أجهزة فك اللفائف تنتمي إلى أفضل الآلات في مجال معالجة المعادن. وظيفتها هي تخفيف وتقويم المعادن الملفوفة مما يسهل استخدامها في عمليات التصنيع. اليوم، قد يكون الجميع يتطلعون لشراء أجهزة فك اللفائف لأنها تشكل المتطلب الأساسي لتيسير عملية معالجة المعادن. هناك بعض الأمور التي يجب مراعاتها عند التفكير في شراء جهاز فك لفائف. في هذا الدليل، سنساعدك على العثور على الصفقة المناسبة على جهاز فك اللفائف وسنشارك بعض النصائح حول كيفية اختيار الجهاز الذي يناسب ميزانيتك بسهولة.

سمك وحجم圈: الآن اأخذ في الاعتبار مدى سماكة وحجم الدائري لل圈 التي ستقوم بفكها. بعض منشآت فك circles مصممة لدوائر أكثر سمكاً، وبعضها الآخر لدوائر أكثر رقة. هذا سيوجهك في اختيار منشأة فك الدوائر المثالية المناسبة لغرضك.

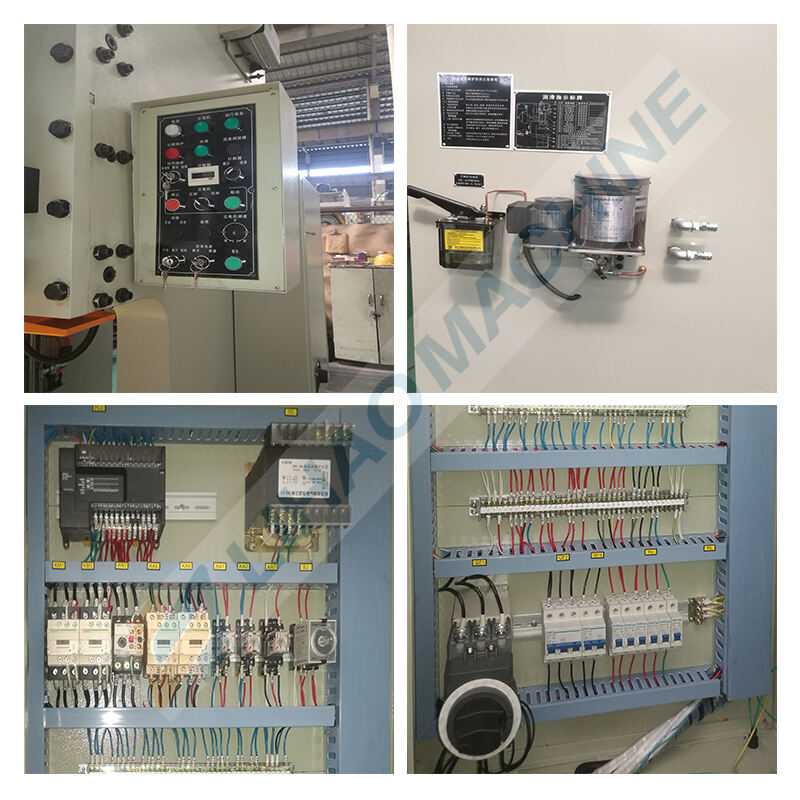

مصدر الطاقة — وأخيرًا، احرص على اختيار مصدر الطاقة الذي ستستخدمه لجهاز فك اللفائف. بعض الآلات تعمل بالكهرباء، بينما قد تعمل الأخرى بأنواع أخرى من الأنظمة. وهذا يؤكد أيضًا أن معرفة متطلبات الطاقة الخاصة بك ستساعدك على تحديد النوع المناسب من جهاز فك اللفائف.

حسنًا، السعر الجيد لجهاز فك الحزم يأخذ في الاعتبار العديد من العوامل. يجب أن تقارن بالتأكيد الأسعار من بائعين مختلفين. هذا سيساعدك للحصول على أفضل صفقة ممكنة. لكن، ليس الأمر فقط متعلقًا بالسعر، عليك أيضًا أن تأخذ في الاعتبار جودة الجهاز وسمعة البائع.

تتخصص شركة Lihao في إنتاج أجهزة فك الحزم ذات الجودة العالية وبأسعار تنافسية. فريق الخبراء في Al Murooj مستعد لمساعدتك في اختيار جهاز يلبي احتياجاتك الدقيقة. لديهم أيضًا خدمة عملاء ودعم جيدين، وهو أمر حاسم عند شراء منتج.

إذا كنت تبحث عن شراء جهاز فك الحزم، فمن الجدير بك أن تكون لديك معرفة بأنواع المختلفة التي توجد. يتم تصنيع كل جهاز فك حزم لمجموعة معينة من التطبيقات، وتختلف الأحجام والتكوينات. أنواع مختلفة لأجهزة فك الحزم. إليك 6 من أكثر أنواع أجهزة فك الحزم شيوعًا التي ستواجهها:

