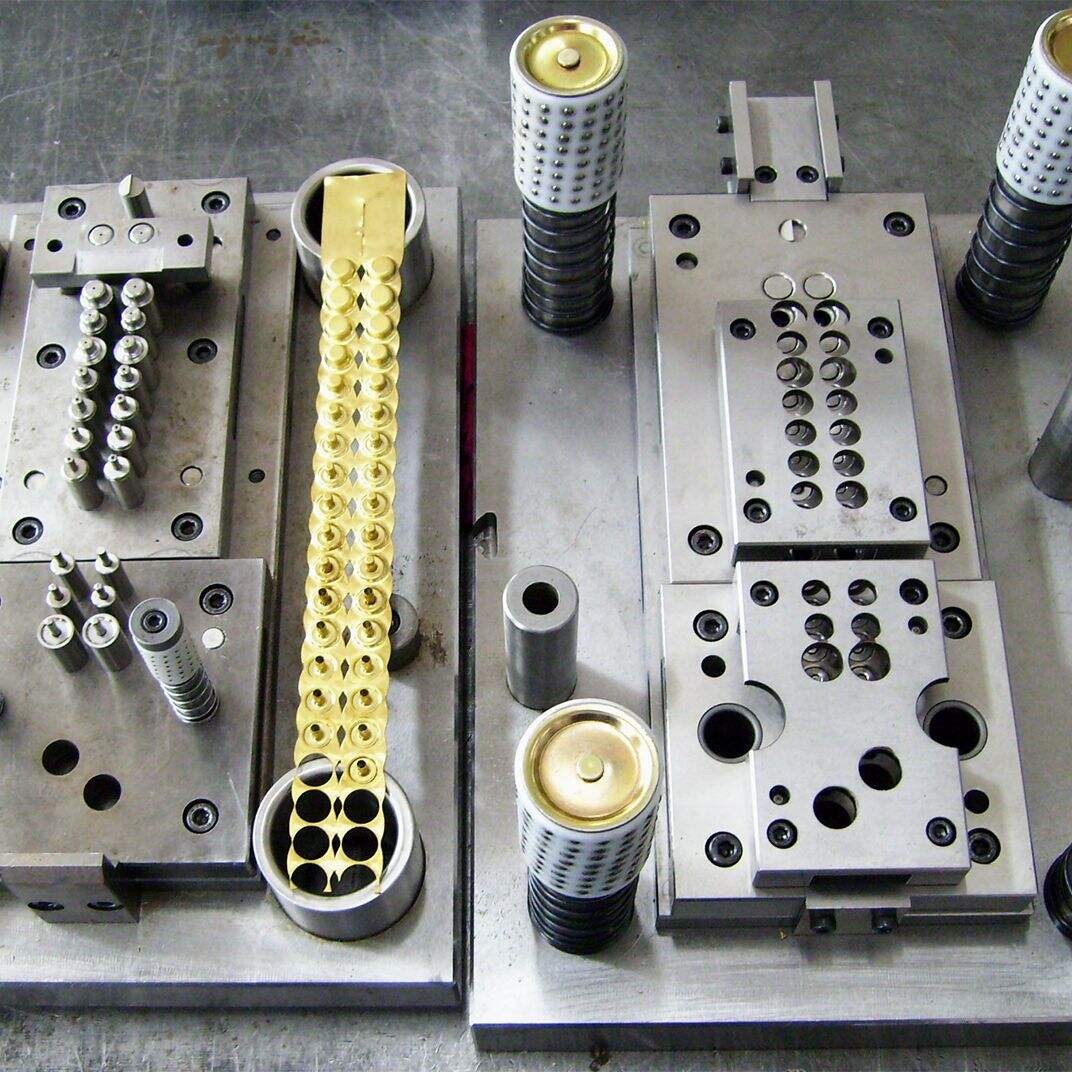

The automotive stamping dies is a unique tool used to shape metal for various parts of the car, both quickly and accurately. It acts as a gigantic metal hammer that compresses a slab of metal flat and transforms it into the proper shape. It's like a cookie cutter but for cars — it makes parts out of metal rather than dough. Lihao automotive stamping press is one of the better machines in the car-making industry. It is one of the most reliable and most advanced.

In the days before the automotive stamping press, cars were hand-made. It was a long and imprecise process for producing cars. This occasionally resulted in car parts being oversized or undersized. That increased the cost to produce vehicles, and that resulted in many who could not afford them.

