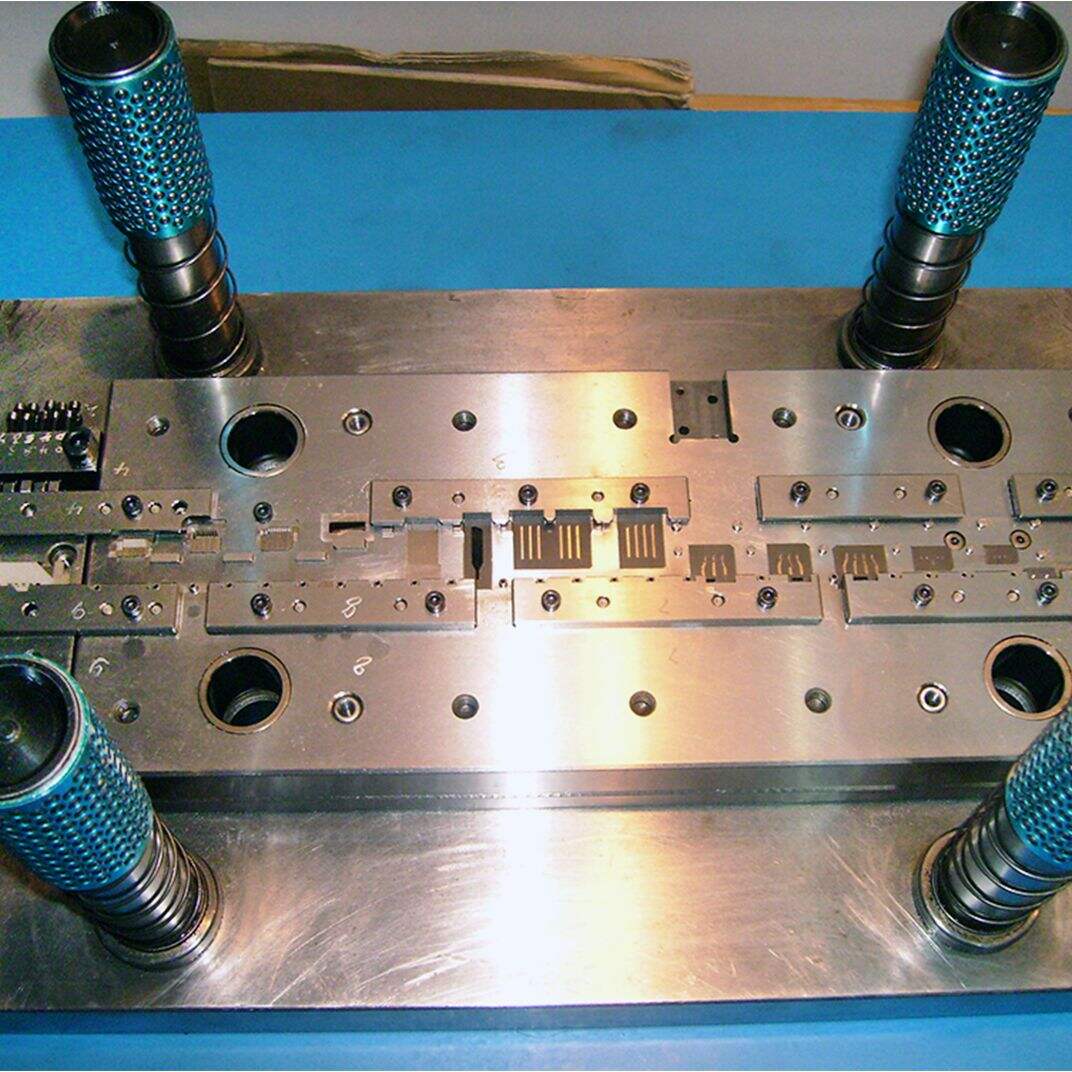

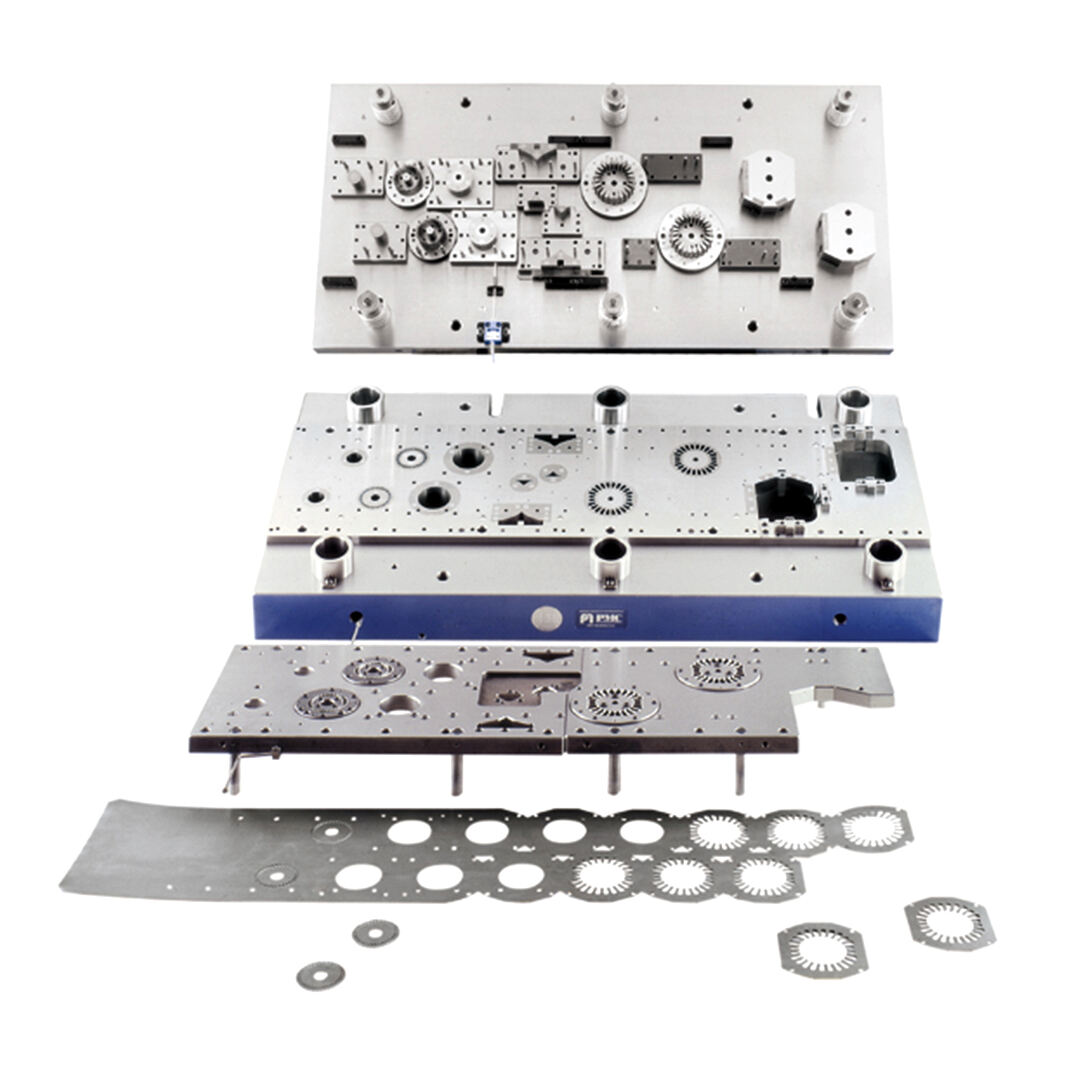

Metal stamping, specifically progressive die metal stamping, is a method used to create metal parts at high speeds and precision. The machines in this process can produce many pieces at a time, so it is a quick way to make things. Lihao is a progressive die metal stamping company with years of experience making high-quality metal parts.

A nice thing about the progressive die metal stamping process is that several pieces can be made at the same time. It saves a tremendous amount of time versus doing each item one at a time. Yet another advantage of the process is that the parts are quite accurate and look alike.” This means that they fit together exactly. Lihao relies on this process to produce metallic parts for many products, including cars and household appliances.

Progressive die metal stamping is a quick way to produce metal parts because it’s able to make multiple parts at the same time. This is what allows Lihao to produce a large number of parts quickly — critical when many are required. The machines used in this process, too, are very fast and very accurate, so there’s less error. This not only saves time, but also money.

One major upside of this process is how precise parts can be made. And the machines are very accurate, so that the parts that are created are very accurate. This is crucial when it comes to components of cars, for example, where even the smallest bit of difference could lead to trouble. Lihao applies this technique to get parts that are the right size and shape all the time.

Tutorial on progressive die metal stamping This technique is great for making all kinds of metal parts. Lihao uses it to produce everything from small bolts to large car panels. The machines can be reconfigured to produce different shapes and sizes, which makes it big for lots of projects. That flexibility is why Lihao and companies like it still use progressive die metal stamping.