Progressive die and stamping are useful methods for creating things with metal. With the help of these methods, it can make the process quicker and less wasteful. What exactly are levers and how are they employed in factories?

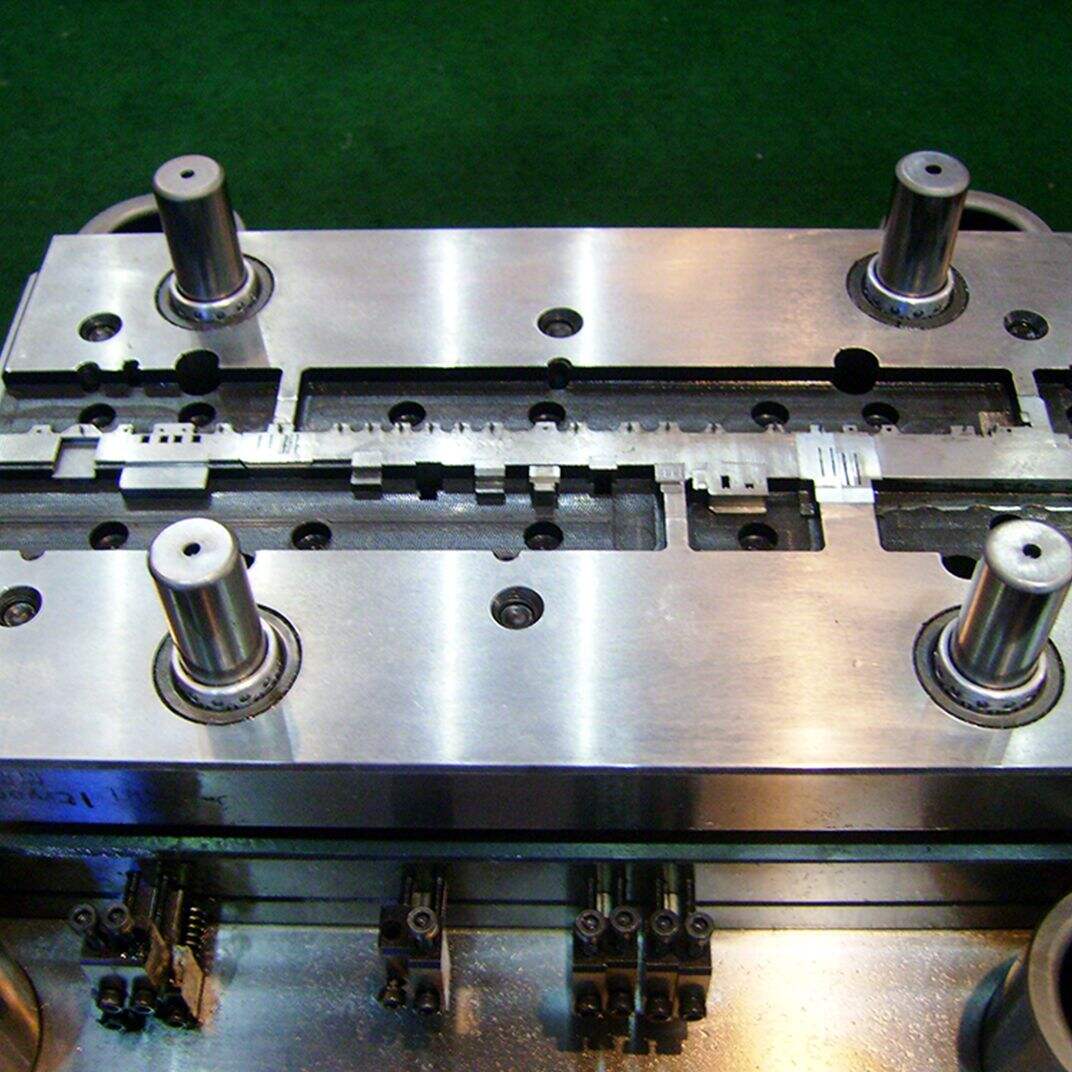

Progressive die and stamping can save time and money when creating metal items. These processes help guard against each piece being made correctly and swiftly. Another major advantage is that they keep waste down. In other words, less metal is wasted every time a piece is made, which can add up to big cost savings in material waste.

