Have you heard of components that split into progressive die? These are critical components that meat in machines to produce consumer goods like car parts and home appliances. Whenever you pass by a vehicle or a gadget within the urgent surroundings, there’s a extensive attack which is progressive perish components were used to manufacture it. These components improve the efficiency of machines and make production processes much smoother. Here, we will discover the use of progressive die elements to produce more products in a smart and convenient way. And we will check out some sweet engineering that is clever, tough stuff that lasts, stuff we can calibrate to suit our needs and components built for efficiency. Lihao is the perfect company for all these essential items to make our customers succeed!

As our UniMass engineer colleague once said, it is even more crucial to be thrifty with the way we use these resources when parts are produced by machines. This is where progressive die factor in. These features improve production by enabling faster, more efficient part creation with minimal waste. A very critical point to understand as it saves a lot of time and money for us. If we can make more parts faster, that means we can produce more things for people who need it most. This benefits all of us, as it maintains a steady flow of goods in the supply chain so that we have products when we want to buy them.

A considerable difference in functioning can be made through the design of the stamping die. Our lifestyle is what makes us smart with the materials that are needed to get it right. We want to ensure that we maximize the use of every piece of metal we process in order to produce more parts. Considerate and attentive designs can lead to ineffective experiences causing wastage of finances and time. To put it another way, we are not only interested in making parts, but also in doing so responsibly with respect to our ecology and clientele.

Lihao makes its progressive die components with only top materials and best practices. This must be done with extreme care as we always need to take into consideration that every part produced is as accurate and precise it can possibly get. It means every piece we manufacture will fit well into its final place. For instance, we apply strong & durable special material such as high speed steel and carbide. We additionally utilize clever techniques around wire EDM and CNC machining also enabling us to produce the very best parts for our customers. This helps us to ensure a level of quality the customers can count on.

But the fact is, each machine has unique needs — and that’s where customizable progressive die components come into play. Our customers need different customised options, and thus we provide them with a lot. So we are able to produce parts that precisely fit our customers' needs for their specific machines. The reason we are able to do this is by customizing our components, which allows more people the ability to access the required parts that keep their machines up and running smoothly and efficiently. That versatility is essential for us to cater to a range of industries and offer various needs.

Last but not least, Lihao focuses on high-performance progressive die elements ideal for mass-production. We realise that many of our customers need to make parts quickly and cost effectively. Which is why we design components that have the ability to withhold high volume production without sacrificing quality. That also ensured that parts are done and available for our customers right when they need them but not at the cost of quality or performance. We also want to make sure that every customer can count on us for his/her manufacturing service satisfaction.

Our dedication to reliability, innovation and continual improvement of your products and service is an ongoing procedure. Our Lihao team is extremely experienced while offering cutting-edge systems. We have been the top solution stamping automation. We place a whole large amount of focus on client satisfaction by consistently delivering the better products and services.

And over 26 years experience in industry leadership, Lihao Machine is a supplier which was top the domestic and international markets. Our products is widely found in a wide range of. All over the world with nearly 20 offices across China because well as an overseas subsidiary India we provide our clients. We provide customized solutions in several industries, with your robust technological abilities.

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our progressive die components offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.

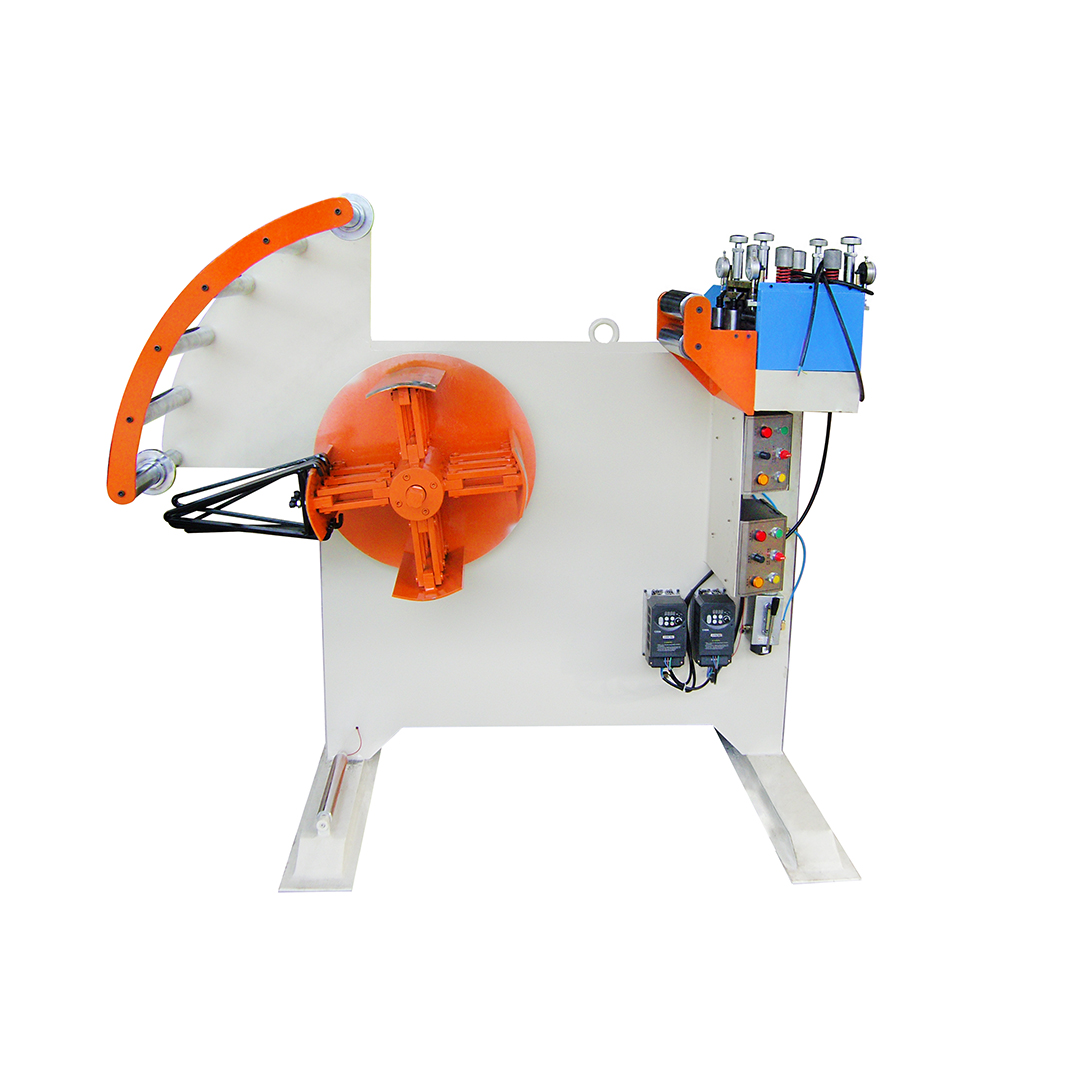

Lihao Machine offers tailored solutions along with a wide range of services to fulfill various customer. With a broad variety of merchandise, including 3 within one feeders, Decoiler Cum Straightener machines, NC servo feeders, and punch machines, you can expect integrated service covering manufacturing design, sales, service, and trading. Our R&D team is dedicated to ensuring customization and technical discussions, ensuring that each product was designed to hook up together with your unique specifications.