The advent of the automotive stamping press changed everything in the car; Car fans can design the parts but then we need to manufacture them, and that's where it gets more complicated, with 3D printing technology this entire process is faster and more precise than making them by hand. That means higher production volumes and lower costs per vehicle. As a result, half affordable (quarter able) cars have become easier to buy and the car industry has grown much larger. A huge part of this incredible transformation is the Lihao automotive stamping press that could be making cars for the masses at your local factory before you know it.

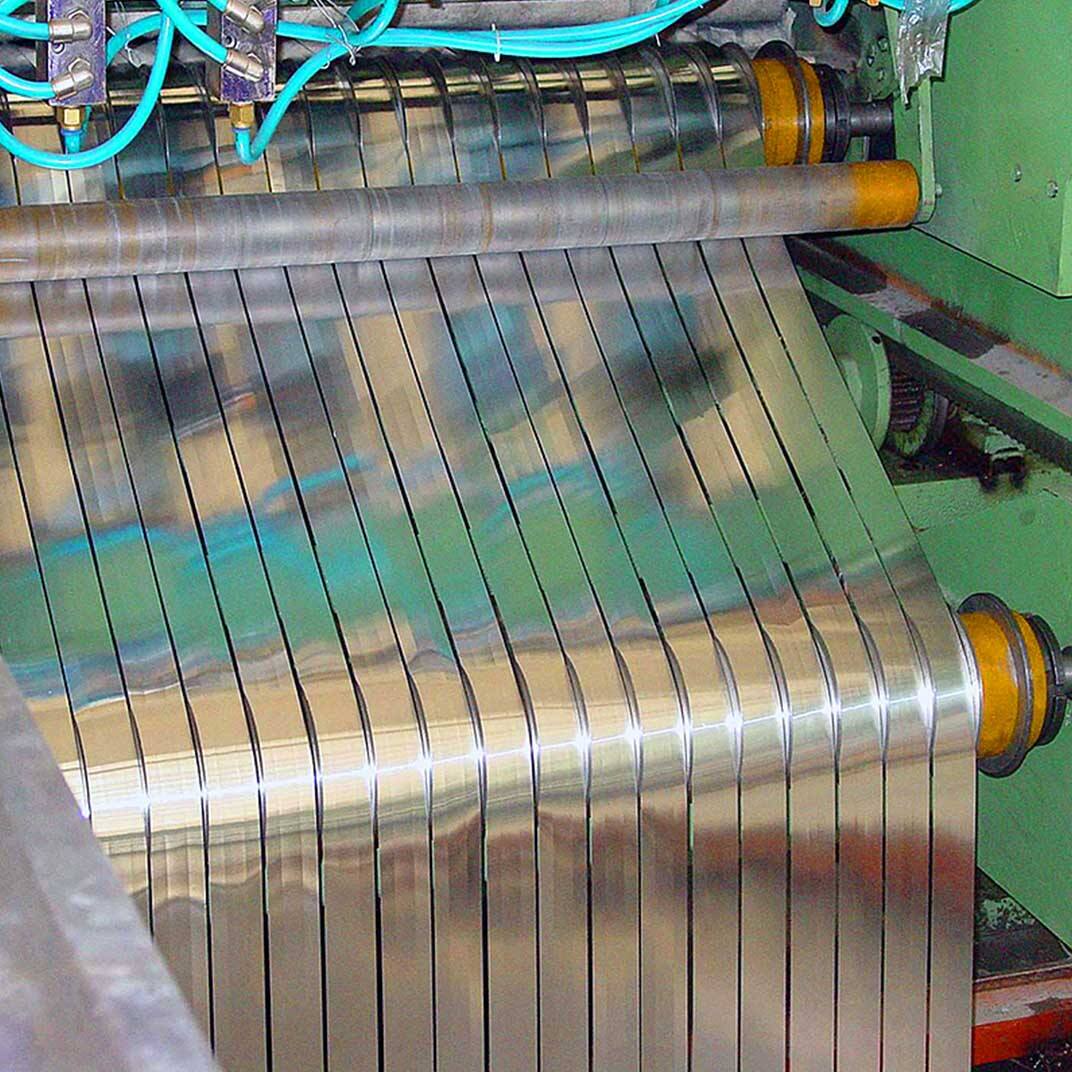

The automotive stamping press performs several duties in the manufacturing process of a car. It is used to make large components (the outer car parts, like fenders, doors and hoods) However they also produce other important components, such as door handles and brackets. Without these small parts, the car would not work properly and it makes it easier for people to use. The automotive stamping press makes car manufacturing and all its various components much easier and cheaper.

