If you were looking at some steel, and it was really thin but then cut pretty precisely — the assumption could be that there was a human involved in its making. Actually, most of the steel maker they have special machines called slitting machines that cut the steel in very small and precise sizes. There are several products that require slitting machine, which we use every day – such as cars, cans for food and drink, and kitchen appliances. However, what exactly is slitting machine steel and how do these machines make such accurate cuts?

Slitting machines are set up to process long sheets of steel and divide them correctly for smaller rolls or coils. With precision, these machines used incredibly sharp blades to cut metal down to the right size and shape needed. While this process seems simple, it requires quite a bit of diligence. The steel simply won't cut if the angles of the blades aren't perfectly aligned. This can create unnecessary loss of material which is not what companies are always looking for in their attempt to cut down on costs and resources. Slitting machine steel is manufactured with high-end raw materials that are robust enough to withstand the pressure and precision cuts required in this process.

Slitting machines play a critical role in steel manufacturing process. They aid in making accurate and quality cuts which can be used for a wide variety of applications. Slitting machines, for example which are widely used to manufacture the very thin sheets of steel needed to produce cans/containers. It required slitting machines for these sheets of steel to be carved to such precision and efficiency. In other words, this means that the use of slitting machines is a time saver for the manufacturer and at the same time helps ensure that their products are manufactured correctly.

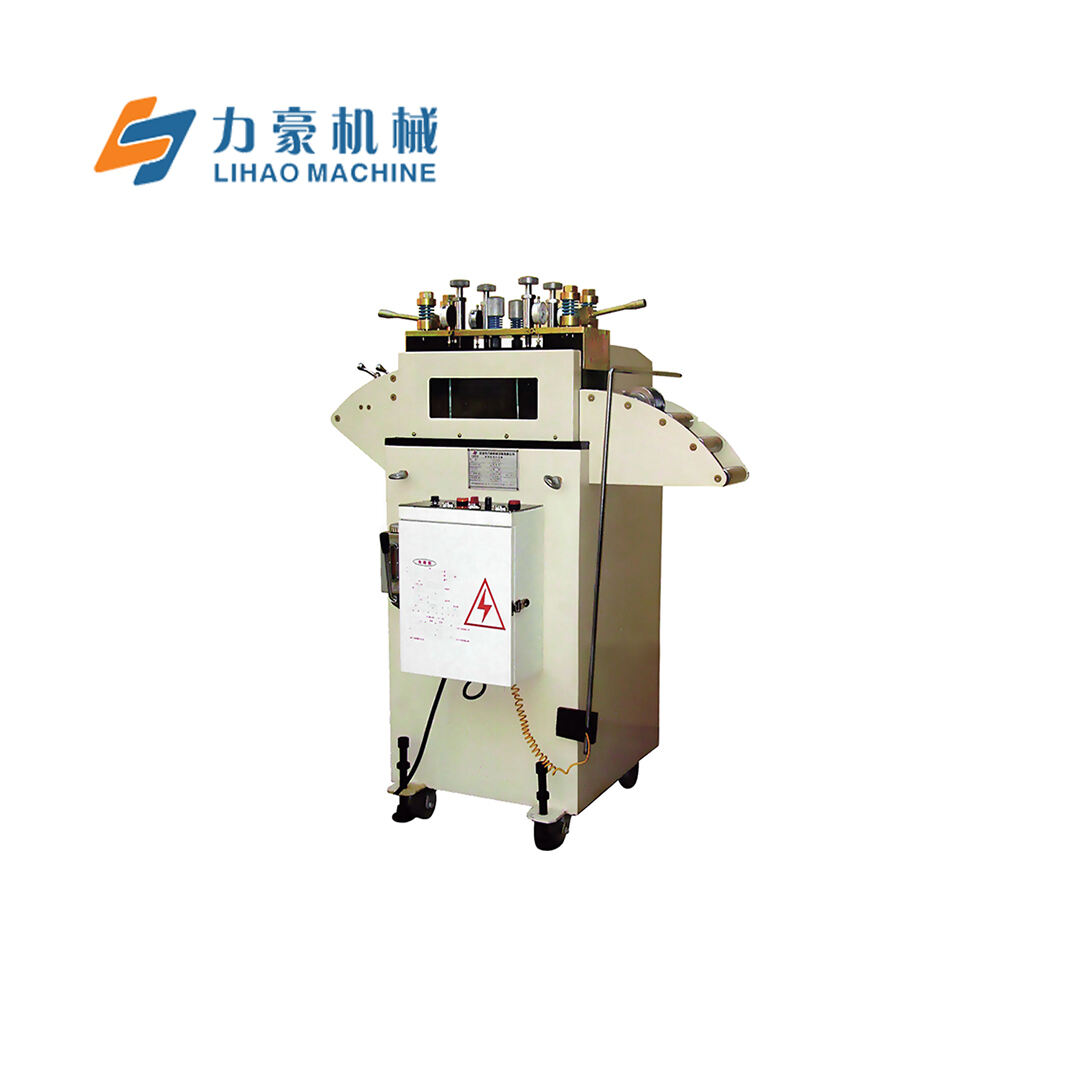

Many people who design and build steel slitting machine need to be quite skilled as well as familiar with the job they are in. There are many critical factors that an engineer must consider, including the dimensions of the blades and the composition of materials these blades consist of. Also, what thickness steel it is that will be cut. They must also ensure that the machines are user-friendly and easy to maintain. This will enable manufacturers to effectively use them without too many challenges. Lihao has an experienced team of professionals engineers for designing and manufacturing slitting machines that are built to deliver perfection in every run.

Manufacturers enjoy several benefits from employing slitting machine steel. It primarily enables them to produce high-quality and accurate steel cuts that are needed for production of different products. This level of precision guarantees that every piece of steel fits snugly into the products they are producing. Also, slitting machines are used to speed up the cutting process as well. Fractional DimensionsThese machines are then capable of slicing enormous flat metal sheets into small coils in a matter of seconds, thus saving time and space while helping manufacturers meet their production targets. Slitting Machines also reduce wastage at the end. Because these can cut more accurately, they consume a lower amount of overall material and raw resources which is suitable for the ecosystem as well as useful to the corporation.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our slitting machine steel offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.

Lihao Machine has been a company that has been leading the field going back 26 years. It is an established supplier the domestic and international markets. Our items are used in various industries worldwide. And over twenty offices in China and an India branch overseas serve customers globally. Our advanced technology capabilities let us offering tailored solutions diverse industries.

Lihao Machine offers tailored solutions along with a wide range of services to fulfill various customer. With a broad variety of merchandise, including 3 within one feeders, Decoiler Cum Straightener machines, NC servo feeders, and punch machines, you can expect integrated service covering manufacturing design, sales, service, and trading. Our R&D team is dedicated to ensuring customization and technical discussions, ensuring that each product was designed to hook up together with your unique specifications.

Our dedication to quality, improvement and continuous reliability of products and service is a constant. Our Lihao team is extremely skilled and offers cutting-edge systems. Our company is the stamping possibility first automation. We have been focused on client satisfaction, providing top-quality products outstanding service.