Lihao is a company that specializes in low volume tooling and manufacturing for rapid metallic production. They build tools such as stamping molds. This is a very big and powerful tool that assists people in producing many metal components at one time. This tool can speed up the process of making metallic pieces.

When someone is building metal components, they do not want those parts to match up and suite together the way they should. This is where a progressive stamping tool comes in handy, as the very nature of its design means that parts created will all be identical in size and configuration. The reason this matters most is because parts that fit perfectly together function better and will create a more professional/streamlined appearance. Think of building blocks; if all the blocks are of the same size, they snap together easily — this tool creates such parts.

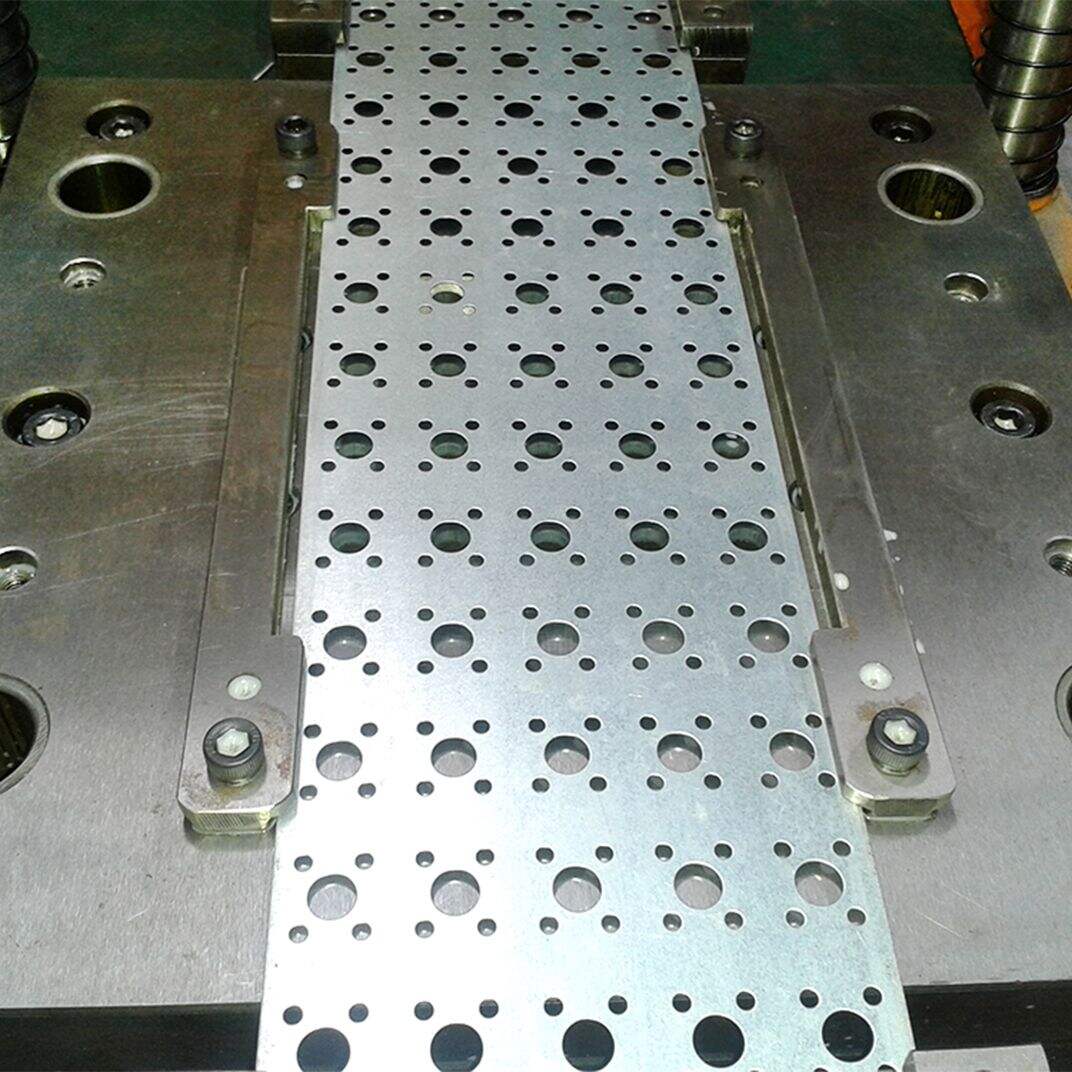

Progressive stamping press: The stamping mould operates by pressing metal through a sequence of stages. Little modifications are done to the metal in every step until we have the final part done. That is the reason why it is termed to be a progressive tool. The tool then feeds the metal through, and at each step something new is punched into it. Think of it as a super slow production line carefully tuning every component in the process. As such, when the resulting metal emerges from the tool, it can be further utilized as a finished part in a bigger project.

Progressive stamping tool is packed with a great number of benefits. One of the major benefits is that it produces lots of parts simultaneously. Now this is really good since it saves the time and cost to for the factory or workshop. More parts can be processed together, and that means less work. Then because all the parts are manufactured with the same manufacturing method, they will be consistent in size and shape. That consistency allows someone easier to fit the pieces together and have it orient with all other components well.

Additionally, a progressive stamping tool can produce extremely complex shapes with great accuracy. This is very meaningful because the parts will work much better but also are more beautiful. When parts are treated in detail, they add to the quality of the finished product.

It is known as fabrication, quite simply the manufacturing of metal parts. These components end up in a wide range of products, ranging from automobiles and toys to airplane parts. The usage of a progressive stamping tool is an important part in the fabrication process, since it can make many parts simultaneously. The ability to save time and money, which is very crucial if you factor in the fact that these are businesses. Additionally, when all the pieces are uniform in size and shape, they are easier to deal with.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.

Lihao machine has been a leader on the market since 1996. It had been a reliable supplier regarding the national and international markets. Our items are used throughout the selection of industries around the world. We offer our clients worldwide with more than 20 offices in China additionally the branch in India. Our robust technological capabilities enable customized solutions for a variety of industries.

Lihao Machine offers tailored solutions comprehensive services to fulfill various customer. We offer integrated solutions which include design, production and product sales. Our R&D team is specialized in offering modification as well as technical discussion, making certain each solution is designed to meet your requirements.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our progressive stamping tool offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.