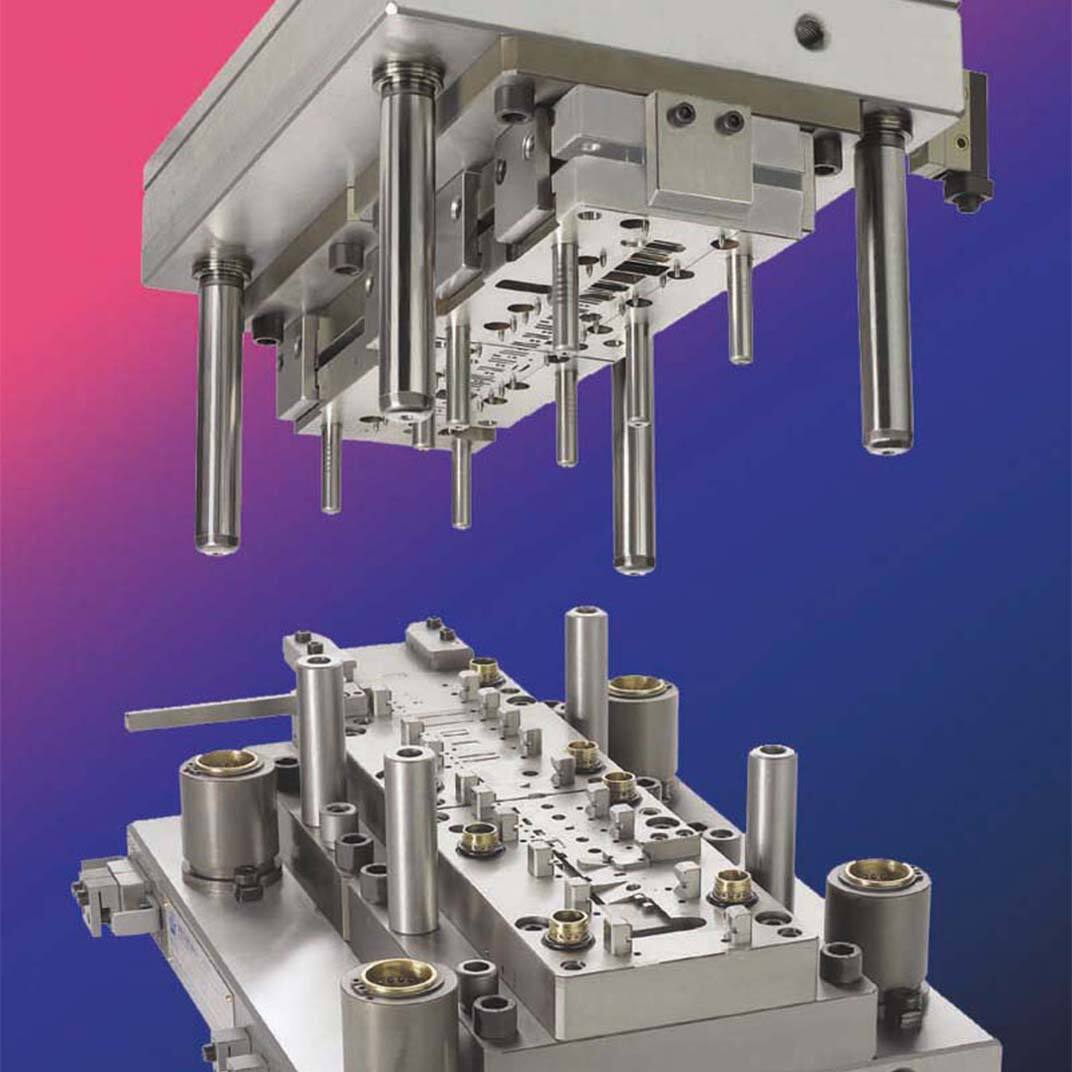

Metal Working Is Easier Than Ever Making things out of metal has never been easier. Progressive die press One method for making metal parts faster and more consistently is using a machine called a progressive die. This special machine is the way factories work smarter, not harder.

To simplify: Think of a progressive die press as one huge cookie cutter that cuts many shapes all at once. Instead of cutting a single shape like a normal cookie cutter, it can cut out an entire tray of shapes all at once. This allows workers to make metal parts much more quickly.

It used to take forever to make metal parts, before progressive die presses. Each piece had to be cut by hand or a machine that produced one piece at a time. Using a stamping die, factories can make hundreds — even thousands — of identical metal pieces in a day. This makes the job so much easier and faster.

It’s a progressive die press that not only allows factories to make metal parts faster but also ensures that they are all identical. Since the machine cuts out many pieces at a time, they all nest just right. This makes everything run well and cuts down on waste, which saves time and money.

