Metal Hole Punch Machines: A Handy Tool for Making Holes in Metal

Having a metal hole punching machine in your workshop is great if you like to play around with metals. They are machines that you can use to create accurate holes through varying thicknesses of metal sheets, allowing for faster production of ventilation (vent) holes, wiring/cables ducts or installation tabs with professional-quality finish and precision.

The metal hole punching machines that you can specifically opt for have two main types - manual and hydraulic. With manual machines, you must exert effort to punch the hole. With hydraulic drive mechanisms a smooth bore hole is achieved using high pressure against forces up to manufacturing pressures of 3OOObar that can be used for working; efficient and quiet-running as well atvariouscardinal loctions down on two disassembly lines where all accessory workplace processes are needful/UIKitorer Needed].

There are different types of manual metal hole punching machines but thehand held punch and bench top punchesare by farthe most common. The hand held punch, on the other side is designed to be used by hobbyists and DIYers who might need a complex holeor two while bench top units are more apt for larger production in industrial capacity.

When it comes to heavier metalworking projects, hydraulic metal hole punching machines are the preferred choice. With the power and efficiency that these machines boast, they are suited perfectly for industrial workshop applications as well as widespread use in metal fabrication. They include different features such as adjustable stroke depth, automatic lubrication and several punching heads.

It is a Greenlee Slug Buster: Slugged buster, 4- inch diameter in mild steel and also other materials like aluminum fiberglass etc.

Hougen-Ogura HMD904S Magnetic Drill: It is a hydraulic metal hole punching machine and this tool can create holes up to 1-1/2 inches which makes it suitable for industrial workshops.

Roper Whitney Pexto 625B Punch: This bench-top punching machine can produce holes that are as large as 1-1/4 inches in diameter, and it is compatible with mild steel, aluminum and plastic materials.

Baileigh Ironworker SW-50: This hydraulic ironworker can handle a variety of jobs, including punching holes as large as 1 inch in diameter and tasks like shearing, notching, and bending metal sheet.

Metabo MAG 50 Magnetic Drill -a manual magnetic drill to make holes up to 2 in steel and stainless materials

Metal hole punching machines are very important in the metalworking area and they meet demands of both steel fabricators and common people. Both of these machines aid in the generation of accurate holes quickly, which is why they are perfect for everything from ventilation and wiring to mounting steel parts. They also provide speed and cost savings, with faster hole-making operations avoiding outsourcing costly CNC machines.

How to Use Them Properly and Safely

These steps are needed to ensure that a metal hole punching machine operates safely and efficiently.

Choose the relevant punching tool according to the task.

Take your time to set the machine like manual says and use all of safety guards that goes on it.

Fasten the metal sheet securely on to working table of machine

Set the punch depth to where is best.

Single hit the tooling and apply gradual pressure by starting from bottom to feedShearing(2)INDEX MILLInitiate machine then, single cycleApply light pressure until it has passed through(Node failure with over penetration of material likely happened here.)

Take off the punched matter, and repeat if necessary.

After use, be sure to clean the machine thoroughly and store it safely. 3

Safety glasses, gloves and ear protection are a must in using metal hole punch tools.

The domain of the metal hole punching machines is undergoing constant progression to fulfill with the progressing needs brass tacks and bauble hunters. These machines now have features such as automated feeding systems, touchscreen interfaces and wireless controls that accelerate production speed while allowing better control for more accurate metal processing. Purchasing the newest kind of metal hole punching machine can transform how work on your metalworking projects bringing both time and cost savings in addition to accuracy as well as an outstanding finish.

Our dedication to quality, reliability and continual improvement of products and service is an ongoing procedure. Our Lihao team is highly skilled and offers cutting-edge solutions. We are the true number one solution in stamping automation. We place great importance in ensuring consumer satisfaction by consistently supplying the quality highest products plus services.

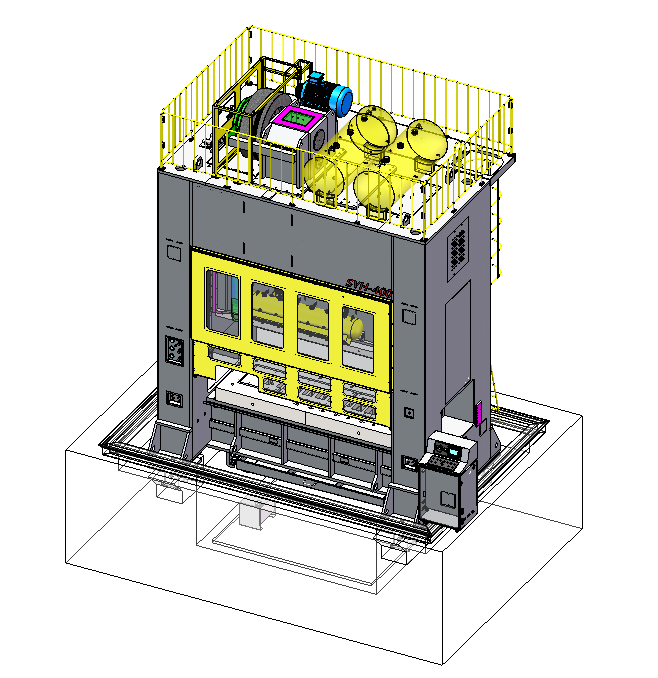

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.

We have been specialists in the design and engineering of durable tooling that minimizes setup adjustments and production that is scrap is reduces. Our metal hole punching machine are able to deliver training that is global commissioning that ensures seamless integration and optimized performance globally. With in-house manufacturing plus quality parts that are spare we guarantee minimal interruptions plus the productivity this is certainly highest. As a ISO9001:2000 that is certified plus EU CE we abide by the high quality standards being highest.

Lihao Machine is a huge business is leading the industry because 1996. It is only a trusted supplier both the national and international markets. Our products are trusted in lots of industries throughout the world. All over the globe with over twenty offices in China and an overseas branch in Asia We provide our customers. We offer tailored solutions throughout various industries with this robust technological capabilities.