CARS NEED CARE.CARS ARE PRECISION. Cars must be assembled painstakingly properly to function effectively. If any car component is slightly larger or smaller, it can create issues with the driving of a vehicle. A door that is too small will not close all the way (this can be very dangerous) from here. That is part of the reason for producing Lihao automotive stamping press with high accuracy. In the manufacturing process, they use computer programs that ensure every part is the right size for the car. This minimizes errors, ensuring every car component is of genuine quality. Precision in manufacturing auto parts ensures better functioning and reduce responsiveness which is an important safety aspect of the car for everyone who drives.

With growing advances in technology, the automotive stamping press is improving at a rapid pace. Several new ideas and inventions are coming out that will make car parts being made simpler, quicker and help them do their function at a lower weight. Included in these concepts is artificial intelligence (AI). AI will teach the machine to learn from its mistakes over time. So the automotive stamping press can be improved through AI and learn better to perform precisely making car parts.

One intriguing fresh concept is 3D printing. It enables car makers to manufacture components, quite literally in a different form. Instead of hammering metal parts into a shape, they can print them in plastic or another material using a 3D printer. Now imagine printing out a car part instead of just any other toy from your 3D printer? So in some respects, 3D printing is a revolutionary technology for the car industry decades as powerful as the automotive stamping press. It allows for an unprecedented approach to design and fabrication.

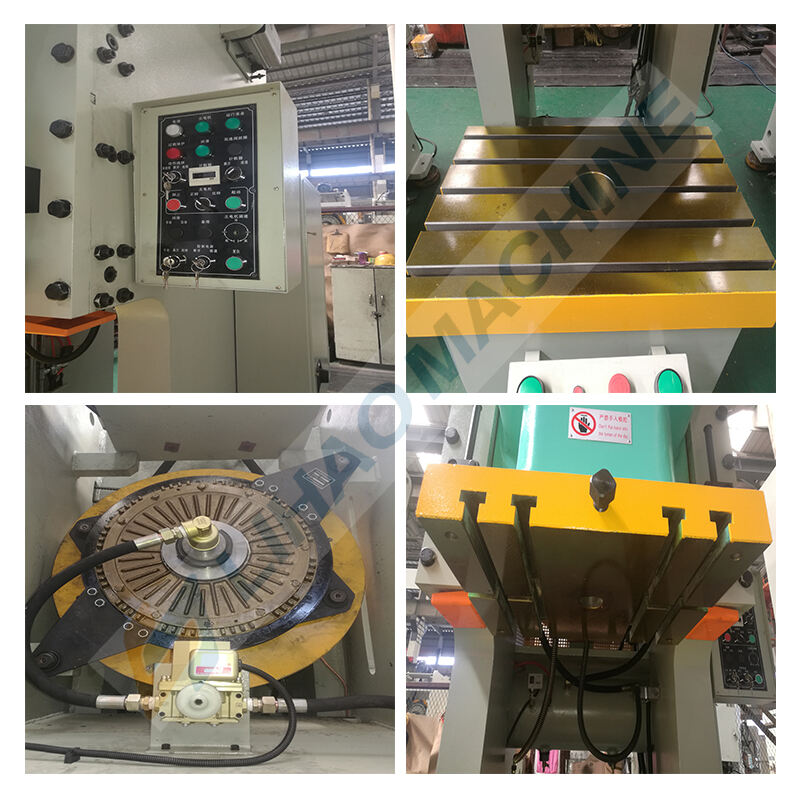

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.

Lihao Machine provides tailored solutions in addition to a complete service meet various needs of clients. We offer integrated services that encompass design, manufacturing and sales. Our R&committed D team supply you with customized options and technical conversations, ensuring that every solution is suited to your unique requirements.

We are aimed at innovation and dependability and will also be constantly expanding our services and items. Our knowledgeable Lihao team has the capacity to provide cutting-edge solutions, creating us the preferred choice equipment for stamping automation. We have been devoted to customer satisfaction, providing top-quality equipment excellent provider consistently.

Our company is experts in engineering and robust design of tools, that helps in reducing set-up adjustments and manufacturing that is scrap try reducing. Our automotive stamping press provide training and commissioning throughout the world, ensuring integration that is seamless maximised performance around the world. We confirm maximum productivity and downtime which is minimized offering manufacturing that is internal, along with high-quality spare section and service. Accredited with ISO9001:2000 and EU CE we stick to the greatest standards of quality.