What Is a Die Stamping Press and How Does It Work?

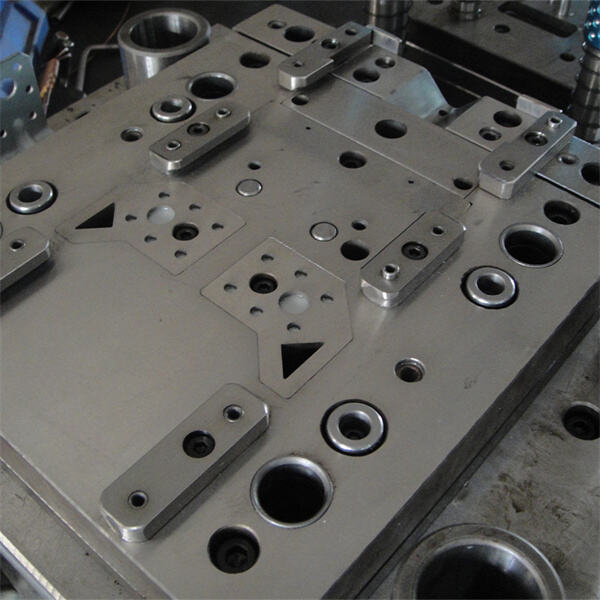

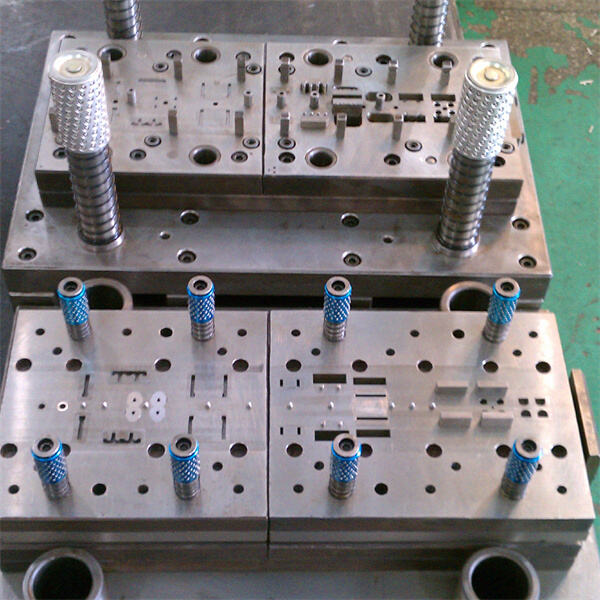

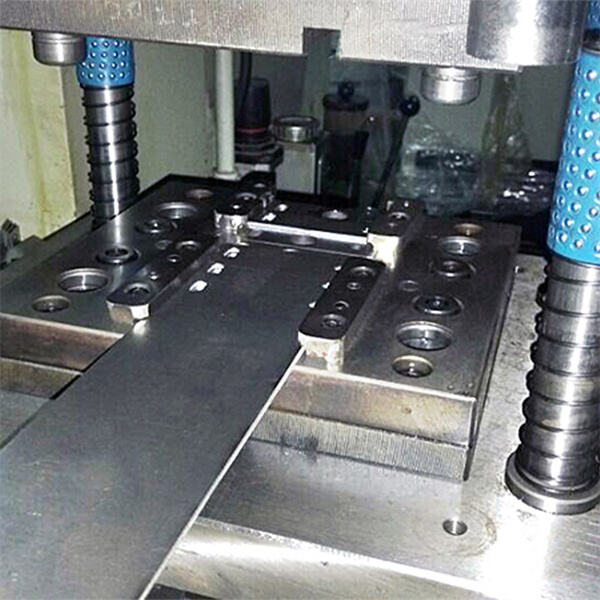

A die stamping press is a machine that uses a die to shape and form metal into a specific shape or design. The process involves the use of high-pressure force to stamp the metal into the desired shape. The metal is placed on a die, and then a punch is used to apply pressure on the metal. The force of the punch causes the metal to deform and take the shape of the die. Lihao die stamping press process is repeated until the desired shape is achieved.

Die stamping technology has several advantages over other metal forming methods. First, it offers unparalleled precision, making it ideal for creating intricate designs and complex shapes. Additionally, Lihao progressive die is highly scalable and can be used to produce large quantities of parts quickly and efficiently.

Over the years, die stamping technology has continued to evolve. Today's die stamping machines are more precise, efficient, and safe than ever before. Advances in Lihao stamping die automation have made it possible to program complex designs with ease, and intelligent sensors and cameras can monitor the manufacturing process to ensure accuracy and consistency.

While die stamping machines are generally safe to use, there are some safety considerations that must be taken into account. Operators must be properly trained and equipped with the appropriate personal protective equipment (PPE), such as gloves, goggles, and earplugs. Additionally, the Lihao progressive die stamping themselves must be properly maintained and regularly inspected to ensure that they are operating safely and efficiently.

Using a die stamping press is relatively uncomplicated. First, the Lihao metal stamping dies must prepare the metal and the die. The metal is usually cut to the desired size and shape using a shear or other cutting tool. The die is then bolted into the press, and the metal is placed on top of it. The press is activated, and the punch is used to stamp the metal into the desired shape. The process is repeated until the desired number of parts is produced.

Our company is experts in the development and design of durable tooling that can help to attenuate setup adjustments too as reduces scrap production. Our Die stamping press offering training that is worldwide commissioning, which ensures the performance which is highest and seamless integration around the world. With your very manufacturing that is own and high-quality spare parts service we guarantee minimal interruptions in addition to productivity that is highest. We are ISO9001:2000 accredited and EU CE certified.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.

we are focused on innovation and dependability, continuously updating our products and services. Our skilled Lihao team provides cutting-edge solutions helping to make us the most preferred option automation equipment found in stamping. We value customer and tend to be committed to providing top-quality equipment and exemplary solutions on a regular basis.

Lihao Machine provides tailored solutions comprehensive service meet up with the diverse needs of customers. Offering a selection of products, including 3 in 1 feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we offer incorporated services covering production design purchases, service plus trading. Our R&D team is dedicated to ensuring that the option is had by you of customizing your choices and technical discussions making sure that every solution is perfectly tailored to your requirements.

There are many companies that specialize in die stamping services. Lihao steel stamping dies companies offer a wide range of services, including design and engineering, prototyping, production, and finishing. They can work with a variety of metals, including steel, aluminum, copper, and brass, and can produce parts in a range of sizes and shapes.

Quality control is an essential aspect of the die stamping process. To ensure that parts meet the required specifications, rigorous testing and inspection must be performed at every stage of the production process. Lihao die stamping press includes testing the material strength, inspecting the part dimensions, and checking for defects or surface irregularities.

Die stamping technology is used in a variety of industries, including automotive, aerospace, electronics, and medical equipment. It is commonly used to produce parts such as brackets, housings, panels, and connectors. die stamping is also used to produce decorative items such as jewelry and metal art.

die stamping technology offers several advantages over other metal forming methods. Its precision, scalability, and efficiency make it an ideal choice for producing a wide range of parts and products. Additionally, Lihao coil handling equipment in die stamping technology continue to make the process safer, more automated, and more precise. With the help of die stamping services, companies can produce high-quality parts that meet the strictest specifications and requirements.