Have you ever wondered how they create those metal strips? It’s called slitting! A Metal coil slitting machine is a specific type of machine that is used for metal strip production. This machine has great significance in factories where metal products are manufactured. We will get more details of how this machine works, with our buddy Lihao!

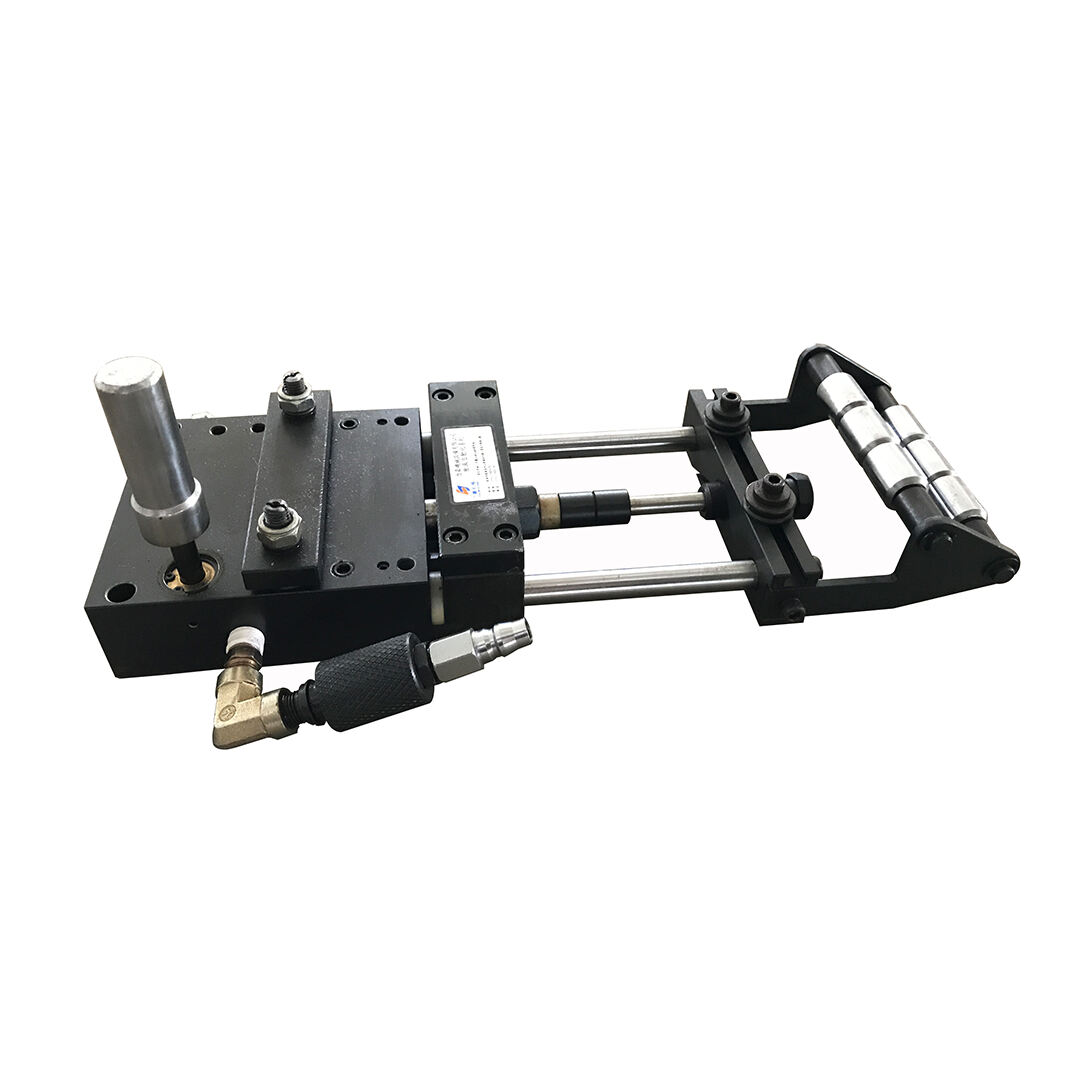

There are sizes of metal strips, and getting them right is the most important. They will not work with the products if the strips are not of appropriate size. This is precisely where a metal coil feeder comes to the rescue! It receives large metal rolls, also known as coils, and shears them into small, accurate width pieces. The machine has a blade which is like a sharp knife which cuts the base metal neatly and shortly. It indicates that the machine can cut metal without harming it. This is why the machine enables metal strips to be made which are used in many items from cans for your drinks and car parts, to airplanes that fly at very high altitudes!

It takes long and it can be exhausting to do metal coil cuts manually! Trying to slice a large roll of metal with a conventional blade – Big Metal Roll 100-3000 an Aela Puras Un from 2023 is like using a pocket knife! Not easy, and it could take a lifetime! This is why factories must have advanced slitting technology. This Metal Coil Slitting Machine slices the coils in no time with minimal effort, saving a great deal of time. And, thanks to its computer controls, the machine can ensure it is operating properly. Before it cuts the metal, it can make adjustments to cut precisely where neccessary. This makes it way much easier, quicker and precise than doing it manually and accelerates the entire manufacturing process.

Metal strips aren't all the same! Strips around different products require variable width and shapes. It could be a different size than, say, a car part would need for example, and vice versa. Novel specifications can be customized for the sheet metal feeders. In other words, the machine can adjust its parameters to produce metal bands with a configuration suitable for the planned application. There are different types of blades & spacers, along with guides that can help you take the perfect slice each time. In this fashion, the metal strips are customized for their individual applications so as to perform properly in the finished goods.

Incredibly flexibility: A metal coil slitting machine can be used with different types of metals. That is not the only kind! Aluminium, Copper and even steel are super easy to cut through the machine. All of these metals have unique characteristics and applications. It can also handle coils of varying dimensions and weight. That versatility allows the machine to perform numerous manufacturing projects, enabling factories to make a multitude of metal goods.

Waste, even a little metal is a metal. Companies obviously want to use as much material as they can so that work is not wasted and money used unnecessarily. This, in turn, reduces scrap metal waste by allowing the machine to cut coils at a lower cost. When the material to be processed is cut, less waste is left over. This also questioned inventory management and profit. The cuts are more precise, leading to less waste and a clever use of factory resources. It is entirely a game of profit maximisation while auguring caution on the scale of impact.

Lihao Machine provides tailored solutions also as a complete service meet up with the various needs of customers. You can expect integrated solutions which cover design, production and sales. Our R&committed D team provide you with customized choices and technical discussions making sure each option would be suited to your unique criteria.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.

Lihao Machine is a huge business is leading the industry because 1996. It is only a trusted supplier both the national and international markets. Our products are trusted in lots of industries throughout the world. All over the globe with over twenty offices in China and an overseas branch in Asia We provide our customers. We offer tailored solutions throughout various industries with this robust technological capabilities.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our metal coil slitting machine offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.