When people hear these machines, they get some images in the minds like big and heavy pieces of metal that look messy and incomprehensible. But guess what? You can even teach kids about sheet metal stamping presses! This is why these machines are great, they assist in the production of metal items such as car parts to kitchen appliances. They help us in manufacturing, which is a fancy word for making goods in factories.

This article, we will take a close look at the components of sheet metal feeder. We will also see how it helps to speed things up more than ever! We will also pick up some useful advice on how to safely use the machine. Lastly, we will learn what makes this machine a good choice when producing in high volumes.

So, we will first discuss the different components of sheet metal stamping press machine There are plenty of critical elements to this machine, but we will examine its three most essential components: the hydraulic cylinders, the die, and the punch.

It is said long ago, things were made manually with lot of time needed and a real hard labor. And just imagine having to make each and every toy or car part piece by hand! It was only then that everything changed with sheet metal stamping press machines! Individual manufacturers can produce a large number of products fast with these machines, which is significantly faster and easier than doing it manually. It means that people can obtain the products that they want much quicker such as having a new cars or home appliance. That's why manufacturers make the same thing in less time and boutique items earn more money for manufacturers.

Sheet metal stamping press machines are the right machine to have when companies need to create hundreds of products in a short amount of time. Hiring tons of people to manufacture products by hand is a lot more expensive than these machines. What if, for every object a factory produced, the company had to employ an entire team of people? It would take forever and cost a lot of money!! The use of these machines is so much faster, allowing the manufacturers to manufacture more items relatively than without the machine. That is why, sheet metal stamping press machines become a very cost-effective device for large volume production.

These machine has the capability to produce fast and large number of products within a limited time. This also enables the manufacturers to deliver orders in a timely manner which makes customers happy. Finally, these machines are also highly accurate — they can repeat the exact same product time and time again without error. For manufacturers, maintaining this consistency is extremely vital since the way they make their products should be uniform across all of them.

Finally, sheet metal stamping press machines are environmentally sustainable! It means these are environment friendly as it do not generate a lot of waste. There are often no excess leftover bits when the metal is pressed to its needed shape. This ultimately provides detox from pollution and helps our planet to stay fit(!)

Our dedication to quality, reliability and continual improvement of products and service is an ongoing procedure. Our Lihao team is highly skilled and offers cutting-edge solutions. We are the true number one solution in stamping automation. We place great importance in ensuring consumer satisfaction by consistently supplying the quality highest products plus services.

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our sheet metal stamping press machine offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.

