Cut to Length Lines: The Ultimate Solution in Metal Processing

As industries around the world continue to evolve and thrive, innovation and efficiency are two key aspects that businesses must focus on to stay ahead of the competition. One of the most crucial equipment that has transformed businesses in the metal processing industry is the cut to length lines. We will delve into the advantages of these lines, how to use Lihao cut to length lines, their applications, safety, and quality and service offered to customers.

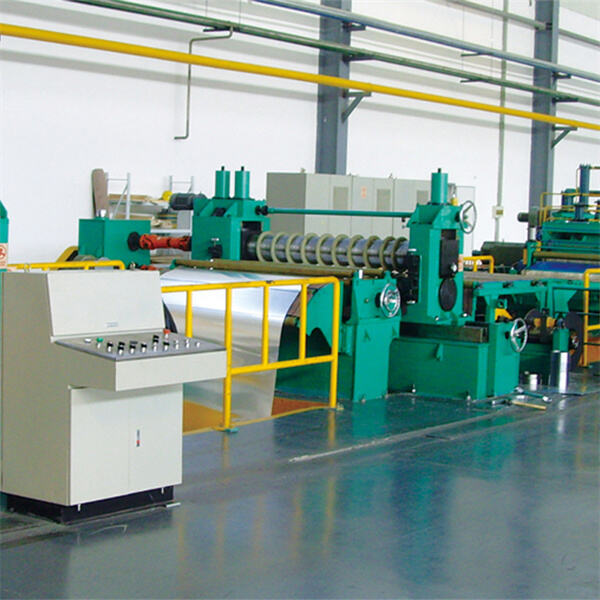

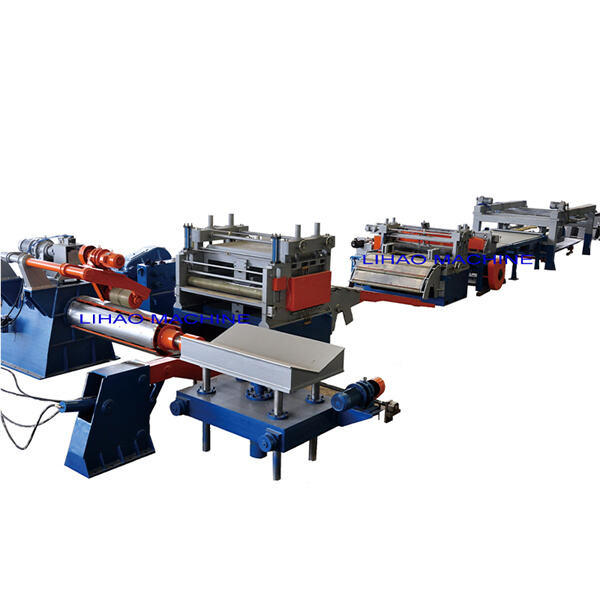

Cut to length lines are industrial machines designed to process metal sheets, cut them to precise lengths, and ensure they meet the required standards. These Lihao 3 in 1 servo feeder reduce the production time, lower labor costs, and eliminate waste production. The cut to length lines will not only improve the quality of the finished product but will also enhance the industry's safety standards.

The cut to length lines have undergone massive technological advancements over the years. The new age machines allow for faster metal sheet processing and more accurate cutting, enhancing efficiency. Additionally, most of these machines are computer-controlled, allowing for automation, and reducing the machinery's downtime. The Lihao Coil Feed Line settings also allow for customization, which ensures that the metal sheets meet the specific needs of a client's production line.

Safety is a vital aspect of any industrial activity. The line operator of the cut to length lines has to be well trained and equipped with safety gear like gloves, eye protection, and ear muffs, among others. The Lihao servo feeding line design should also have safety features like emergency stop buttons and safety guards that prevent accidents and injuries in the workplace. By adhering to all the safety standards, a cut to length line becomes not just an efficient machine, but a safe one too.

Cut to length lines find their application in several industries, including automotive, construction, aerospace, and defense, to mention a few. This versatility in application makes them an essential Lihao press feeding line in any business involved in metal processing. The machines are suitable for processing various types of metals, including aluminum, steel, brass, and copper.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our Cut to length lines offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.

And over 26 years experience in industry leadership, Lihao Machine is a supplier which was top the domestic and international markets. Our products is widely found in a wide range of. All over the world with nearly 20 offices across China because well as an overseas subsidiary India we provide our clients. We provide customized solutions in several industries, with your robust technological abilities.

Our dedication to quality, improvement and continuous reliability of products and service is a constant. Our Lihao team is extremely skilled and offers cutting-edge systems. Our company is the stamping possibility first automation. We have been focused on client satisfaction, providing top-quality products outstanding service.

Lihao Machine provides tailored solutions in addition to a complete service meet up with the varied needs of your customers. Offering a number of products like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, plus punch machines, we offer complete service that cover manufacturing, design, sales, service, and trading. Our R&devoted D team customization options and technical discussions, ensuring that every product is customized to fulfill your individual needs.