Very important for manufacturing car parts or other stuff of metal is progressive die. It allows us to speed up the process, to make it cheaper but also possibly more accurate. We will explain how the use of a progressive die design can be beneficial to our brand, Lihao, when producing better products.

Efficiency is about doing things faster and better, said Ladd, and that saves money and improves quality. That means thinking how the metal pieces in the die can be laid out to be cut out quickly and with minimal waste. We also design our dies to be more efficient, saving time and money with each part we produce.

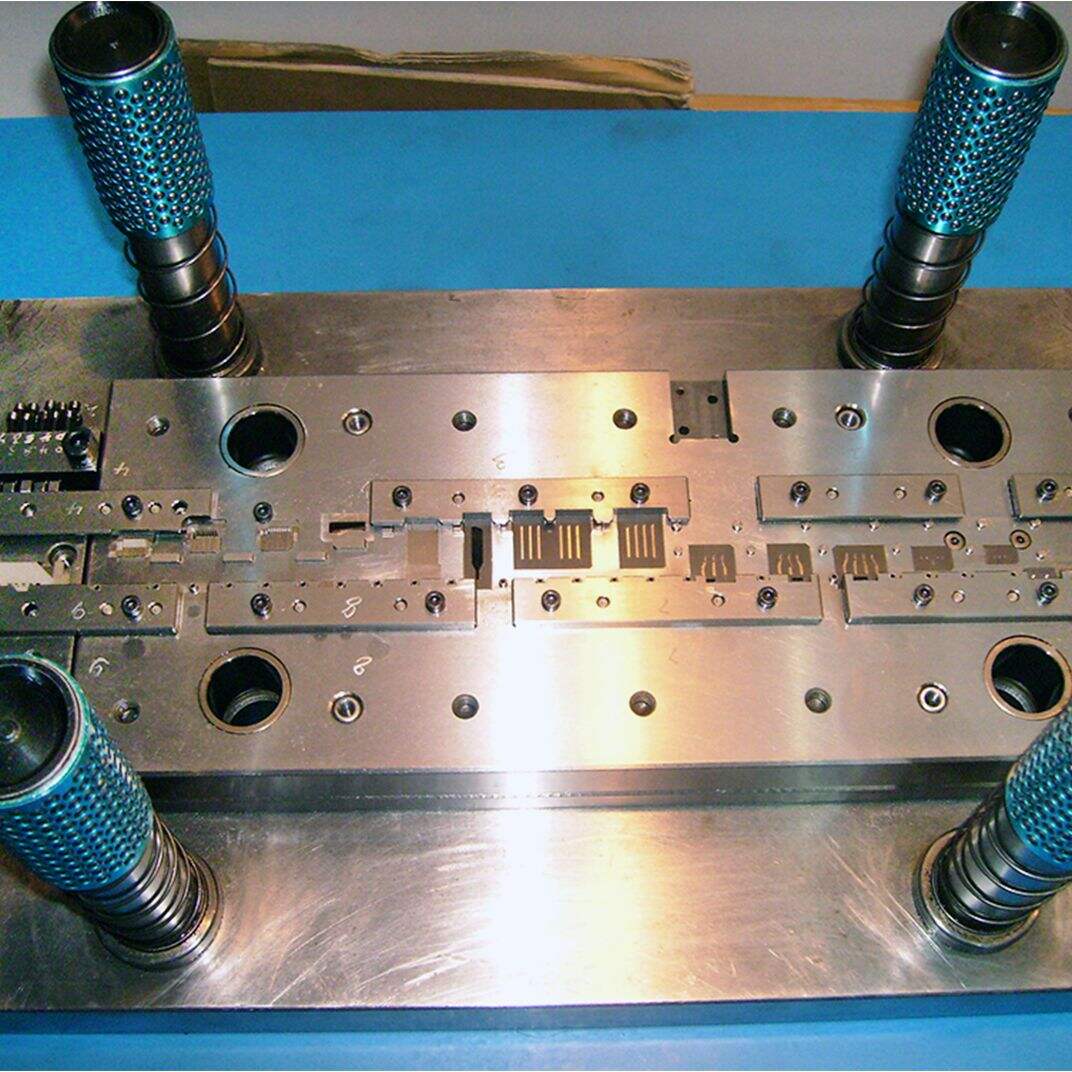

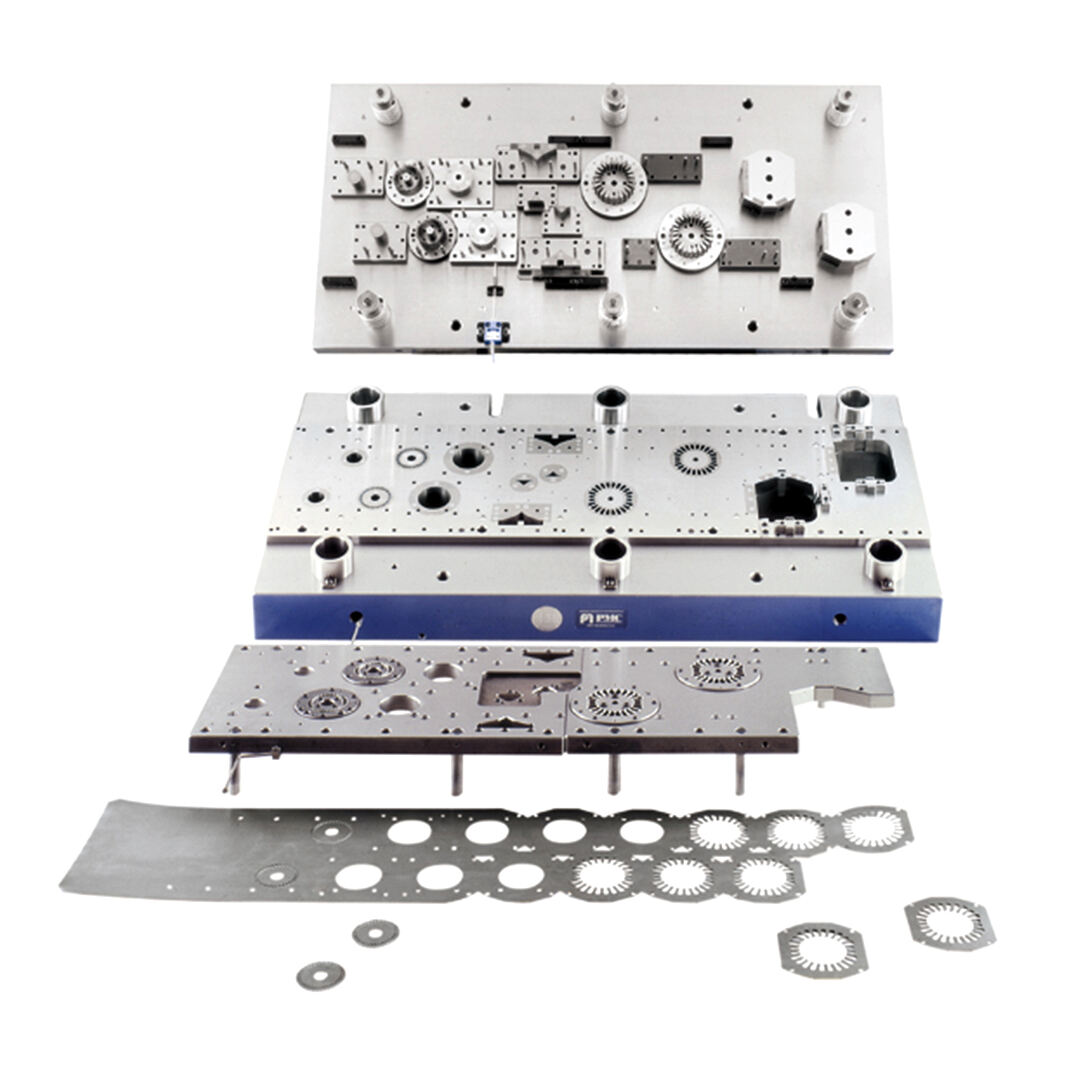

We also need to pay attention to the manufacturing process of machining by multiple molds. That process includes ensuring that all of the steps of making a part are linked in the most efficient way. By engineering our dies to mesh and flow together, we can produce more parts in less time. For our customers this is good as it means they can have their products quicker.

Obtaining Precision for Parts with Progressive Die Design is Another Important Aspect. Precision is “making sure each part is made the same way every time. So that we can avoid making mistakes and make sure our parts fit together. With stamping die, we are able to monitor the process more easily and produce better parts.

It is also essential to be innovative and creative when designing progressive dies. That is, finding new and better ways to make our dies work. We need to design creatively, so that we can arrive at fresh answers to familiar problems. This is how we continue to outperform our competition and improve our product for our customers.

Boosting efficiency with state-of-the-art progressive die design techniques rounds out the equation. This includes taking advantage of the most modern tools and technology available to increase our dies performance. When we make more parts in less time using advanced techniques, that’s good for our bottom line and for our customers.