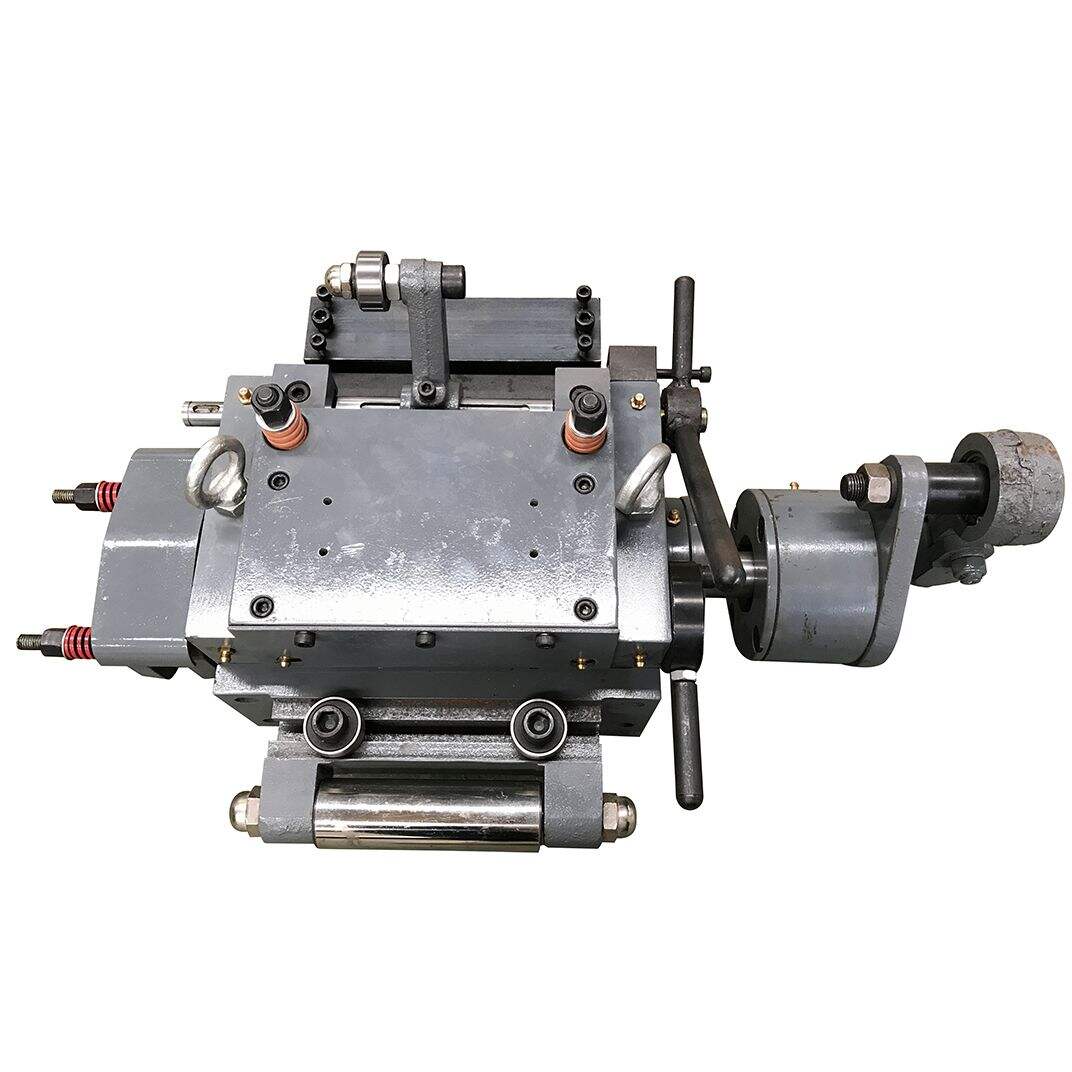

أجهزة فك لفائف الحديد باستخدام المحركات الكهربائية: هذه الآلة تساعد في فك اللفائف عن طريق مساعدتك على تسوية المواد على خط الإنتاج باستخدام محرك كهربائي. هذه الأجهزة أكثر كفاءة وستكون مناسبة لللفائف الكبيرة أو التطبيقات ذات الحجم العالي التي تتطلب منك فك كميات كبيرة من المادة بسرعة.

نحن نتفوق في مجال هندسة تصاميم الأدوات المتينة، مما يقلل إلى أدنى حد من التعديلات المطلوبة على تجهيزاتك، وبالتالي يقلل من إنتاج الهدر. ونقدّم عروض أسعار لآلات فك اللفائف لدينا مع خدمة تركيب وتدريب عالمية تضمن دمجًا سلسًا وأداءً مُثلى في جميع أنحاء العالم. وبفضل التصنيع الداخلي ودعم قطع الغيار عالية الجودة، نضمن أقل انقطاع ممكن وأعلى مستويات الإنتاجية. وقد حصلنا على شهادة ISO 9001 وشهادة CE المعتمدة من الاتحاد الأوروبي.

التزامنا بالموثوقية والابتكار وتحسين منتجاتك وخدماتك بشكل مستمر هو إجراء مستمر. فريق ليهاو لديه خبرة كبيرة في تقديم أنظمة متقدمة. كنا دائمًا الحل الأبرز في مجال تطوير التلقائيات. نركز بشدة على رضا العملاء من خلال تقديم المنتجات والخدمات الأفضل باستمرار.

توفر Lihao Machine حلول مخصصة بالإضافة إلى خدمة كاملة لتلبية مختلف احتياجات العملاء. يمكنك توقع حلول متكاملة تغطي التصميم والإنتاج والمبيعات. فريق البحث والتطوير لدينا يقدم لك خيارات مخصصة ومناقشات تقنية لضمان أن كل خيار سيكون مناسبًا لمعاييرك الفريدة.

تعد شركة Lihao Machine الرائدة في السوق منذ 26 عامًا. إنها المزود الموثوق به لكل من الأسواق المحلية والدولية. يتم استخدام منتجاتنا على نطاق واسع في العديد من الصناعات حول العالم. نقدم لعملائنا في جميع أنحاء العالم خدماتنا من خلال حوالي 20 مكتبًا في الصين وفرع في الهند. نقدم حلولًا مخصصة لعدد كبير من الصناعات باستخدام إمكانياتنا التكنولوجية المتقدمة.