Progressive die and stamping are significant methods for manufacturing metal parts. Let’s find out how they work and why they’re so useful!

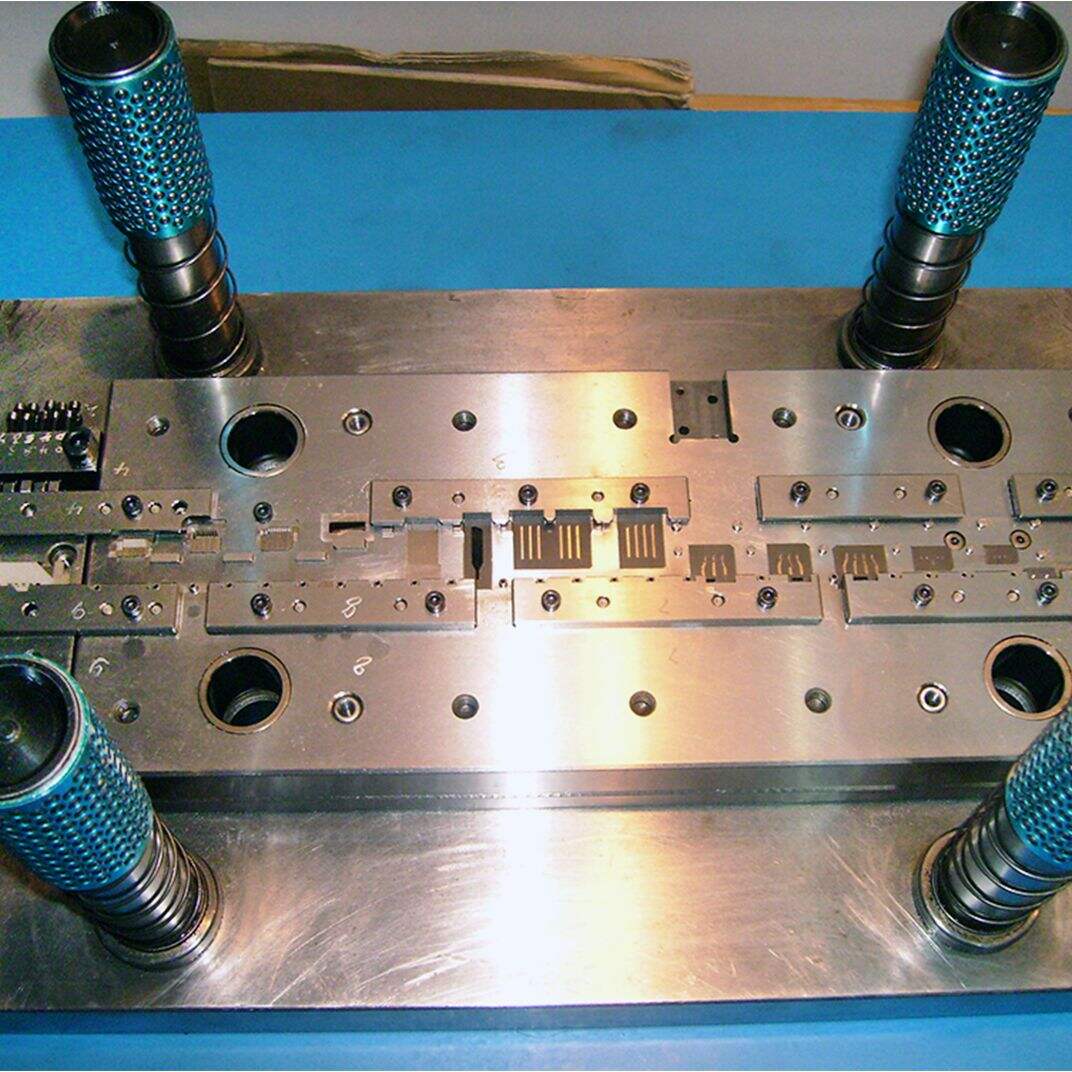

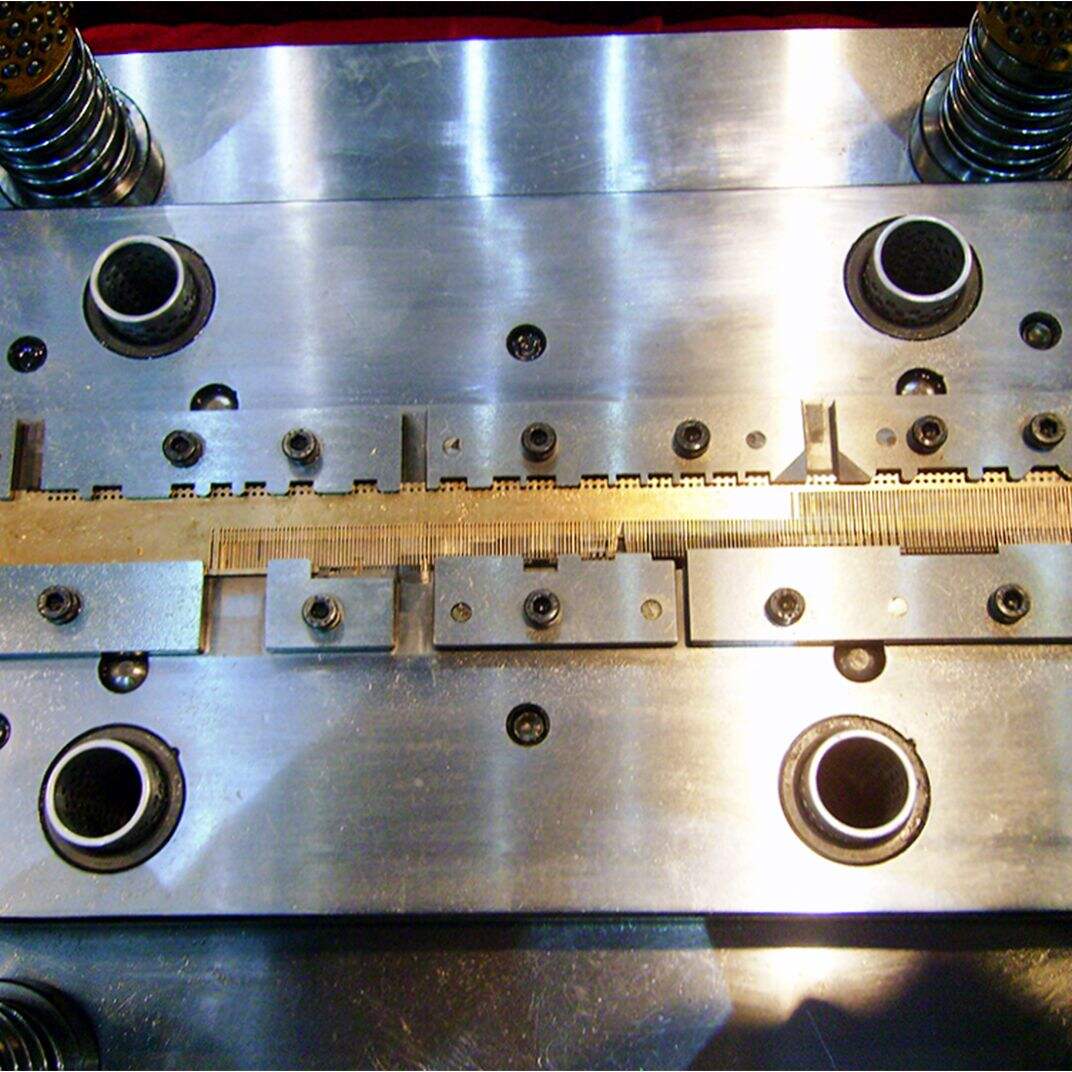

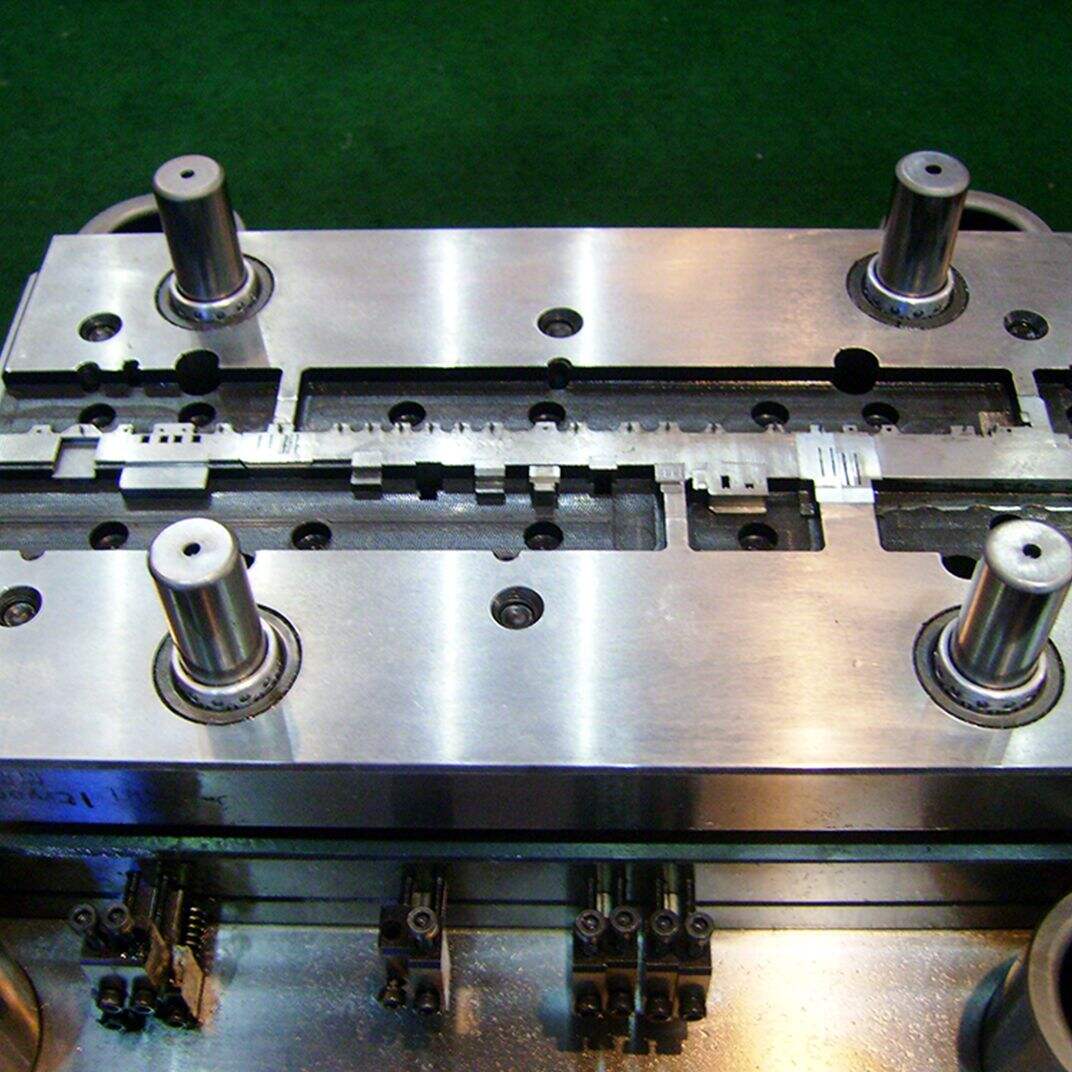

Both progressive die and stamping are processes that involve the manipulation of metal sheets in order to create various forms. A progressive die is a tool with multiple stations that cut and form the metal. As the metal sheet travels through the die, each station does something different until the final part is formed. Stamping involves pressing a machine down onto the metal sheet to form it into the shape we want.

One major innovation provided by the progressive die and stamping is that they enabled the manufacturing process to be sped up. Progressive die makes it possible that many tasks can be accomplished at once, which saves time and workers. Stamping also serves to form metal sheets rapidly and precisely, which makes production faster and less expensive.

Progressive Die and Stamping has its benefits. For one thing, they help create high-quality parts with fine details. They are efficient, saving money by reducing waste and required labor. These techniques contribute to ensuring parts are uniform and fit each other well.

In recent years, developments in technology have advanced progressive die and stamping techniques. For instance, some companies use computer programs to design parts. They also rely on sensors to monitor and adjust the stamping process as it’s occurring. These new technologies facilitate a superior manufacturing process.

Consistency.Finally, when you use progressive die and stamping, you get very accurate parts. Progressive die allows manufacturers to produce parts and components with precise shapes and dimensions. Shaping metal sheets through stamping prevents any distortion to the shape, so the parts will fit together perfectly in the end product.