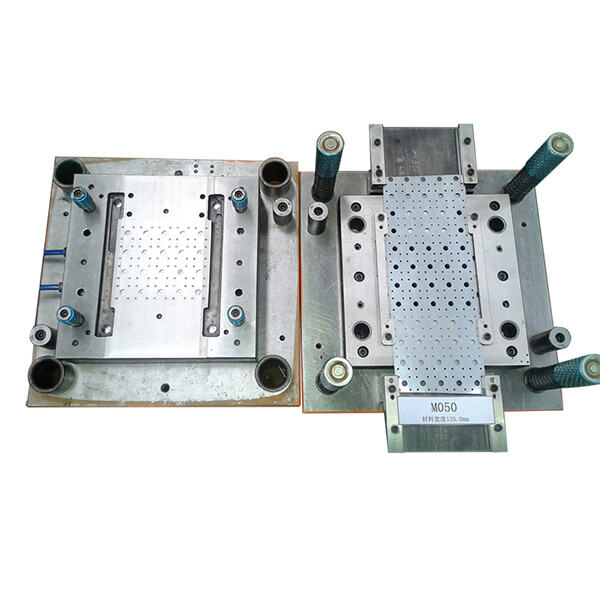

Stamping mold is a key tool for shaping and forming various designs. It's like a cookie cutter that stamps out shapes from a material such as metal or plastic. In the text, we will know what the stamping mold is and how to use it to work more easily in making things.

A stamping mold is designed to rock up and down to press the material into the desired shape. This is a method commonly employed at companies that manufacture cars, airplanes and electronics. In the car industry, for instance, stamping molds are used to make parts like doors, hoods and fenders.

There are several considerations to take into account when designing a stamping mould. The kind of mold is also very decisive in the stamping process, including the material of the mold. However, the mold design is a crucial point as it determines the appearance of the final product. The temperature and the pressure during stamping can also influence how well the final product is.

The design and manufacture of the stamping mold plays a decisive role in the success of production. The mold material should be selected based on what is being stamped. Mould should also be cleaned with and maintained in a good condition so that no trouble will be caused with the stamped goods. Finally, it's crucial to inspect the mold frequently for damages.

In order to have with you long-term reliable press die and keep them in good operating conditions, looking after them properly is vital. That’s having to clean and maintain the mold, and generally doing all I can to prevent any measure of wear, or at very least, damage. Plus, stamping with the proper temperature and pressure can also make the mold last longer.

Stamping molds have been integrated to make products as well, as technology continues to improve. New materials and new designs are continually being developed to make stamped products work better. Lihao and other companies are at the forefront of new stamping mold technology, dreaming up new ways to make things.