What key things to consider while choosing the best Mechanical Press Machine. Look at these important aspects and then decide since it will matter in future for your business.

Constructing and the material: You are going to use how strong your construction is, will directly affect on pressure what machine has to apply. The type of materials youll be cutting is another important consideration to ensure that your chosen machine will handle them as efficiently as possible. It does not matter if it is made of metal, plastic or other materials; you will need to make sure that the machine and material complement each other in order to get the best out of them.

Capacity: The capacity of mechanical press machine is measured based on its tonnage like maximum pressure it can apply. Signal strength Going for a higher tonnage machine will definitely mean that the equipment is strong and sturdy, designed to handle heavy-duty use. This power is important to keep the operations of your business functioning smoothly.

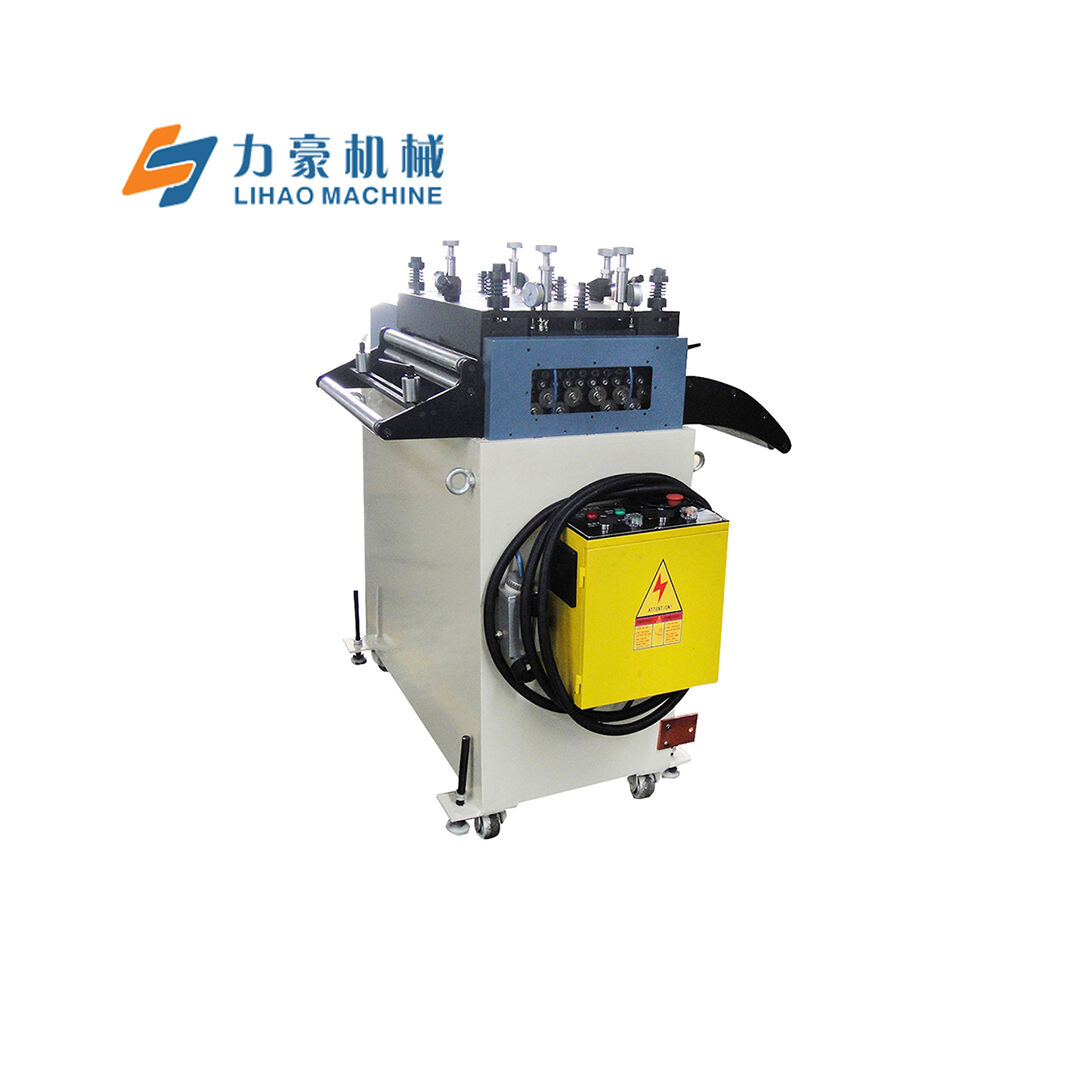

Footprint: Take into account how much production floor space you have to work with when choosing a mechanical press machine, similar to the Lihao's product like slitting cutting machine. Size - This is something very critical to the operation and efficiency of the machine. No one wants to be stuck with a big machine that does not fit into the workshop, this will only make production processes inefficient and workflow more of problem.

Application: Consider the type of products that you plan to mass-produce with a machine and how accurate each product needs to be finished. Once you determine the way you will use your machine, it allows narrowing down and getting a model that perfectly fits into achieving optimal production.

Just search the web for good brands and it will help in guiding you. Renowned for providing robust and versatile machines across a wide range of industrial applications. A reputable brand that manufactures high-precision and durable machines to cater various other industrial requirements. Structuring user-friendly devices, within reach of all businesses (including small), that are easy to operate and maintain.

The mechanical press machine could last for a long time, but even the most insignificant lack of maintenance can affect its performance, as well as the Lihao's cut to length machine. Here we present to you a list of things that one should include in their daily routine while taking care of and maintaining the equipment:

Lubricate: Lubricating the moving parts of your machine will also make them last longer and perform better.

Clean - Keep the machine and its parts clean to avoid dust collection that will otherwise damage your bandsaw.

Inspect - Perform regular inspections to catch any problems sooner and resolve them more quickly, preventing downtime.

Replace parts: Ensure that you remain as proactive to replace the worn belts, screws and bearing etc. so your machine keeps working fine at all times.

The use of a mechanical press machine in the manufacturing process presents numerous and major benefits, identical to progressive die developed by Lihao. The following are some of the major benefits linked to these machines:

Mechanical press machines are a great choice for high production scenarios in which mass manufacturing is being carried out with efficiency at very high output rates.

Accuarity: Despite working with tough material, precision of accurate parts produced are achieved by these machines.

Advantages: As they are quite robust mechanically, mechanical press machines do not need much more frequent repair and thus experience less downtime.

Flexibility: The flexibility of these machines, enabling them to process a wealth of materials makes it ideal for variety industries and applications.

Knowing common problems and troubleshooting it during operational challenges is important to keep the machine run perfectly, same with Lihao's metal stamping dies. Answered - Typically most common problems and their solutions.

Machines Jams: Clear all jams by removing obstructions, please replace any failure parts to restore machine back in service.

Maintenance: Avoid overuse and maintain lubrication for the machine components to prevent overheating.

Performance Improvement: Realignment or parts replacement used to increase machine performance and effectiveness.

In closing, choosing the best mechanical press machine for your needs and committing to a proper maintenance schedule are crucial components in providing optimal efficiency, productivity and cost-effectiveness as part of manufacturing practices. Now you can legally decide which would best suit your business goals and production needs.

Lihao Machine provides tailored solutions comprehensive service meet up with the diverse needs of customers. Offering a selection of products, including 3 in 1 feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we offer incorporated services covering production design purchases, service plus trading. Our R&D team is dedicated to ensuring that the option is had by you of customizing your choices and technical discussions making sure that every solution is perfectly tailored to your requirements.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our Mechanical press machine offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.