Today in our life, it is impossible to go anywhere without a car. They do help you move from point A to point B, I mean they make your life easier because of transport and all. Almost close to 1000 of parts are there in the making of an automobile, have you ever imagined? There is a very crucial stage in this which is known as the stamping die. In this article, we will discuss how stamping dies are and what they mean for the automotive process.

Die Stamping Dies are special tools used in the car manufacturing process. They're stamping die essentially the templates for what turns into lots of stuff that you put together to build a car. Many vital parts such as car doors, fenders and hoods are also made from stamping dies. These Lihao are component parts used in the assembly of a car as well/content assist not working together.

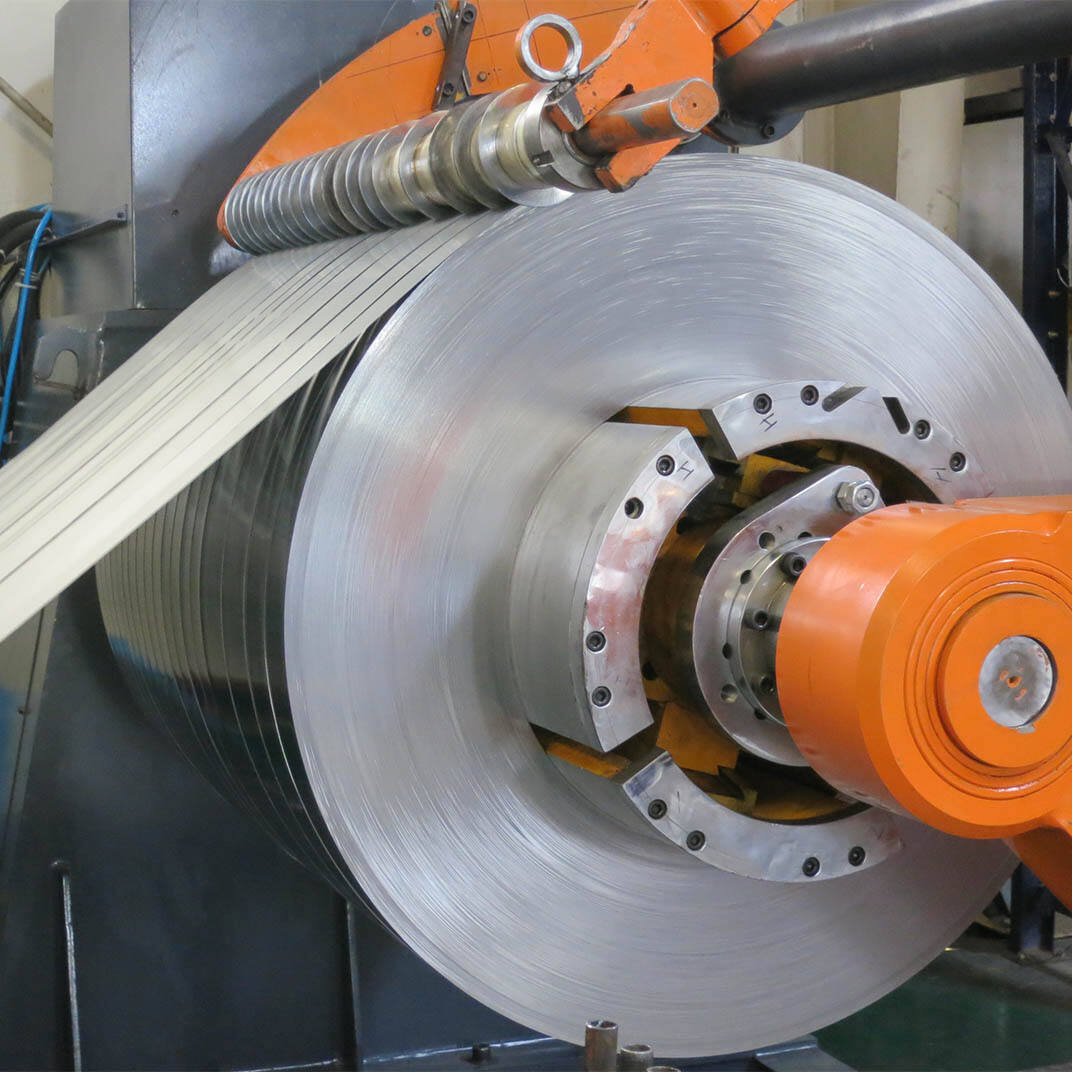

A standard universal stamping tool including the upper die, the lower die. At the start of the process, a flat sheet of metal is put in between those two pieces. After all are set in the correct place, a pressure is added to the die. The Lihao force presses, shapes and cuts the material into the exact form of the specific vehicle part. Think sandwich, but you can use cookie cutter to mould some bread in funky shapes!

For the car-making process, there are many advantages to the use of stamping dies. In the first place, stamping dies have capacity to generate very complex and accurate forms. It ensures that metal stamping dies all the car parts perfectly match while assembling it. Indeed, there is no denying the fact that it is essential to avoid poorly fitting parts when it comes to a car because they need proper replacements to have a properly functioning car and secure.

The steel stamping dies last step is production. With that step completed, the metal is stamped with a stamping die which will produce multiple metal parts at the same time. The Lihao monitoring of this process is done so that everything goes in a uniform and quality controlled way. Ensuring all these parts meet the required standards should be possible, and this is where quality control comes in.