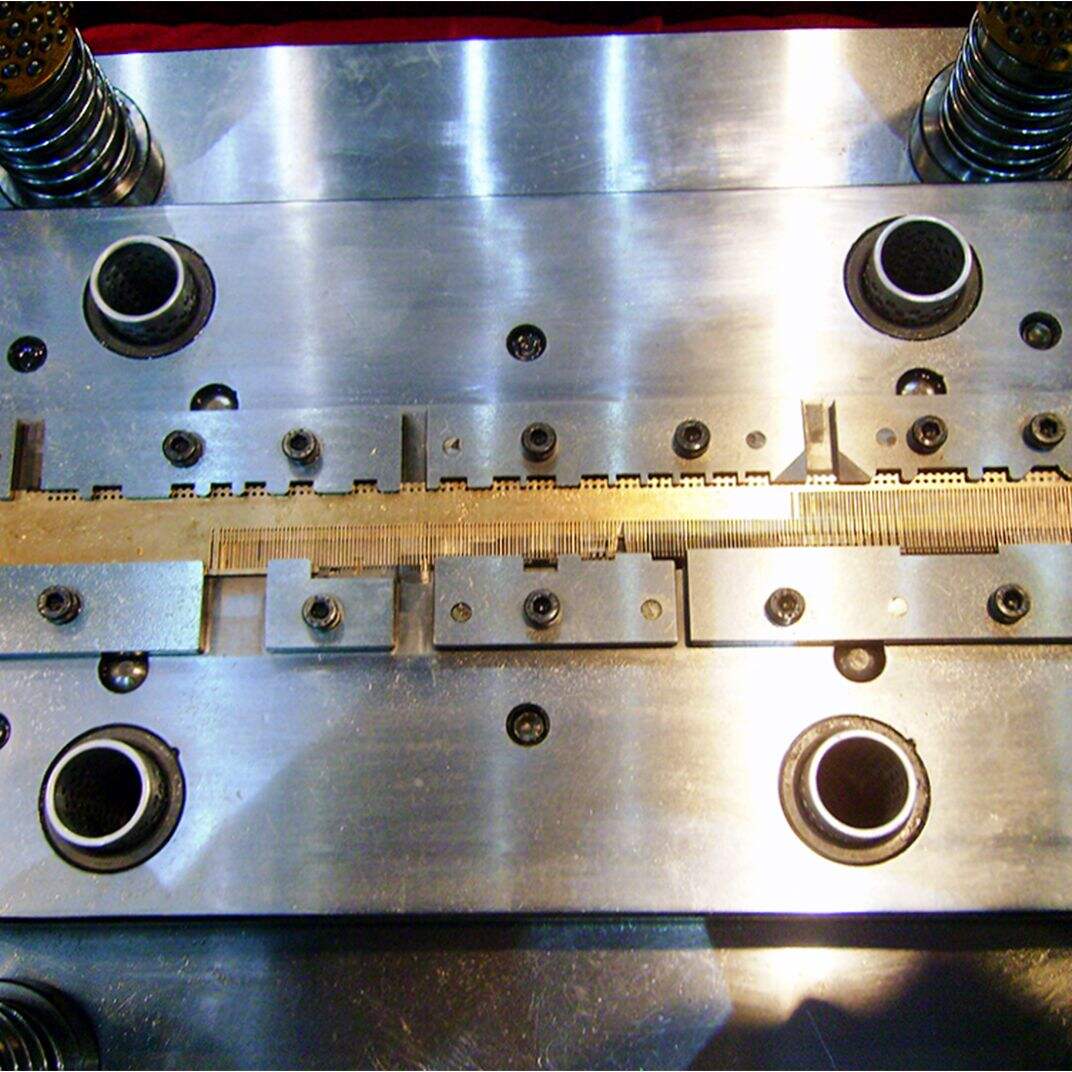

Progressive dies and stamping can make things faster. They let many of the steps occur at the same time. That is, each piece can be produced faster and with less error. This streamlines the process of planning and saving, and collectively, it ensures that everything you have is of the highest quality.