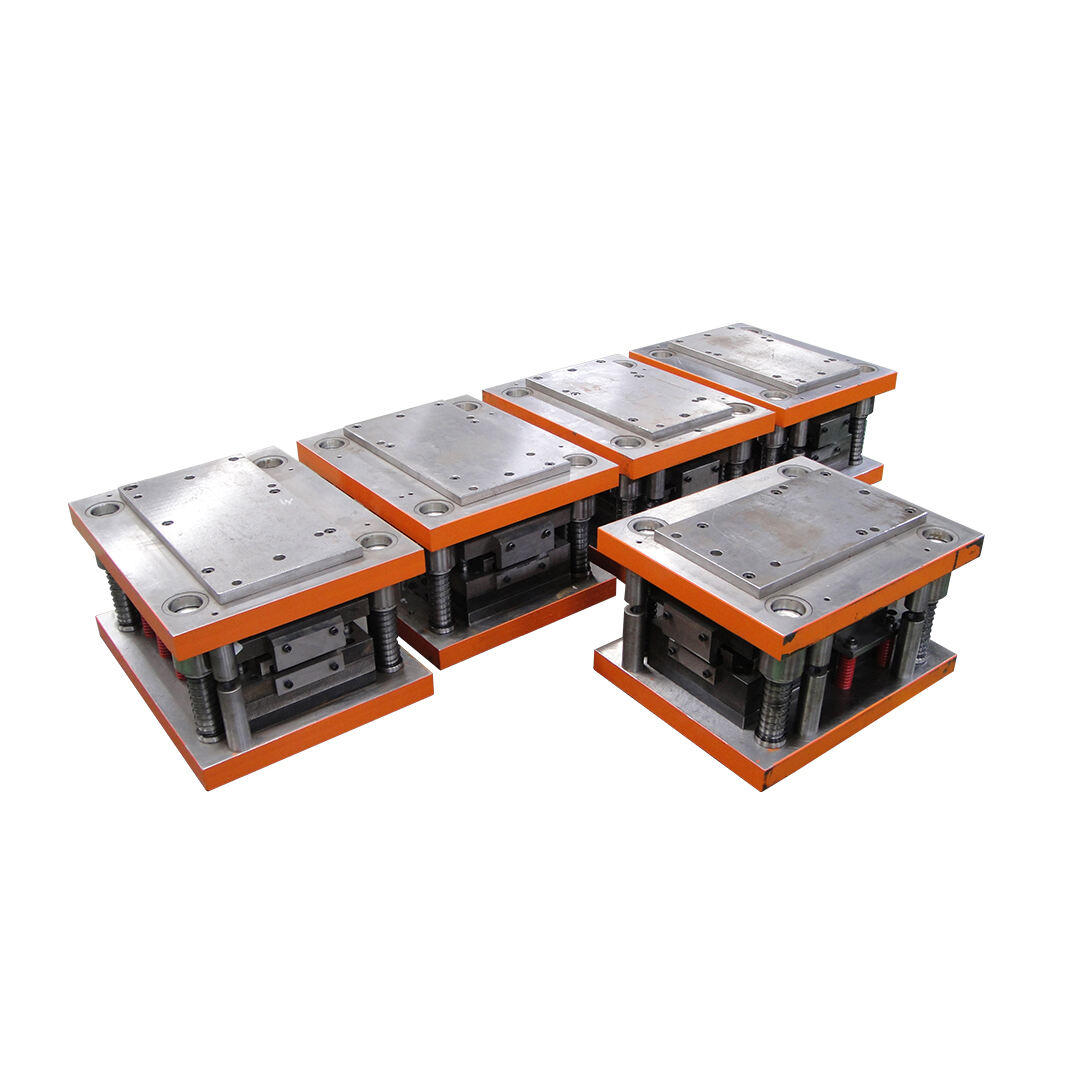

Progressive Die Advantages There are a number of reasons why a progressive die press is commonly used. One big advantage is that it allows factories to make more pieces faster. And because the machine can produce many parts simultaneously, workers can complete their tasks more quickly. Plus, the machine is precise, ensuring each metal piece is produced just so, cutting down on errors and increasing quality.

Foreign trade -In addition to metal parts, progressive die presses have many uses. Building cars, TVs, fridges and other goods, these machines help companies around the world produce products more quickly and efficiently. This renders them invaluable for any business dealing in metal too.

We have been specialists in the design and engineering of durable tooling that minimizes setup adjustments and production that is scrap is reduces. Our progressive die press are able to deliver training that is global commissioning that ensures seamless integration and optimized performance globally. With in-house manufacturing plus quality parts that are spare we guarantee minimal interruptions plus the productivity this is certainly highest. As a ISO9001:2000 that is certified plus EU CE we abide by the high quality standards being highest.

Our dedication to quality, improvement and continuous reliability of products and service is a constant. Our Lihao team is extremely skilled and offers cutting-edge systems. Our company is the stamping possibility first automation. We have been focused on client satisfaction, providing top-quality products outstanding service.

Lihao Machine provides tailored solutions also as a complete service meet up with the various needs of customers. You can expect integrated solutions which cover design, production and sales. Our R&committed D team provide you with customized choices and technical discussions making sure each option would be suited to your unique criteria.

With 26 several years of industry leading position Lihao Machine is a preferred supplier the domestic and worldwide markets. Our items are utilized in a wide variety of around the planet. Our customers are global through a lot more than 20 offices throughout China in addition to branch in Asia. Our technological expertise allows to provide specific solutions for assorted industries.