Some of the precision stamping die other reasons stamping dies matters, is that it makes sure everything fits together correctly in every car. It is mandatory for the security and functioning of the motor vehicle. If parts of a car aren't put together right, problems can arise ranging from something as simple as breaking down or to more serious like an accident where someone is hurt. Fit is also important because it minimizes other concerns (e. g., wear, fuel efficiency).

Advancements are now made in the form of innovation and material science leading to newer technologies that help in achieving higher precision and energy-saving solutions for stamping dies. This metal stamping die includes even materials, such as carbon fiber, being used to produce lightweight and resilient car parts. Improved aerodynamics makes cars more fuel efficient and reduces harmful greenhouse gas emissions.

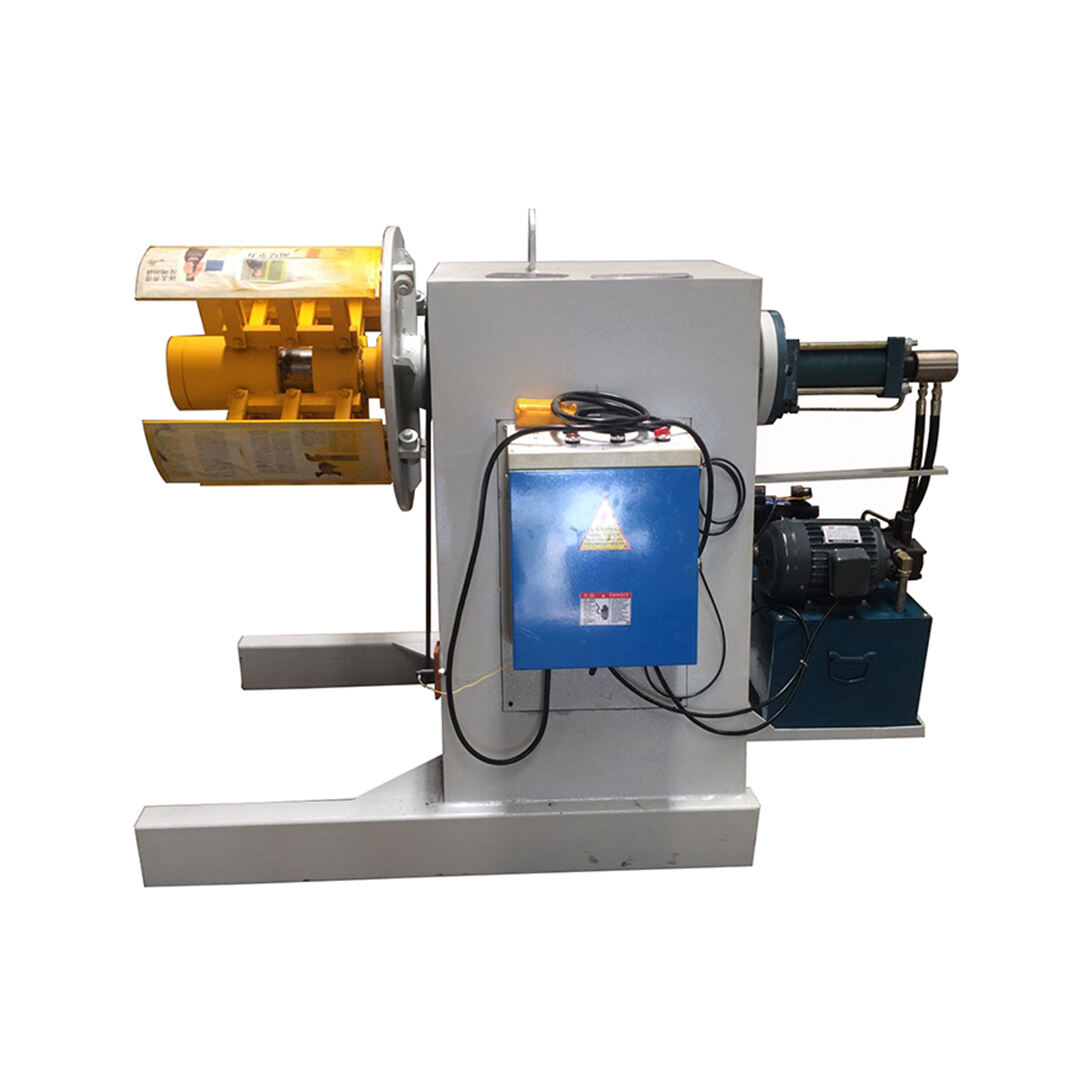

Our company is experts in engineering and robust design of tools, that helps in reducing set-up adjustments and manufacturing that is scrap try reducing. Our Automotive stamping dies provide training and commissioning throughout the world, ensuring integration that is seamless maximised performance around the world. We confirm maximum productivity and downtime which is minimized offering manufacturing that is internal, along with high-quality spare section and service. Accredited with ISO9001:2000 and EU CE we stick to the greatest standards of quality.

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.

Lihao machine has been a leader on the market since 1996. It had been a reliable supplier regarding the national and international markets. Our items are used throughout the selection of industries around the world. We offer our clients worldwide with more than 20 offices in China additionally the branch in India. Our robust technological capabilities enable customized solutions for a variety of industries.