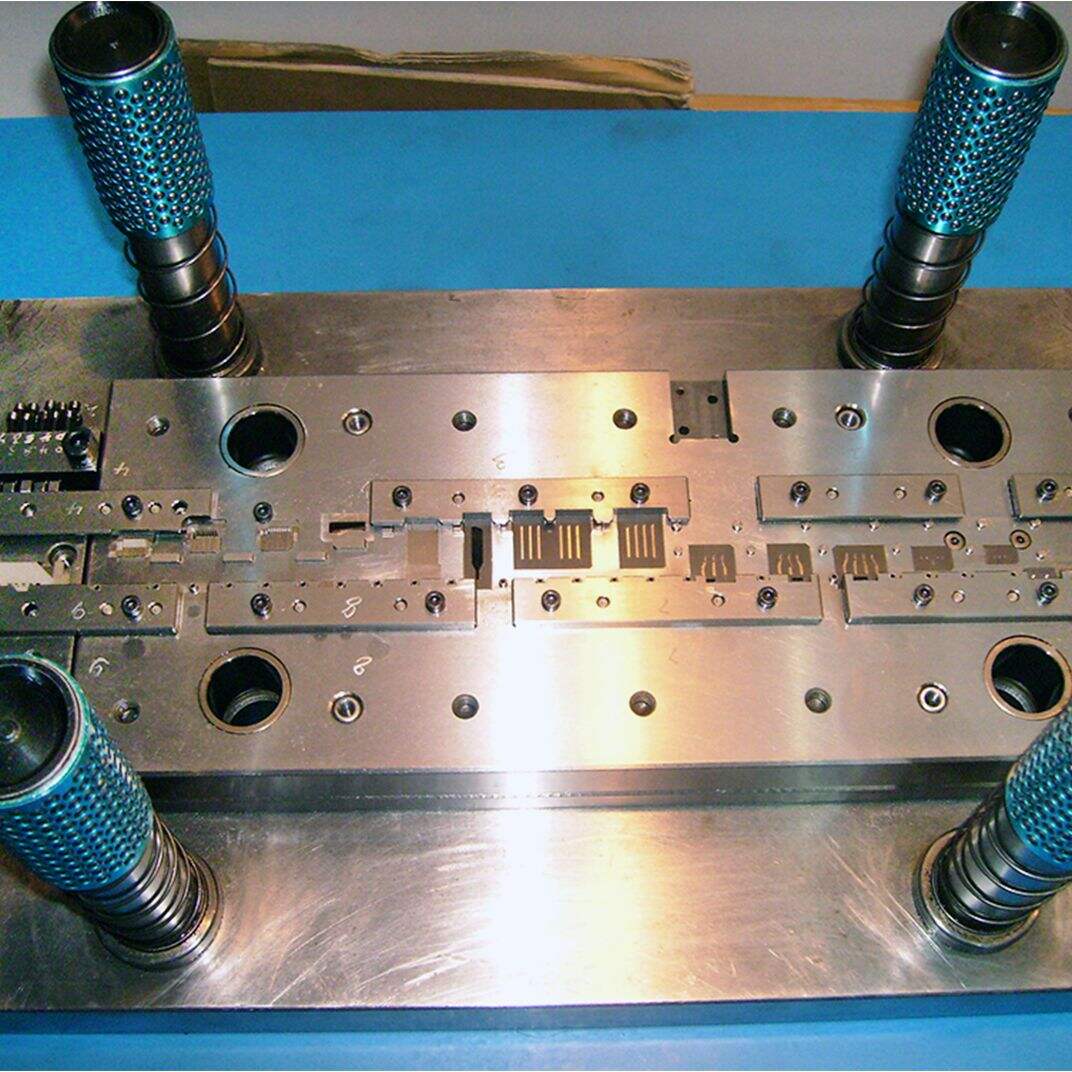

Progressive die and stamping is also commonly employed for producing complex metal parts that are difficult to make by hand. These are methods that make it easy to form detailed shapes and designs in factories. This creates new horizons for what you can make of metal and guarantees each piece exactly as it should be.

There have been a lot of new ideas on progressing and stamping recently. These enhancements all contribute to making the procedures faster and accurate. For instance, computer programing can now be used to generate detailed plans for individual parts, making sure that manufacturing is not only accurate, but also consistent.

The progressive die and stamping press have wide application to a variety of parts and products. And from the looks of things, these techniques can get you from the most basic shapes to the most complicated designs. This adaptability among other things, make them the perfect choice for shops needing to make a range of metal parts.