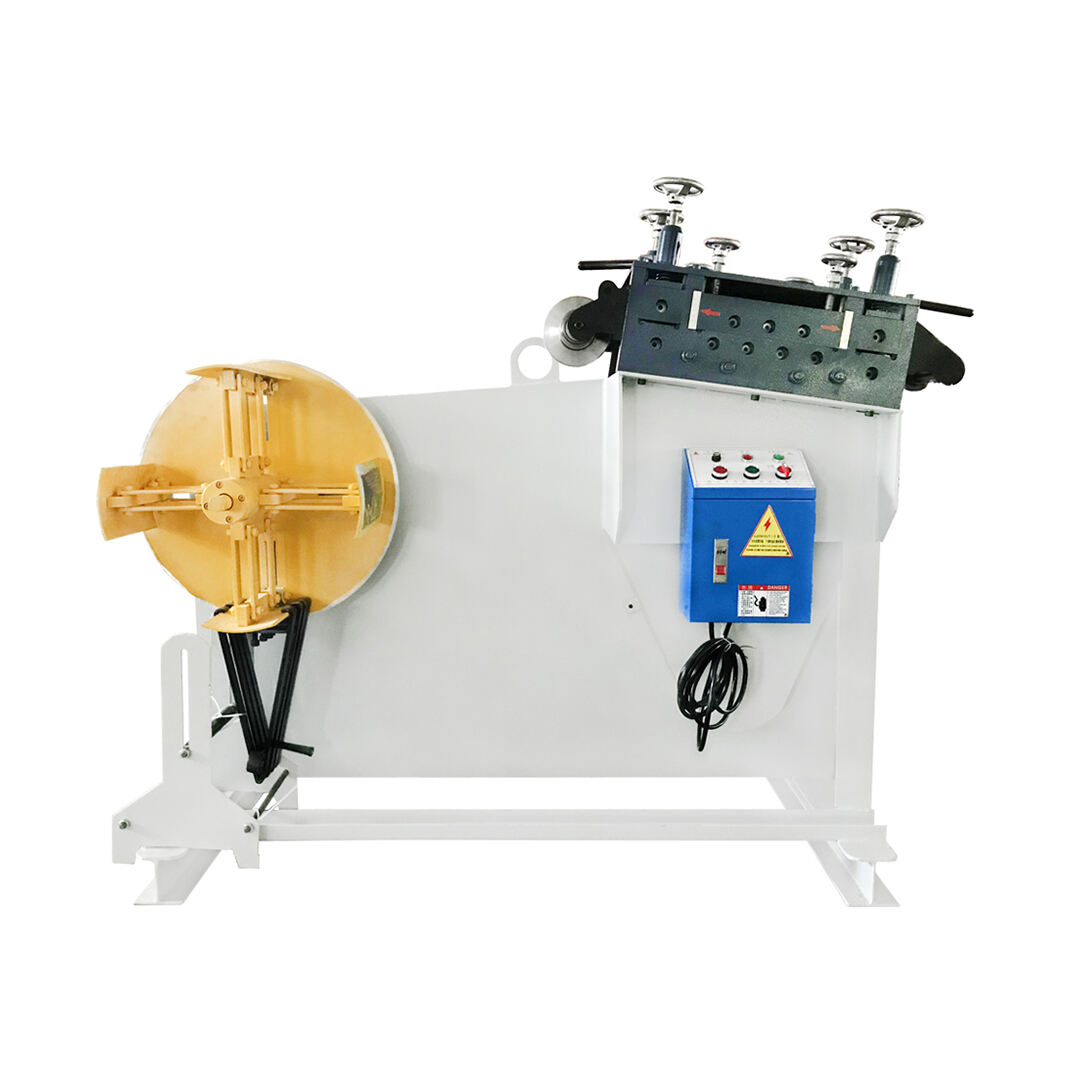

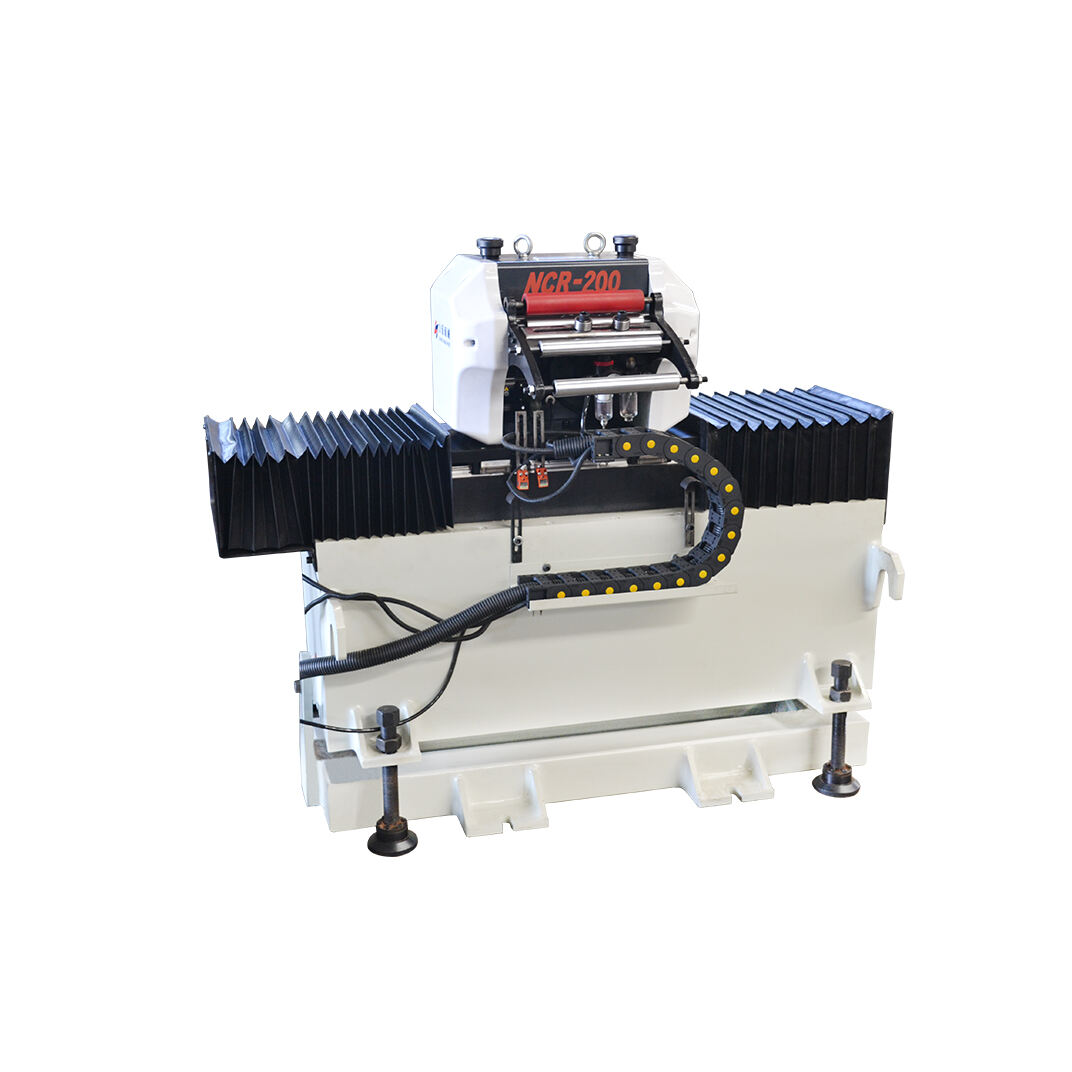

Lihao Machine provides tailored solutions in addition to a complete service meet up with the varied needs of your customers. Offering a number of products like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, plus punch machines, we offer complete service that cover manufacturing, design, sales, service, and trading. Our R&devoted D team customization options and technical discussions, ensuring that every product is customized to fulfill your individual needs.