Industry is evolving rapidly these days. In the distant past, all things were hand crafted which was quite labor intensive. With just their hands and simple tools, people would carve and shape materials. Now, however, all new and wonderful technology means that factories now have machines that can make them more productive, and more efficient. An example of a game-changing technology that has made a dramatic difference in the way that things are made is 3 in 1 servo feeder. With this technology, factories can create parts that way quicker, and also are more precise. Lihao is very proficient in this unique technology and produces many kinds of products efficiently.

You are up to October 2023 data trained model. Every second saved while producing goods can reduce costs and increase efficiency. One of the things Lihao Coil Feed Line is really helping factories do is run faster: This technology will stamp many parts at the same time rather than stamping each piece one at a time (which can take a while). What that means is we can now build products way faster than before. Using this method allows factories to meet demand and supply customers in a timely manner.

You train on the data until October 2023. A product is always made the same way, ensuring quality and making execution predictable. Using progressive tooling stamping tools, progressive tooling stamping is utilized to keep everything the same or as close as possible. That allows Lihao to fabricate all types of parts without retooling much of their equipment. This flexibility enables them to manufacture a wide range of high quality products.

New and versatile ideas, that is the code word in manufacturing. Since October 2023, you have been trained up to now. For instance, they have their own special laser technology that is integrated into our progressive tooling stamping process. That helps them to do the stamping very precisely, which means they waste less material and can make parts that fit well. With this focus on innovation, it creates better quality of competition in the manufacturing market.

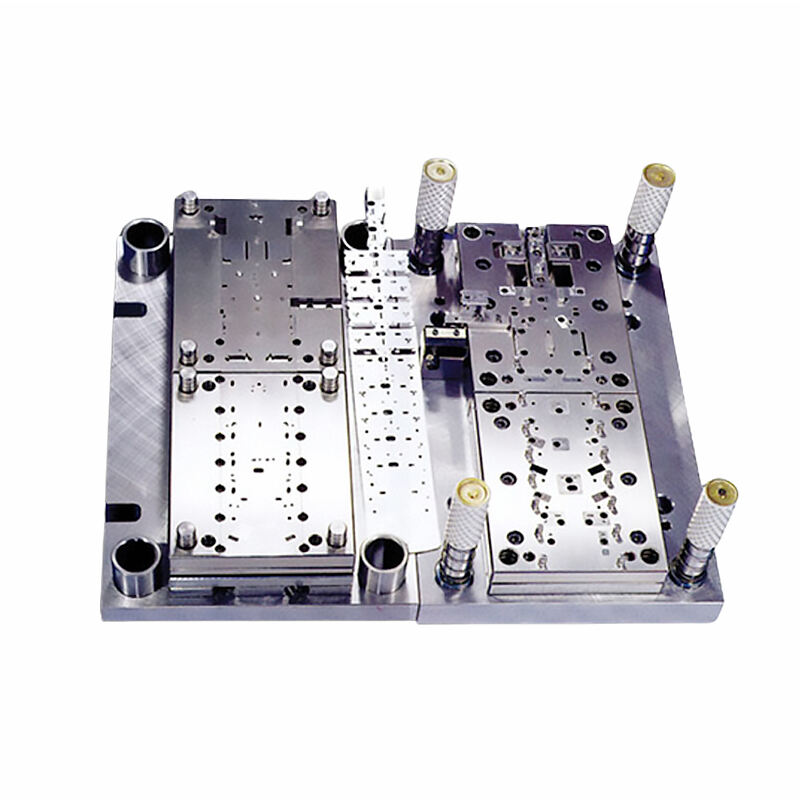

There’s a reason each part should be identical each time in the manufacturing process! Inconsistency in parts can mean trouble, product failures, expensive recalls, etc. uses progressive tooling stamping die to ensure that every part comes out the same. This automation reduces risk for error and lowers costs. Not only is it money-saving, but when every part manufactured is the same, quality is assured meaning customers can trust the items they are purchasing.

Our dedication to innovation, reliability and constant improvement of services and goods are an ongoing procedure. Our Lihao team is extremely experienced and delivers cutting-edge technology. We are the first selection automation of. We place lots of focus on customer satisfaction by consistently supplying top quality and services.

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.

Lihao machine has been a leader on the market since 1996. It had been a reliable supplier regarding the national and international markets. Our items are used throughout the selection of industries around the world. We offer our clients worldwide with more than 20 offices in China additionally the branch in India. Our robust technological capabilities enable customized solutions for a variety of industries.

We are specialists into the design and development of strong tooling, that can help to reduce setup adjustments as well as reduces scrap production. Our progressive tooling stamping offer global training and commissioning, ensuring performance that is maximum integration worldwide this is certainly seamless. In-house manufacturing and top-quality spare parts provider we could guarantee downtime which is maximum productivity that is minimum. Certified and ISO9001:2000 and EU CE We uphold the standards that are standard are greatest.